Color-based batching method for automobile coating workshop

A workshop and painting technology, applied in the field of production planning and scheduling of hybrid assembly lines, to achieve the effect of saving workshop area, reducing the number of color switching times, and eliminating construction and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

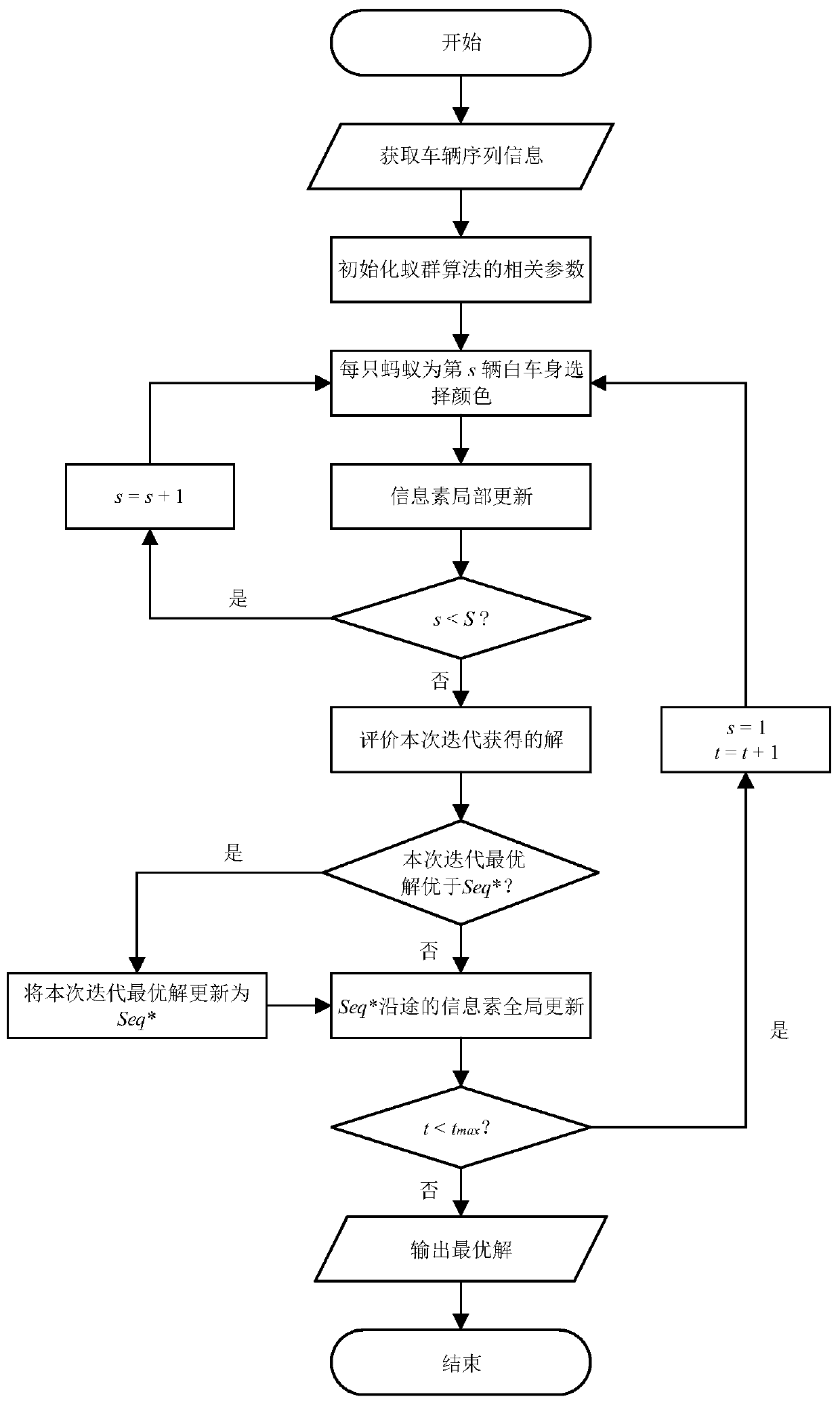

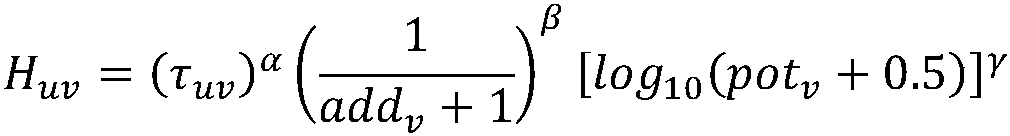

Method used

Image

Examples

Embodiment

[0094] The present invention adopts C++ language in Microsoft Visual Studio to compile executable programs, and its effect is illustrated through a group of numerical experiments. The sequence parameters in the example include number of vehicles (S), number of body types, and number of colors. Table 1 shows the average results (ie, the number of times of color switching) of 40 randomly generated original sequences under each parameter combination before and after being solved by the algorithm of the present invention. The results show that the ant colony optimization algorithm proposed by the invention can significantly reduce the number of color switching in the original sequence in a short period of time, and has a good effect of batching by color.

[0095] Table 1 The solution effect of ant colony algorithm

[0096]

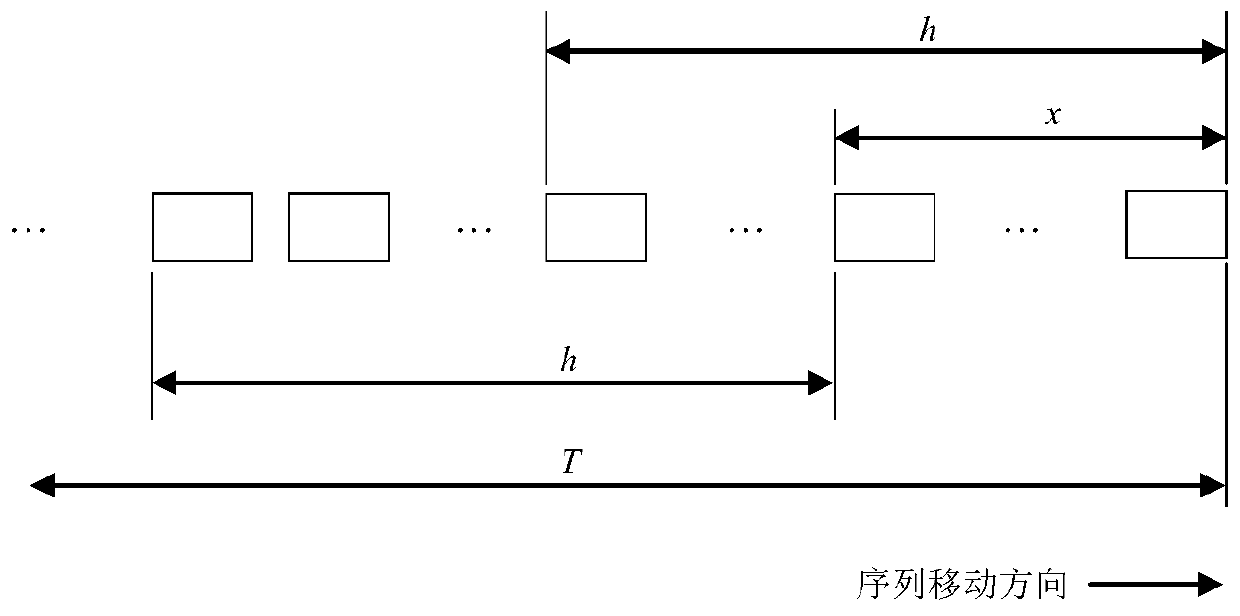

[0097] In addition, the invention also provides a rolling solution method for the large-scale color batching problem. The idea of the method is to deco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com