A kind of preparation technology of methyltrimethoxysilane

A technology for the preparation of methyltrimethoxysilane, which is applied in the field of preparation of methyltrimethoxysilane, can solve problems such as ineffective treatment or utilization, increased pressure in storage containers, hidden safety hazards, etc., and achieve circular supply chain, high utilization rate and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

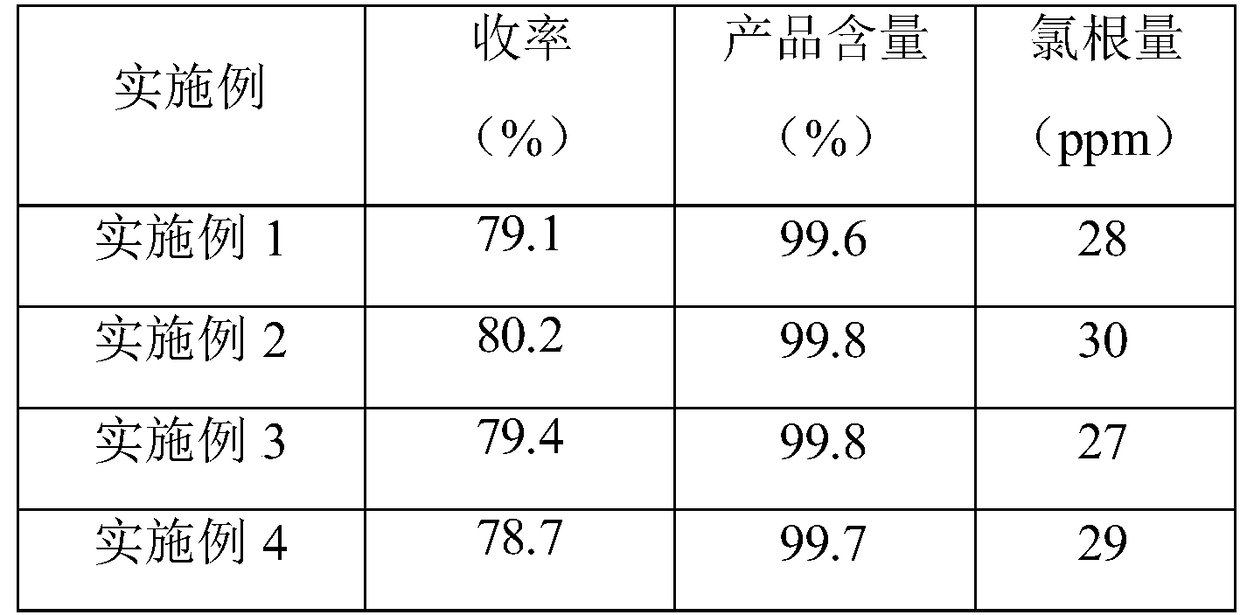

Examples

Embodiment 1

[0027] Follow the steps below to prepare methyltrimethoxysilane:

[0028] A. Alcoholysis dechlorination dehydrogenation

[0029] At room temperature, use a metering pump to continuously pump 200kg of methanol into the reactor filled with 249kg of monomethylhydrodichlorosilane, and the feeding time is 2h; 3 The speed of / h is passed into N 2 , keep the temperature of the reaction solution at 25±2° C., and carry out the alcoholysis dechlorination and dehydrogenation reaction. After 4 hours of reaction, no obvious acid gas escaped, and the reaction was completed, and nitrogen flow was stopped.

[0030] B. Post-processing

[0031] Add the sodium methoxide methanol solution with a mass fraction of 29% into the reaction kettle to stir and carry out the neutralization reaction until the pH of the reaction solution reaches 7; filter and remove the sodium chloride salt generated by the neutralization reaction, and the filtrate is the crude methyltrimethoxysilane . The crude methyl...

Embodiment 2

[0034] Follow the steps below to prepare methyltrimethoxysilane:

[0035] A. Alcoholysis dechlorination dehydrogenation

[0036] At room temperature, use a metering pump to continuously pump 207kg of methanol into a reaction kettle filled with 250kg of monomethylhydrodichlorosilane, and the feeding time is 4h; 3 The speed of / h is passed into N 2 , heat up, make the temperature of the reaction solution reach 35±2°C, and carry out the alcoholysis dechlorination and dehydrogenation reaction. After reacting for 3 hours, no obvious acid gas escaped, and the reaction was completed, and nitrogen flow was stopped.

[0037] B. Post-processing

[0038] The sodium methoxide methanol solution with a mass fraction of 29% was added to the reactor and stirred for neutralization reaction until the pH of the reaction solution reached 8; the sodium chloride salt generated by the neutralization reaction was removed by filtration, and the filtrate was crude methyltrimethoxysilane. The crude ...

Embodiment 3

[0041] A. Alcoholysis dechlorination dehydrogenation

[0042] At room temperature, respectively pump 213kg of methanol and 249kg of monomethylhydrodichlorosilane into the reaction tower continuously with a metering pump at a rate ratio of 1:1.2. The feeding time is 6 hours, and the temperature of the reaction tower is kept at 35°C. The stripping tower is then sent to the neutralization tank, and the temperature of the stripping tower is 65-70°C.

[0043] B. Post-processing

[0044]Add the sodium methoxide methanol solution with a mass fraction of 29% into the neutralization tank containing the alcoholysis product and stir for neutralization reaction until the pH of the reaction solution reaches 8; the sodium chloride salt generated by the neutralization reaction is removed by filtration, and the filtrate is formazan crude trimethoxysilane. The crude methyltrimethoxysilane is rectified at atmospheric pressure, and the fraction at 103°C is collected to obtain high-purity methy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com