Detergent composition

A technology of composition and cleaning agent, which is applied in the direction of detergent composition, aerosol detergent composition, soap detergent composition, etc., and can solve problems such as blockage of distribution outlets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

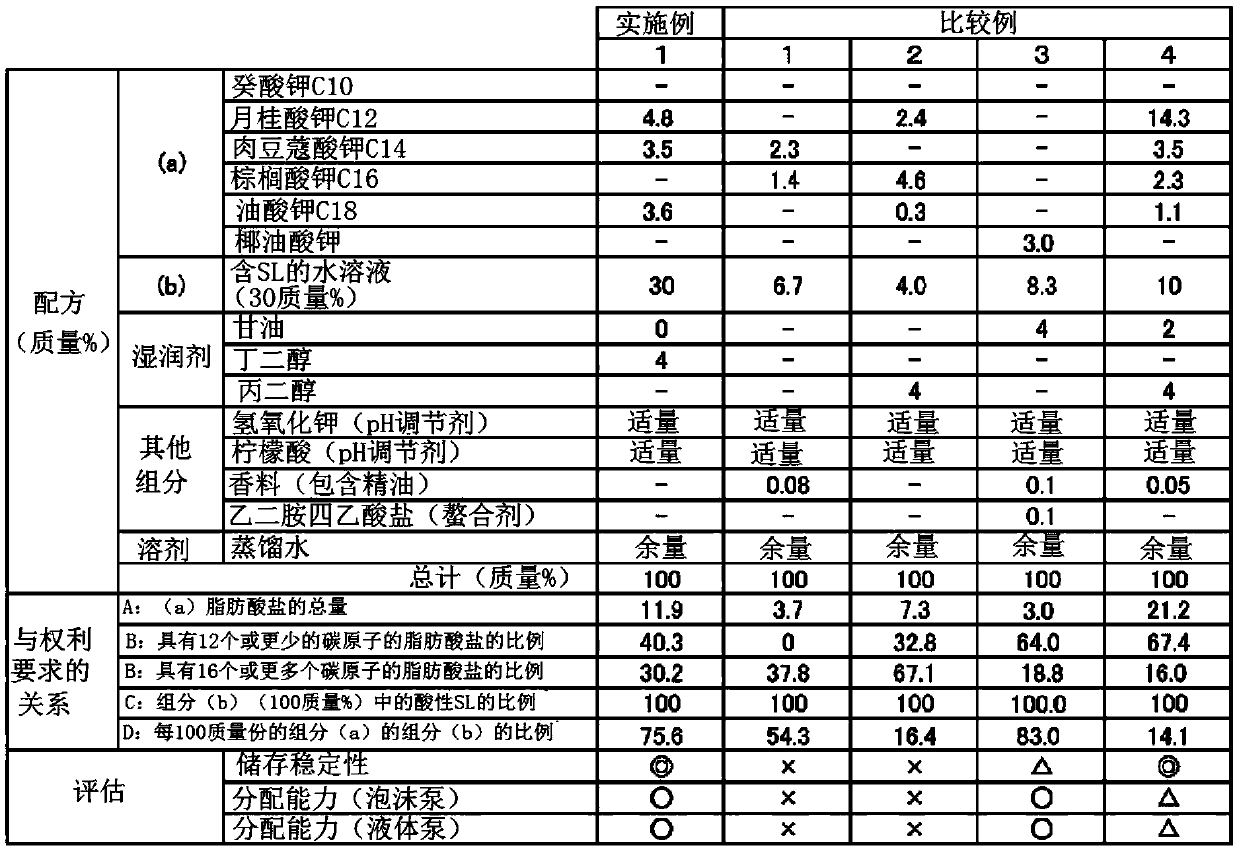

[0105] A preferred embodiment of feature F is as follows:

[0106] Based on 100 parts by mass of the total amount of component (a) contained in the detergent composition of the present invention,

[0107] (F-1) Proportion of one or more lauric acid salts: preferably 20 to 75 parts by mass, and more preferably 30 to 75 parts by mass;

[0108] (F-2) Proportion of one or more myristates: preferably 10 to 45 parts by mass, and more preferably 10 to 35 parts by mass;

[0109] (F-3) The ratio of the total amount of one or more palmitates and one or more oleates: preferably 5 parts by mass to 50 parts by mass, and more preferably 5 parts by mass to 40 parts by mass; And (F-4) The ratio of the total amount of fatty acid salts other than the above: preferably 0 to 8 parts by mass, and more preferably 0 to 5 parts by mass.

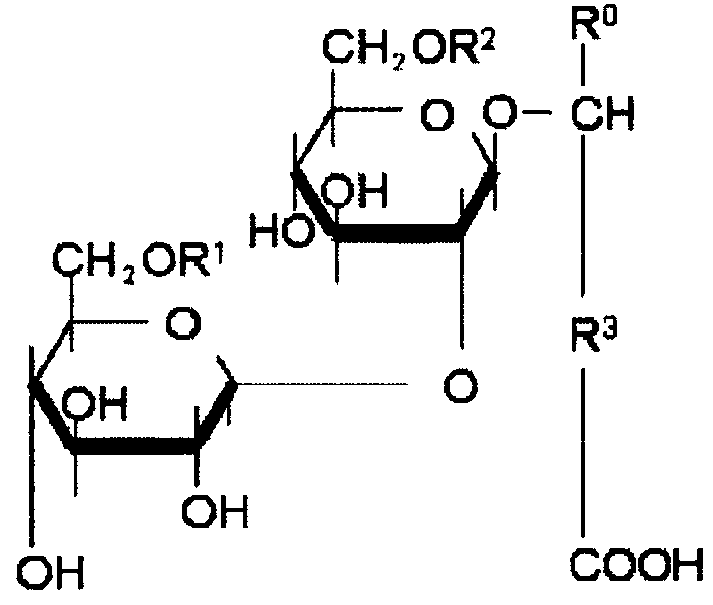

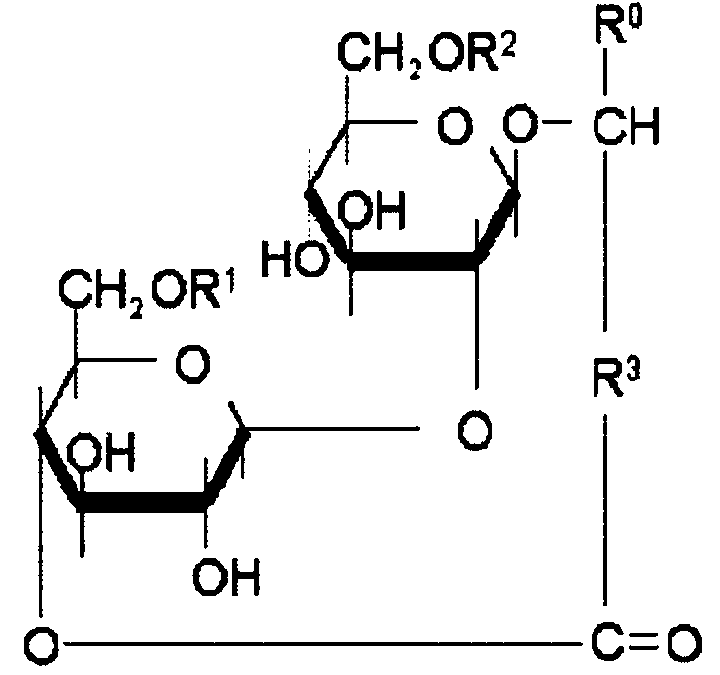

[0110] (b) Sophorolipid (SL)

[0111] SL of component (b) used in the detergent composition of the present invention is a glycolipid composed of hydroxy fatty ...

preparation example 1

[0162] Reference Preparation Example 1: Preparation of Sophorolipids

[0163] A product containing 10 g of aqueous glucose (manufactured by Nihon Shokuhin Kako Co., Ltd., product name: Nisshoku Gansui Kessho Budoto), 10 g of peptone (manufactured by Oriental Yeast Co., Ltd., product name: Peptone CB90M) and 5 g of yeast was used per liter A liquid medium of an extract (manufactured by Asahi Food & Healthcare Co., Ltd., product name: Meast Powder N) was used as a medium. Candida bombicola ATCC 22214 was cultured in the medium for two days while shaking at 30°C. Use it as a pre-culture solution.

[0164] Based on the total amount of the medium, the preculture solution was inoculated into the main medium (3 L) in a 5 liter fermenter in an amount of 4%, and then cultured at 30° C. for 6 days at an aeration rate of 0.6 vvm for fermentation. The main medium contains 100 g of aqueous glucose, 50 g of palm olein (produced by NOF Corporation, product name: Palmary 2000), 50 g of ol...

preparation example 2

[0166] Reference Preparation Example 2: Preparation of Acid Type SL

[0167] The SL obtained in the above Reference Production Example 1 (with a water content of about 50% by mass) was adjusted to pH 14 by adding an aqueous sodium hydroxide solution, and the resulting mixture was treated at 80° C. for 2 hours to undergo hydrolysis (alkaline hydrolysis). Subsequently, the hydrolyzate was returned to room temperature, and then adjusted to pH 11 by using sulfuric acid (9.8M aqueous solution). The resulting insoluble matter was removed by filtration to obtain a filtrate as an SL-containing aqueous solution. The SL-containing aqueous solution contained acid-type SL in an amount of 30% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com