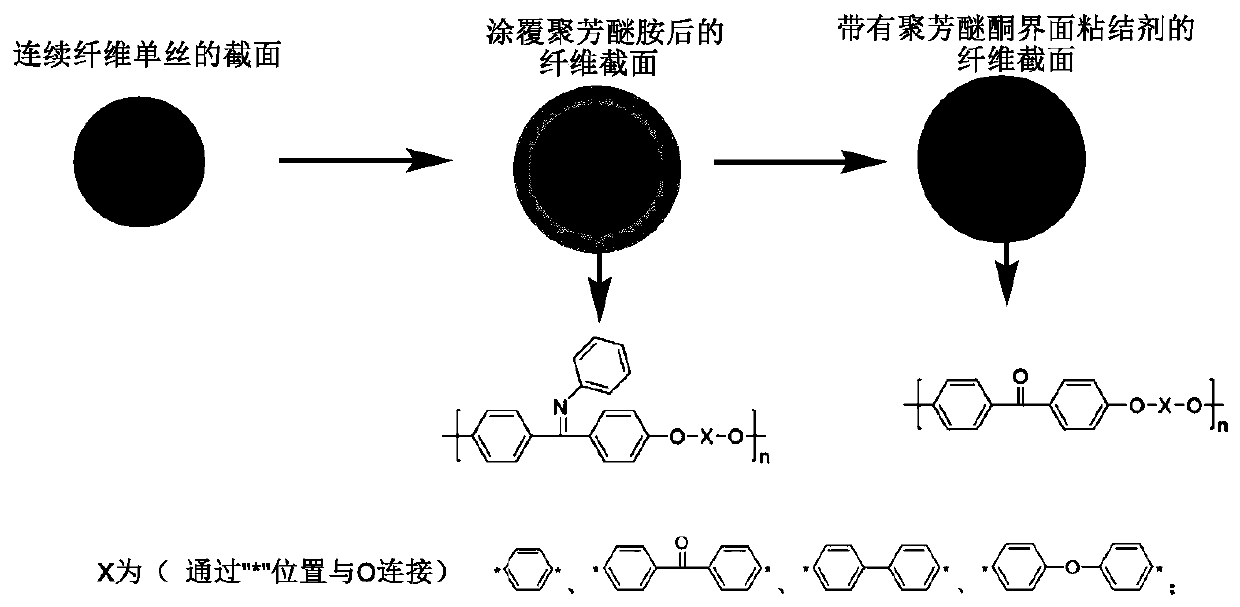

Continuous fiber-reinforced polyaryletherketone composite material and preparation method thereof

A polyaryletherketone and continuous fiber technology, which is applied in the field of continuous fiber reinforced polyaryletherketone composite material and its preparation, can solve the problems of enhanced interfacial adhesion, complicated preparation process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

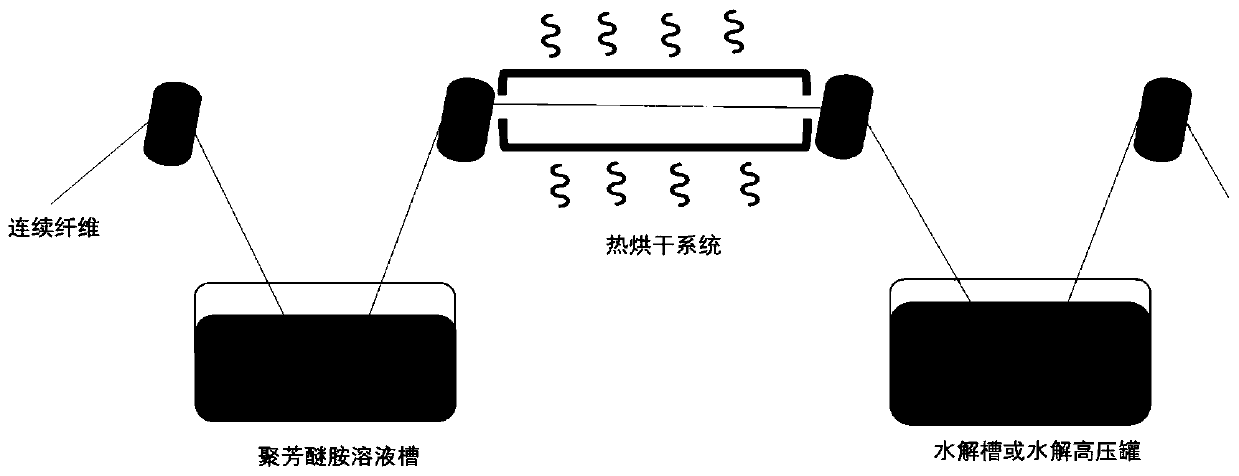

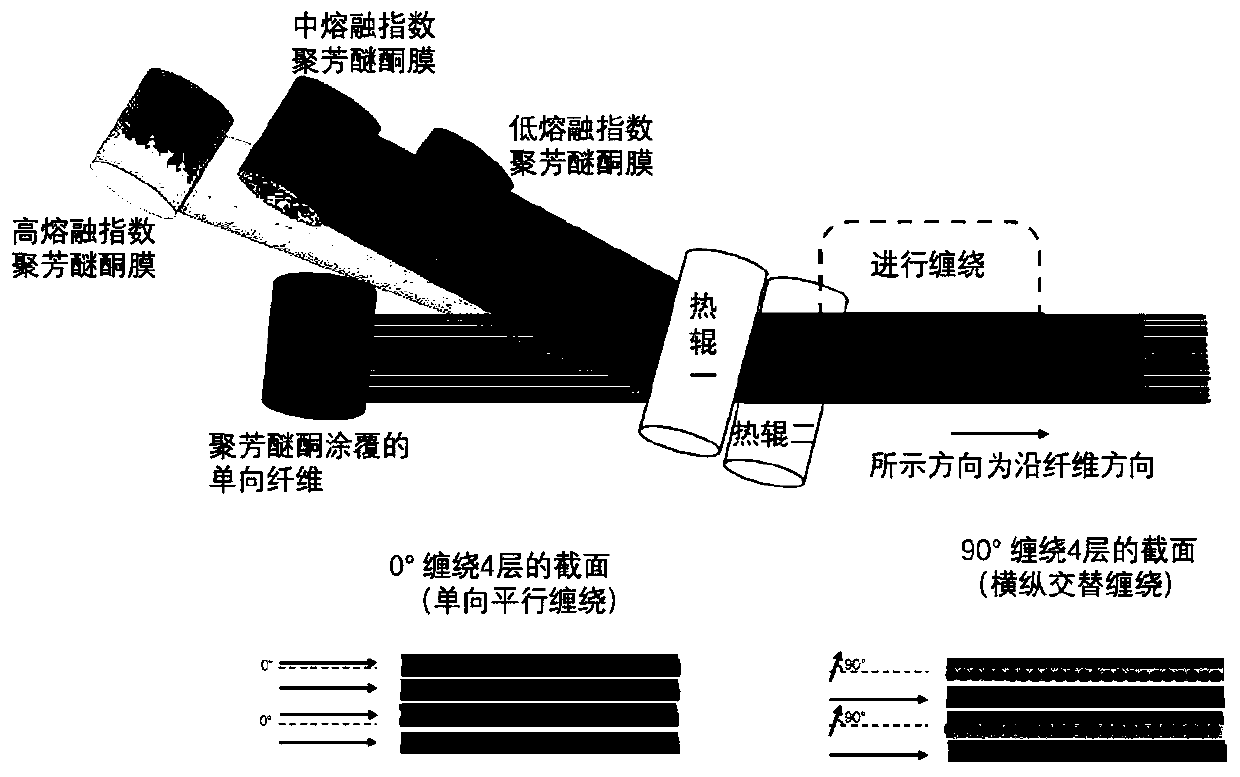

Method used

Image

Examples

Embodiment 1

[0025] Prepare 1000 mL of a DMF solution of polyetheretheramine with a mass percent concentration of 5%, place it in a fiber treatment solution tank, and keep the solution temperature at 40°C. The carbon fiber filament (T700) is pulled by the pulling roller at a line speed of 1m / min, and then immersed in the above polyetheretheramine DMF solution for coating; after heating and drying system, the drying temperature is 150°C, and the surface coating is obtained after winding. Continuous carbon fiber filament (L-CF-5) coated with polyetheretheramine. The amount of sizing on the fiber is calculated as 1.9% by mass weighing method.

Embodiment 2

[0027] The method described in Example 1 was changed to 1% by mass of the polymer solution to obtain a continuous carbon fiber (L-CF-0.1) coated with polyetheretheramine. Calculate fiber sizing amount 0.5wt% by mass weighing method.

Embodiment 3

[0029] The method described in Example 1 was changed to 20% by mass of the polymer solution to obtain a continuous carbon fiber (L-CF-20) coated with polyetheretheramine. The amount of fiber sizing was calculated to be 5.2wt% by mass weighing method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com