Printing slurry and production process of three-dimensional micro-current membrane cloth

A production process and micro-current technology, applied in the direction of manufacturing tools, additive processing, metal processing equipment, etc., can solve problems such as failure to meet production requirements, product use effects of production indicators, inability to add solid materials, and limited effects. It is conducive to mass production, the production process is smooth and smooth, and the effect of avoiding the jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0055] A printing paste of three-dimensional microcurrent film cloth, calculated according to the total amount of the printing paste, includes the following components and contents:

[0056]

[0057] Wherein, calculated according to the proportion of the functional material, the functional material includes:

[0058] components Example 1 / % Example 2 / % Biomagnetic powder 40 60 infrared powder 30 30 negative ion powder 30 10

[0059] It should be noted that the biomagnetic powder and the infrared powder used in the present invention all have specific frequencies (for example, the magnetic frequency of the biomagnetic powder in Embodiment 1 is 0.9MT, and the wavelength of the infrared powder is 980nm), so as to form a three-dimensional microcurrent Finally, the generated electric waves can enter the compartments of skin cells to obtain the most suitable skin care and beauty effects. The 3D printing paste provided by the present invention...

Embodiment 3-4

[0061] A printing paste of three-dimensional microcurrent film cloth, calculated according to the total amount of the printing paste, includes the following components and contents:

[0062]

[0063] Wherein, calculated according to the proportion of the functional material, the functional material includes:

[0064] components Example 1 / % Example 2 / % Biomagnetic powder 60 50 infrared powder 20 10 negative ion powder 10 20 Electronic thermal powder 5 10 Toner 5 10

[0065] It should be noted that the biomagnetic powder and infrared powder used in the present invention all have specific frequencies (for example, in embodiment 3, the magnetic frequency of the biomagnetic powder is 0.1MT, and the wavelength of the infrared powder is 250nm). After forming a three-dimensional microcurrent , the generated electric waves can enter the compartments of skin cells to obtain the most suitable skin care and beauty effects. The 3D pr...

Embodiment 5

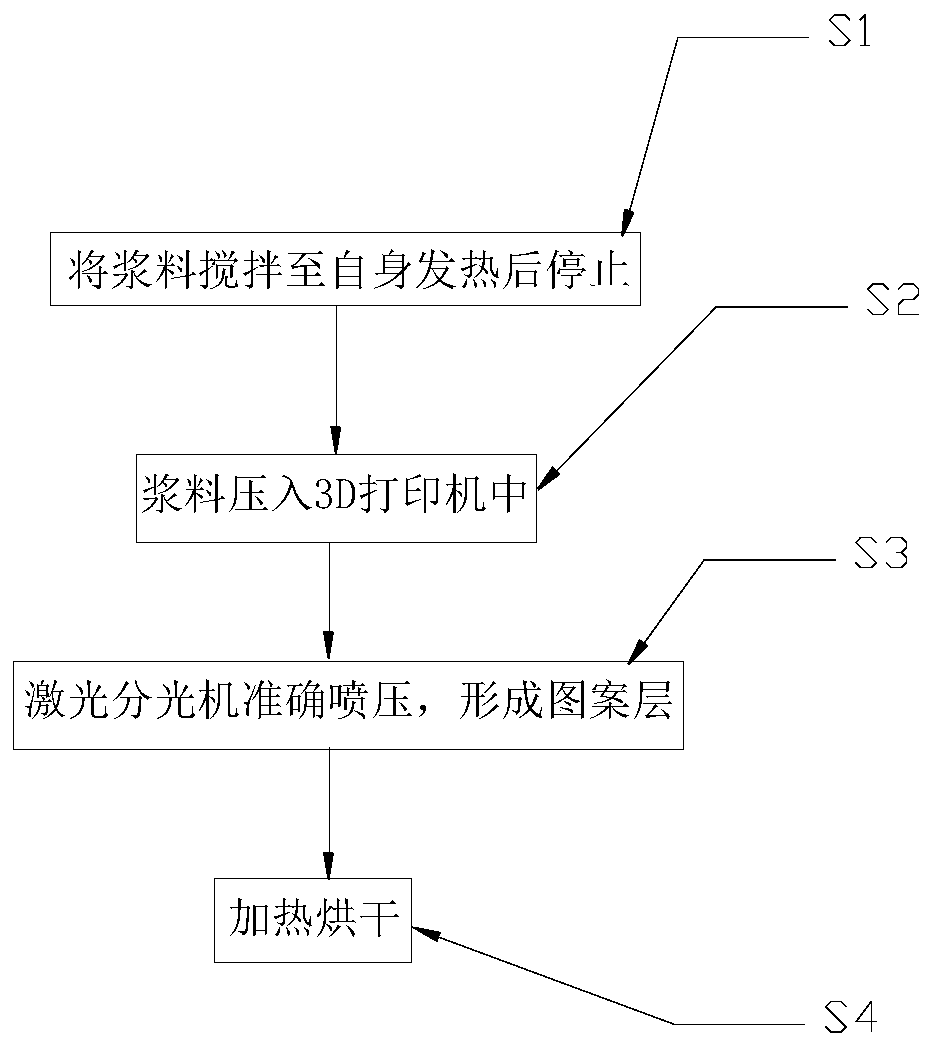

[0067] refer to figure 1 Shown, a kind of printing production technology of three-dimensional microcurrent membrane cloth, it comprises the following steps:

[0068] S1 Stirs the slurry of Example 1 or 2 to stop after self-heating;

[0069] S2 transfers the slurry to an air pressure tank to press the slurry into the 3D printer by air pressure;

[0070] S3 uses a laser spectrometer to accurately spray the slurry ejected from the 3D printer on the fabric to form a pattern layer;

[0071] S4 sends the cloth of step S3 into a dryer for heating and drying.

[0072] The stirring time in step S1 is 30-45 minutes, and the printing paste is stirred until the self-heating temperature reaches 40°C-60 and then stops. In Example 5, the stirring time is 30 minutes, and the self-heating temperature is 50°C. stop.

[0073] In step S3, the electromagnetic light of the laser spectrometer reacts with the infrared light of the printing paste, thereby accurately spraying and pressing.

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com