Metal formate/carbon nanotube lithium ion battery negative electrode material and preparation method thereof

A lithium-ion battery, metal formate technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low electronic and ionic conductivity, low discharge specific capacity, and increased material polarization, and achieve high Effects of specific capacity, sufficient compounding, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

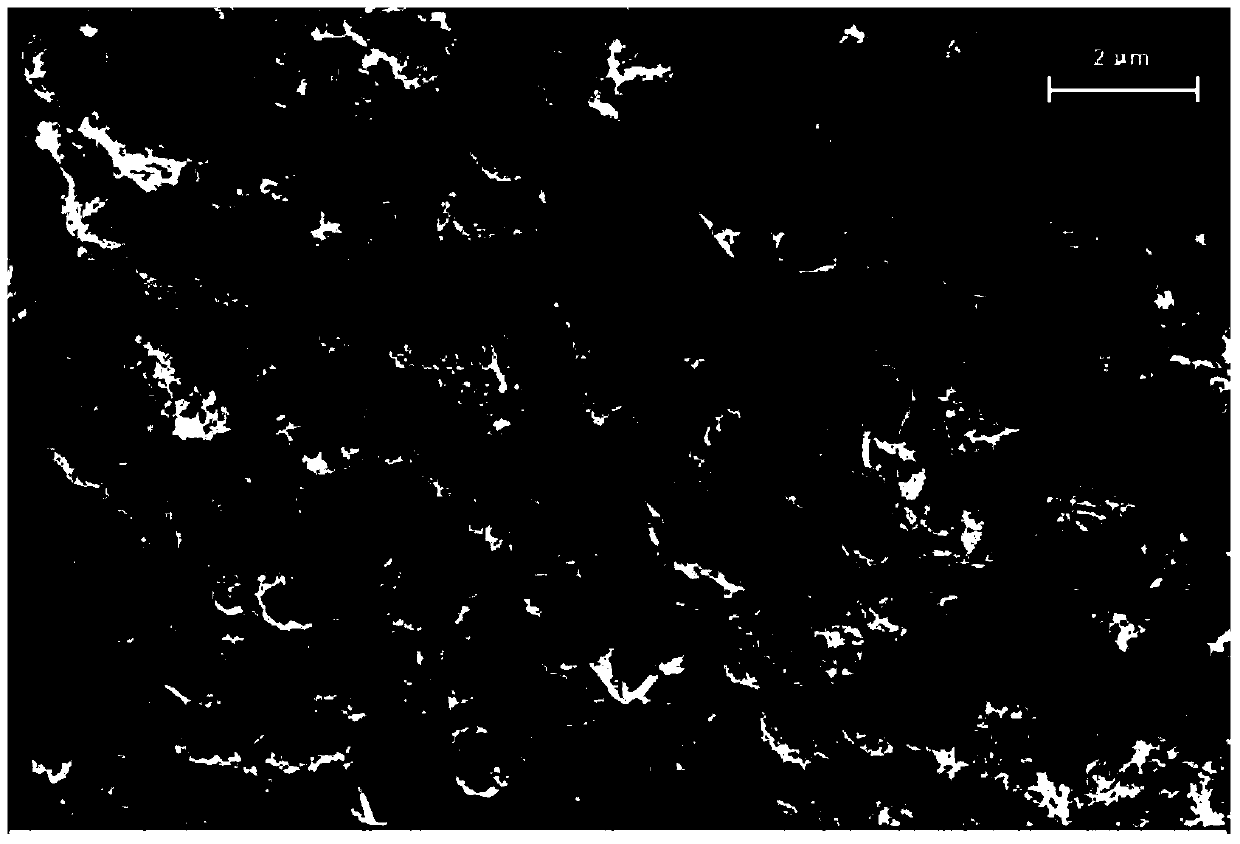

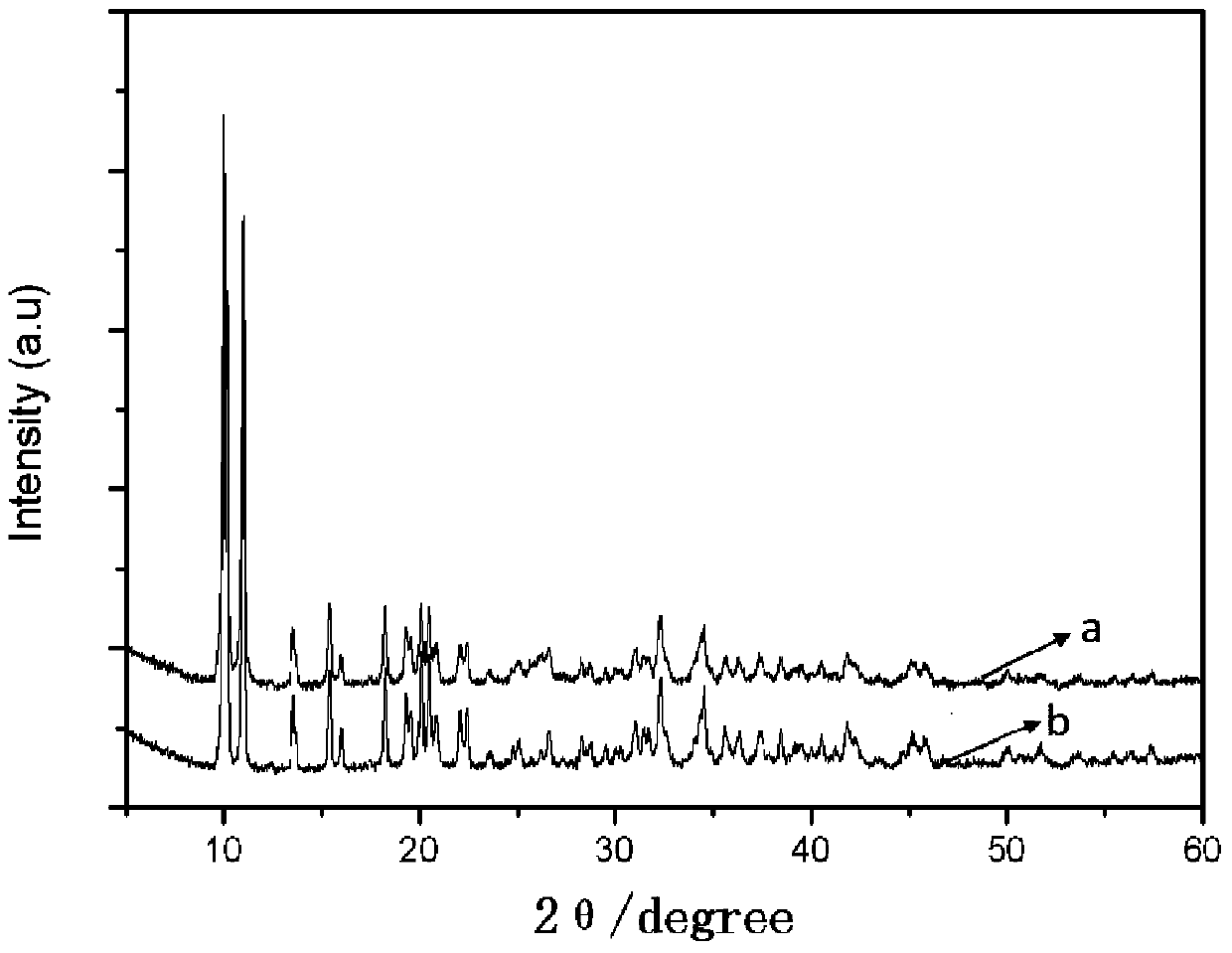

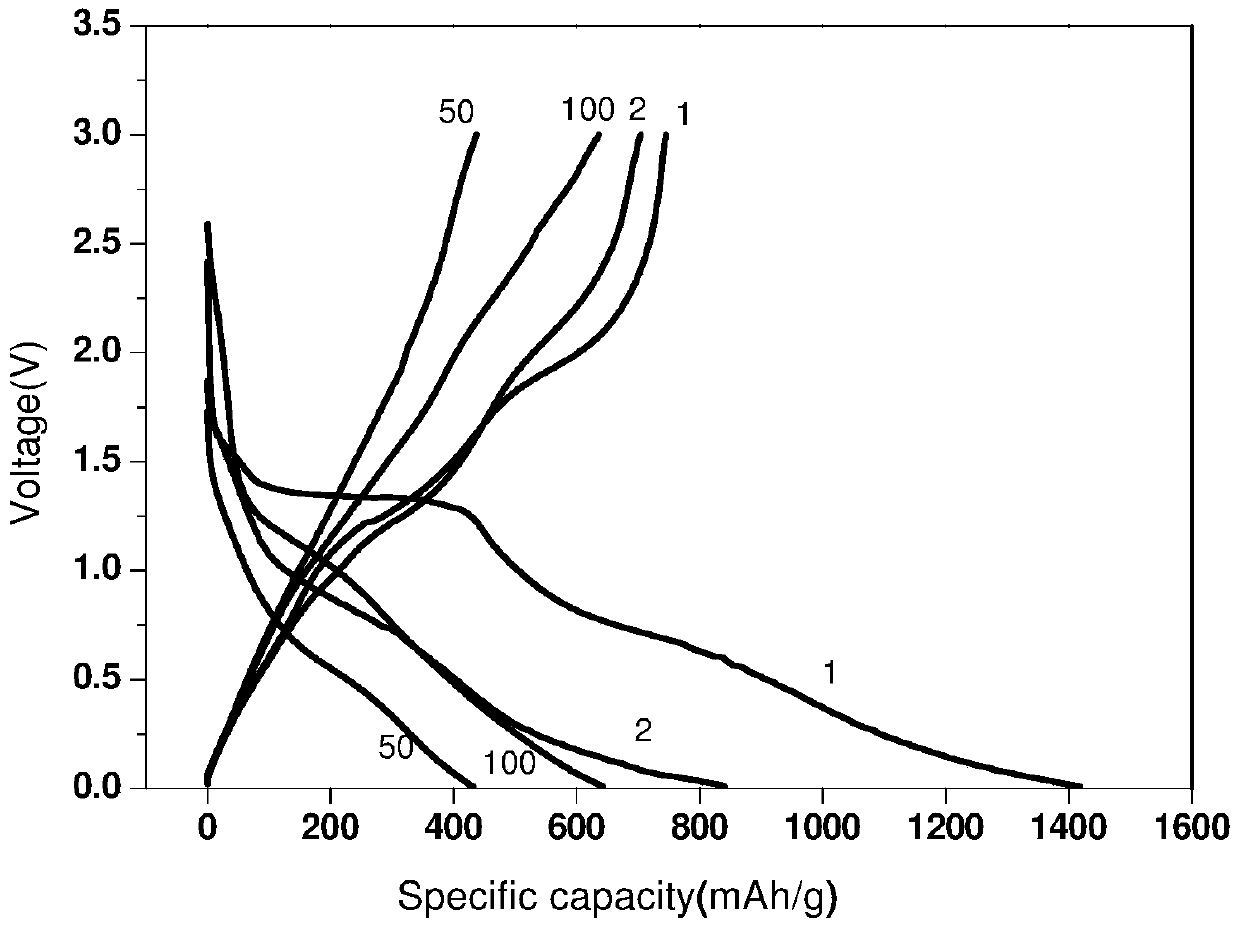

Image

Examples

Embodiment 1

[0036] (1) take by weighing 5.678g nickel nitrate hexahydrate, 5ml purity be 88% formic acid (molar ratio 1: 6.7) at room temperature, add and fill 40ml N, in the beaker of N-dimethylformamide solvent, stir 30min, Mix the two evenly to obtain a mixed solution;

[0037] (2) Mix 0.0061 g of acidified carbon nanotubes and 9 ml of N, N-dimethylformamide in a beaker; stir at room temperature for 10 minutes, ultrasonically disperse for 30 minutes, repeat stirring and ultrasonically dispersing 3 times until the acidified carbon nanotubes are uniformly dispersed, made into a suspension;

[0038] (3) Measure 1ml of the mixed solution in step (1) and mix it with the suspension in step (2), stir for 30 minutes to mix the two evenly, and transfer the mixed solution to a 25ml reaction kettle with a Teflon liner , stamped and sealed;

[0039] (4) After the reaction, the reaction kettle was placed in a programmed temperature-controlled oven, and kept at 100°C for 2 days;

[0040] (5) Cool...

Embodiment 2

[0042](1) take by weighing 5.678g nickel nitrate hexahydrate, 5ml purity be 88% formic acid (molar ratio 1: 6.7) at room temperature, add and fill 40ml N, in the beaker of N-dimethylformamide solvent, stir 30min, Mix the two evenly to obtain a mixture;

[0043] (2) Mix 0.0091g of acidified carbon nanotubes and 9ml of N, N-dimethylformamide in a beaker; stir at room temperature for 10 minutes, ultrasonically disperse for 30 minutes, repeat stirring and ultrasonically dispersing 3 times until the acidified carbon nanotubes are uniformly dispersed, made into a suspension;

[0044] (3) Measure 1ml of the mixed solution in step (1) and mix it with the suspension in step (2), stir for 30 minutes to mix the two evenly, and transfer the mixed solution to a 25ml reaction kettle with a Teflon liner , stamped and sealed;

[0045] (4) After the reaction, the reaction kettle was placed in a programmed temperature-controlled oven, and kept at 100°C for 2 days;

[0046] (5) Cool down to...

Embodiment 3

[0048] (1) take by weighing 5.678g nickel nitrate hexahydrate, 5ml purity be 88% formic acid (molar ratio 1: 6.7) at room temperature, add and fill 40ml N, in the beaker of N-dimethylformamide solvent, stir 30min, Mix the two evenly to obtain a mixture;

[0049] (2) Mix 0.0122g of acidified carbon nanotubes and 9ml of N, N-dimethylformamide in a beaker; stir at room temperature for 10 minutes, ultrasonically disperse for 30 minutes, repeat stirring and ultrasonically dispersing 3 times until the acidified carbon nanotubes are uniformly dispersed, made into a suspension;

[0050] (3) Measure 1ml of the mixed solution in step (1) and mix it with the suspension in step (2), stir for 30 minutes to mix the two evenly, and transfer the mixed solution to a 25ml reaction kettle with a Teflon liner , stamped and sealed;

[0051] (4) After the reaction, the reaction kettle was placed in a programmed temperature-controlled oven, and kept at 100°C for 2 days;

[0052] (5) Cool down to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com