Apparatus and method for continuously drying bulk goods, in particular wood chips and/or wood fibers comprising multi-fuel burner with a muffle cooling system

A wood fiber and equipment technology, applied in the field of bulk goods, can solve the problems of complex equipment and methods and high cost, and achieve the effects of simple equipment, increased effectiveness, and good energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

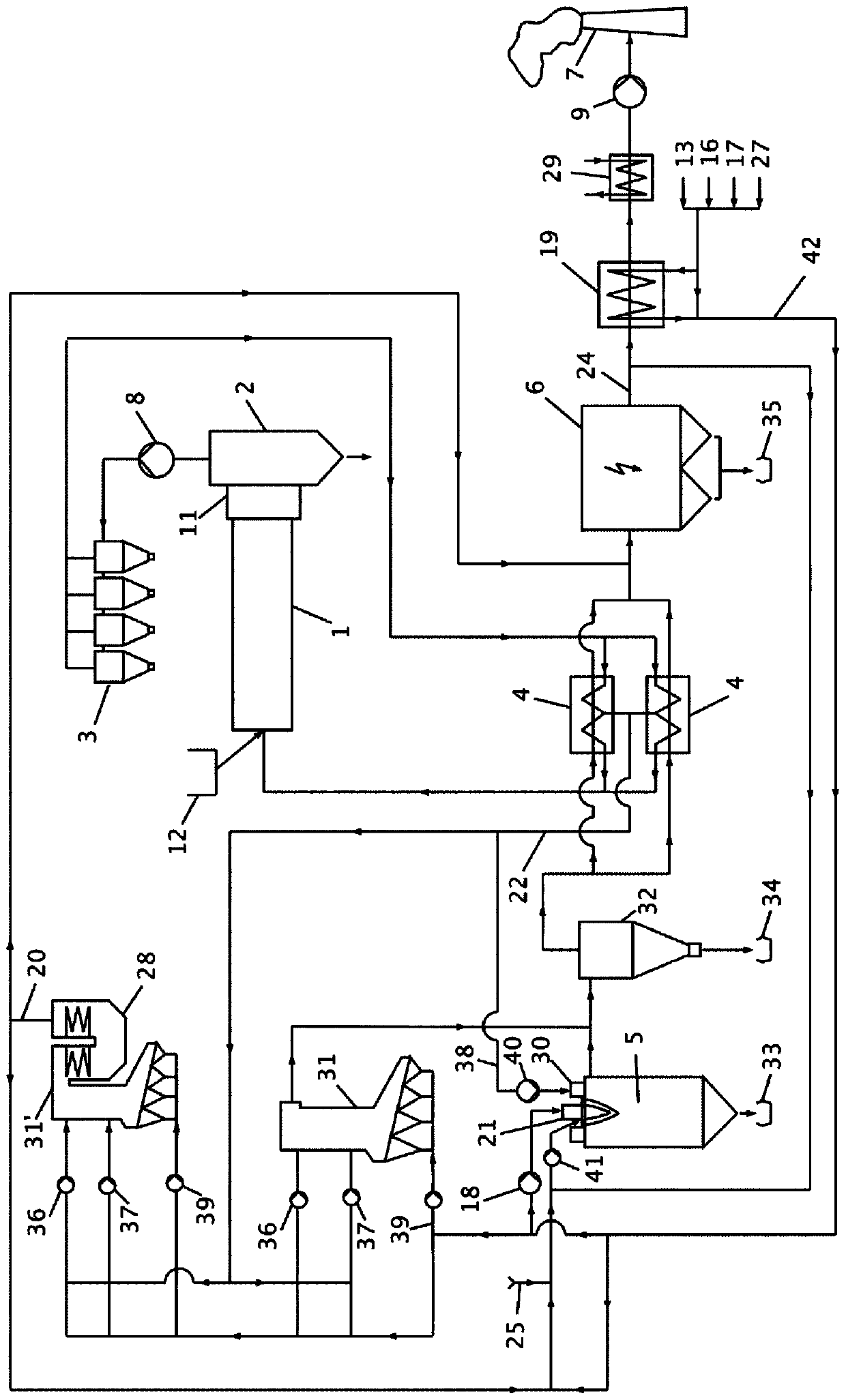

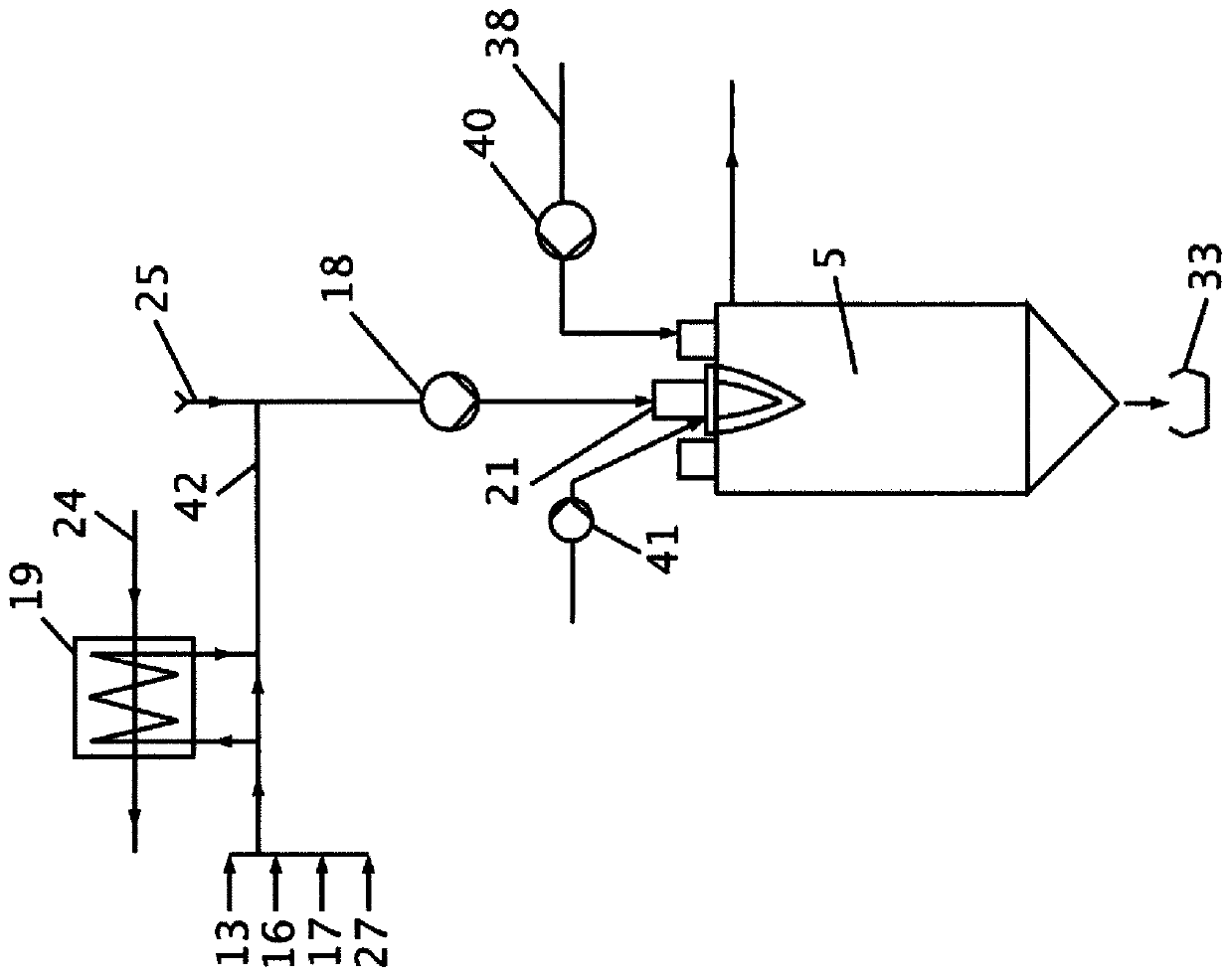

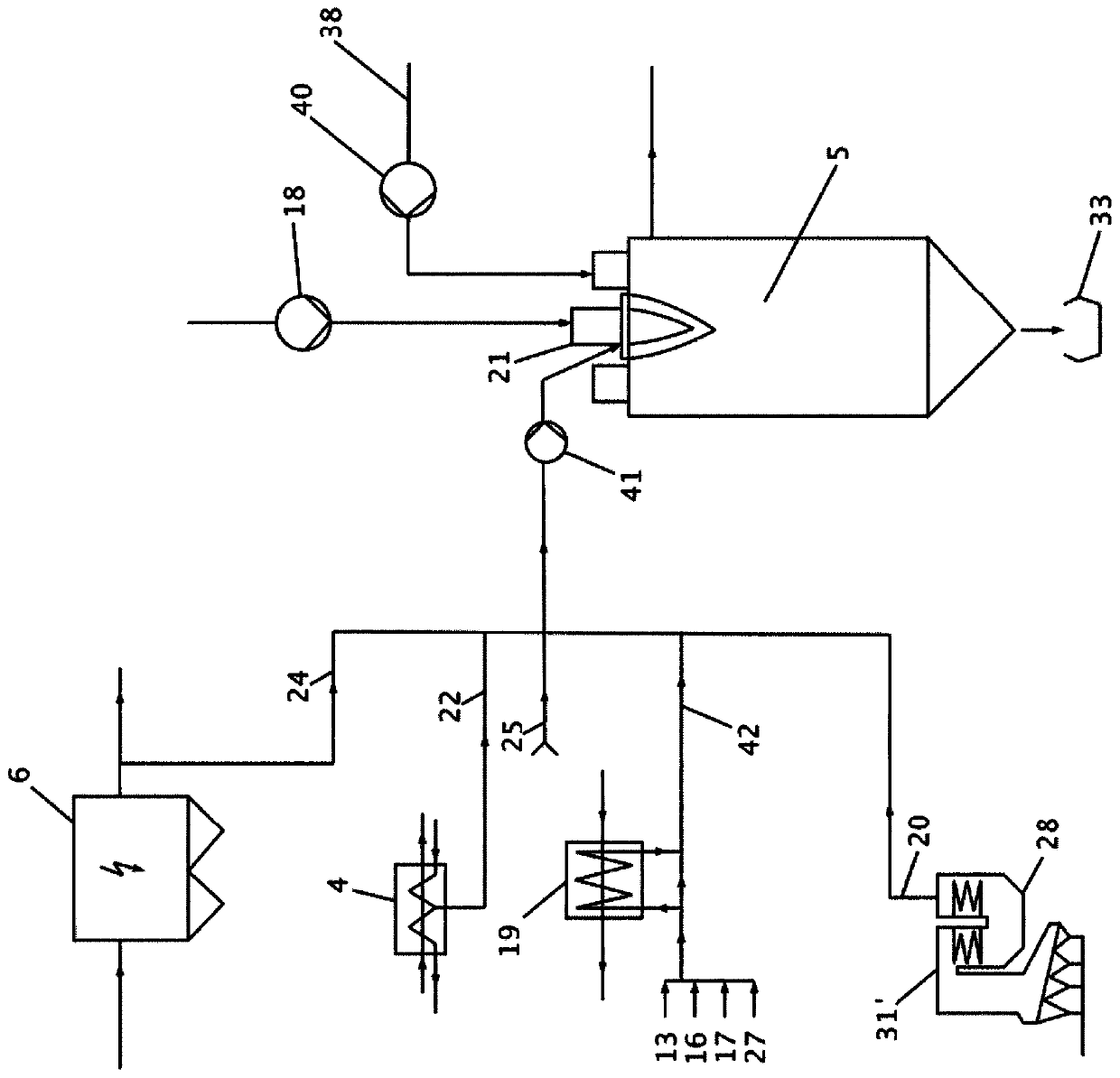

[0086] figure 1 A first example of the apparatus of the present invention is shown in the present invention is shown. The apparatus includes a drum type dryer 1, a discharge housing 2, a cleaning device 3 (multi-tube cyclone separator), two heat exchanger 4 parallel, has a combustion chamber for fuel / combustion air mixture. Multi-fuel burner 5, filter 6, and chimney 7. Dry steam generated by, for example, wood chips within the drying drum dryer 1 is introduced into the dry circuit. The dry steam fan 8 is disposed between the drum dryer 1 and the cleaning device 3, and the burner exhaust fan 9 is disposed between the filter 6 and the chimney 7. The dryer 1 can be provided with a deceleration region 11 and a metering device 12.

[0087]A bulk article is supplied to the drum dryer 1, such as wood chips and / or wood fibers. The drying gas supplied to the drum dryer 1 is heated via a heat exchanger 4 and has a temperature in the range of from about 250 ° C to about 600 ° C. The dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com