Flexible Production System for Grinding Inspection of Miniature Die Castings

A flexible production and die-casting technology, applied in the field of automation, can solve the problems of inappropriate micro-small die-casting grinding treatment, inappropriate micro-small die-casting production management, unfavorable system miniaturization and integration, etc., to achieve diversified production. , facilitate information query and technical support, improve the effect of production and labor environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

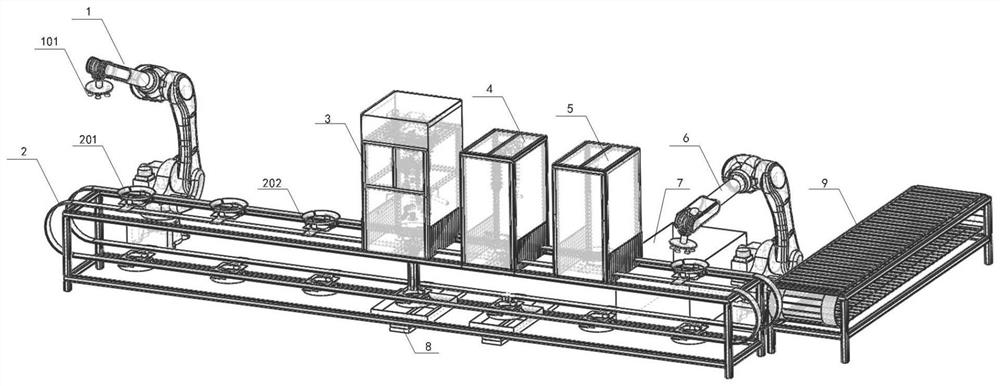

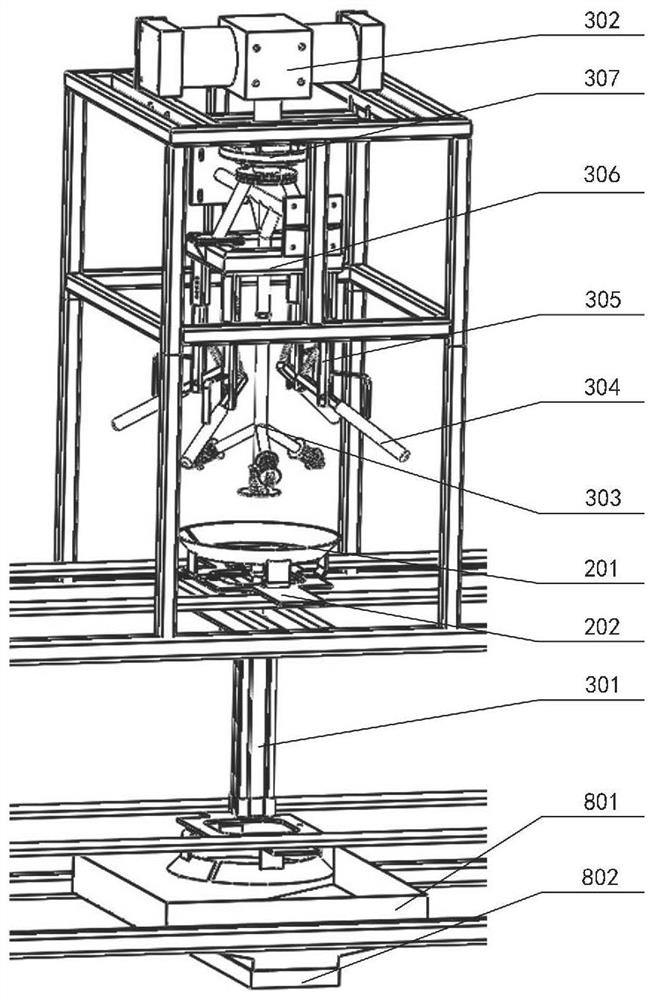

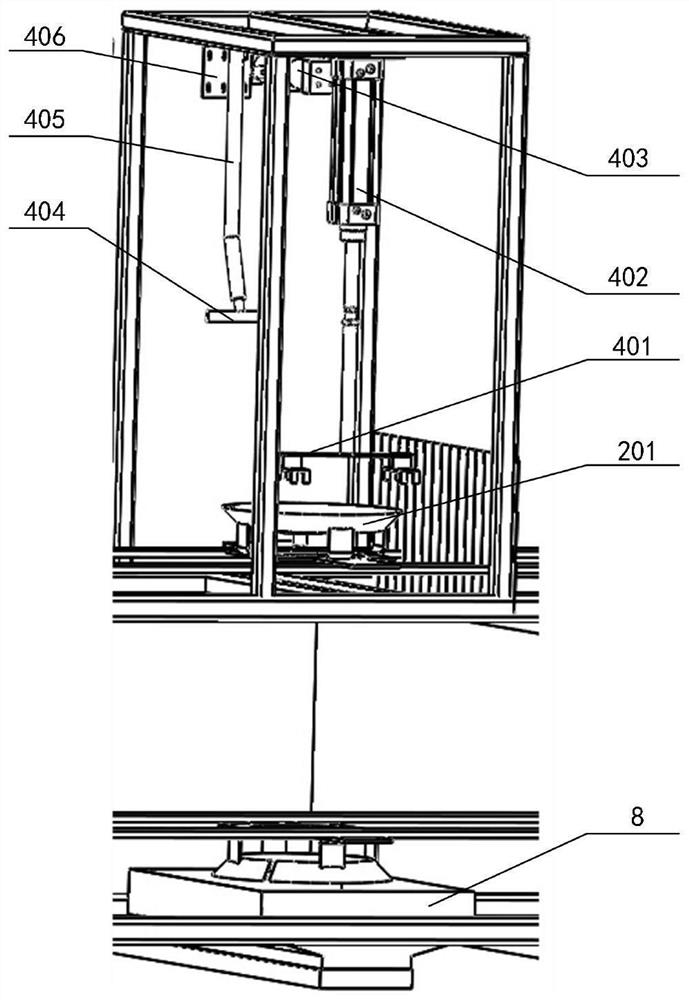

[0063] Such as figure 1 As shown, the present embodiment takes gray cast iron die-casting 320 type frying pan as an example for illustration. A flexible production line and management system for intelligent grinding and detection of miniature die-casting parts in this embodiment mainly includes a loading and unloading unit, a conveying unit, a grinding unit, a purging unit, a detection unit, a central processing and a control unit. The loading and unloading unit realizes the loading and unloading of the workpiece, the transfer unit realizes the intermittent movement of the workpiece at different processing stations, the grinding unit, the purging unit and the detection unit respectively realize the different process processing of the workpiece, and the central processing and control unit controls the rest of the units. Centralized management and scheduling to achieve flexible production of workpieces of different specifications and models.

[0064] Further, the loading and un...

Embodiment 2

[0071] Such as figure 1 As shown, this embodiment is described by taking a 28-type instrument disc-shaped housing die-cast from 6061 aluminum alloy as an example. A flexible production line and management system for intelligent grinding and detection of miniature die-casting parts in this embodiment mainly includes a loading and unloading unit, a conveying unit, a grinding unit, a purging unit, a detection unit, a central processing and a control unit. The loading and unloading unit realizes the loading and unloading of the workpiece, the transfer unit realizes the intermittent movement of the workpiece at different processing stations, the grinding unit, the purging unit and the detection unit respectively realize the different process processing of the workpiece, and the central processing and control unit controls the rest of the units. Centralized management and scheduling to achieve flexible production of workpieces of different specifications and models.

[0072] Furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com