MXene@CS@PDMS three-dimensional porous composite material and preparation method and application thereof

A composite material, three-dimensional technology, applied in the application field, can solve the problems of large sensor use limitations, difficult to achieve mass production, cumbersome preparation methods, etc., to achieve the effect of small hysteresis, simple method and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

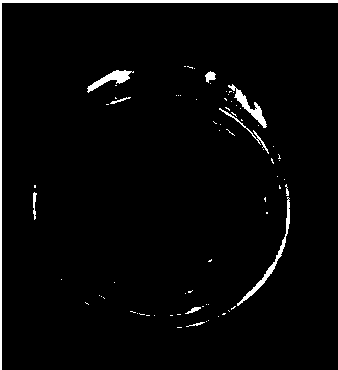

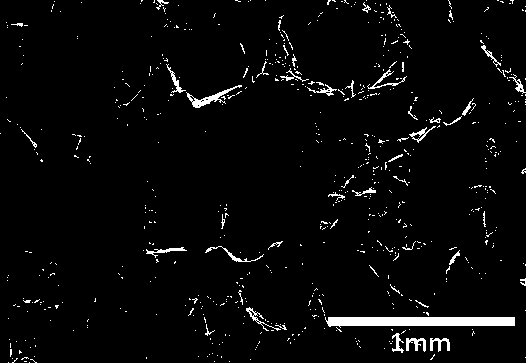

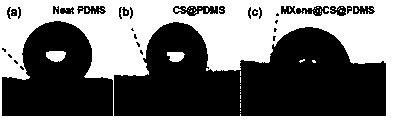

Image

Examples

Embodiment 1

[0047] The preparation method of MXene nanosheets is as follows:

[0048] (1) Add 10ml of deionized water to a polytetrafluoroethylene container and ice bath to reduce the temperature of the deionized water to below 5℃. Under the condition of magnetic stirring, slowly add 20ml, 9 moles of HCl per liter, and continue stirring Reduce the temperature to below 5 degrees Celsius, add 1g LiF and stir for 1h;

[0049] (2) Slowly add 1gMAX precursor to the polytetrafluoroethylene container;

[0050] (3) After the MAX precursor is added, the temperature is naturally raised to room temperature for about 30 minutes, and then the temperature is raised to 35°C, and the reaction is maintained for about 25 hours;

[0051] (4) Centrifuge the reacted product at 3500 rpm for 5 minutes and repeat it several times until the pH of the supernatant is greater than 6;

[0052] (5) Collect the final neutral or nearly neutral suspension, and peel it off ultrasonically under argon protection;

[0053] (6) Centrif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com