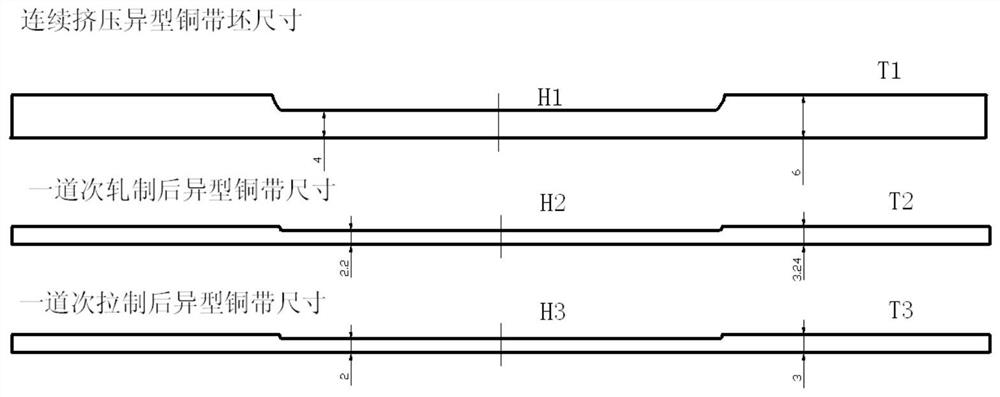

A kind of production method of special-shaped copper alloy strip

A technology for copper alloy strips and production methods, applied in furnace types, furnaces, heat treatment equipment and other directions, can solve problems such as poor mechanical properties, poor surface quality, long process flow, etc., to ensure dimensional accuracy, eliminate plate shape difference, size high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in combination with specific embodiments.

[0042] (1) Upward continuous casting

[0043] A power frequency smelting device is used for upward continuous casting of copper rods. The smelting device includes a melting furnace, a holding furnace, a traction device, and a coiling device.

[0044] The traction device includes crystallizer, graphite mold, sheath and traction motor.

[0045] The graphite mold is installed at the bottom of the crystallizer, and the joint between the graphite mold and the bottom of the crystallizer is plugged with asbestos thread and coated with graphite latex to prevent copper from seeping into the air.

[0046] The depth of the graphite mold inserted into the copper liquid is 50 mm, and the temperature difference between the inlet and outlet of the crystallizer cooling water is 15°C. The melting furnace temperature is 1205°C, the holding furnace temperature is 1155°C, the melting furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com