Gas liquefaction experimental device and method for supercritical water-gas containing coal

A supercritical water and experimental device technology, applied in the process, chemical instruments and methods, measurement devices and other directions under supercritical conditions, can solve the problems of retention, lack of research on gas-containing gas-liquid conversion, etc., to improve the utilization of the reaction rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further illustrated by the following examples, but not limited to the following examples.

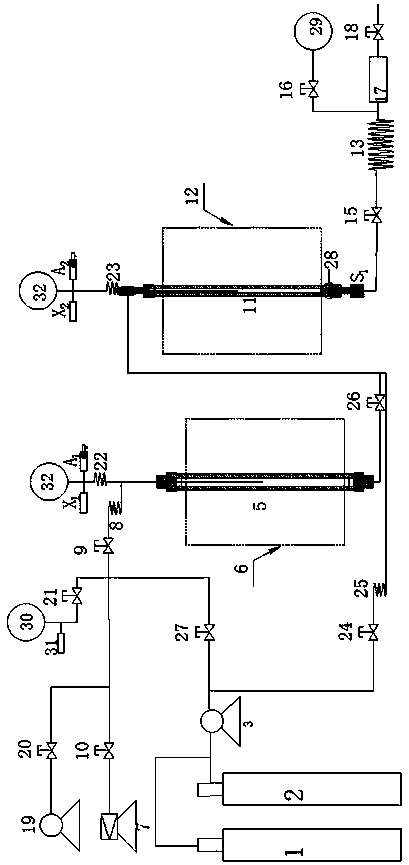

[0046] Such as figure 1 As shown, a supercritical water-gas liquefaction experimental device for gas-containing coal includes a high-pressure gas supply device, a supercritical water generation device, a coal gas liquefaction device, a pressure monitoring device, and a vacuum device;

[0047] The gas supply device includes a helium cylinder 1, a gas cylinder 2, and a gas booster pump 3, wherein the helium cylinder 1 and the gas cylinder 2 are respectively connected to the gas booster pump 3 through a stainless steel high-pressure coil 4 ;

[0048] The supercritical water generating device includes a supercritical medium generating kettle 5, a muffle furnace heater 6, a satellite constant flow liquid booster pump 7, and a temperature sensor; wherein the supercritical medium generating kettle 5 is placed inside the muffle furnace heater 6 , the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com