Barrier composite film and preparation method thereof

A composite film and adhesive technology, applied in the direction of film/sheet-like adhesives, adhesives, etc., can solve the problems of water vapor barrier effect, unsatisfactory peel strength and filling performance, complex process, etc., and achieve good sealing and barrier effect. , The process is simple, the effect of blocking water permeability is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

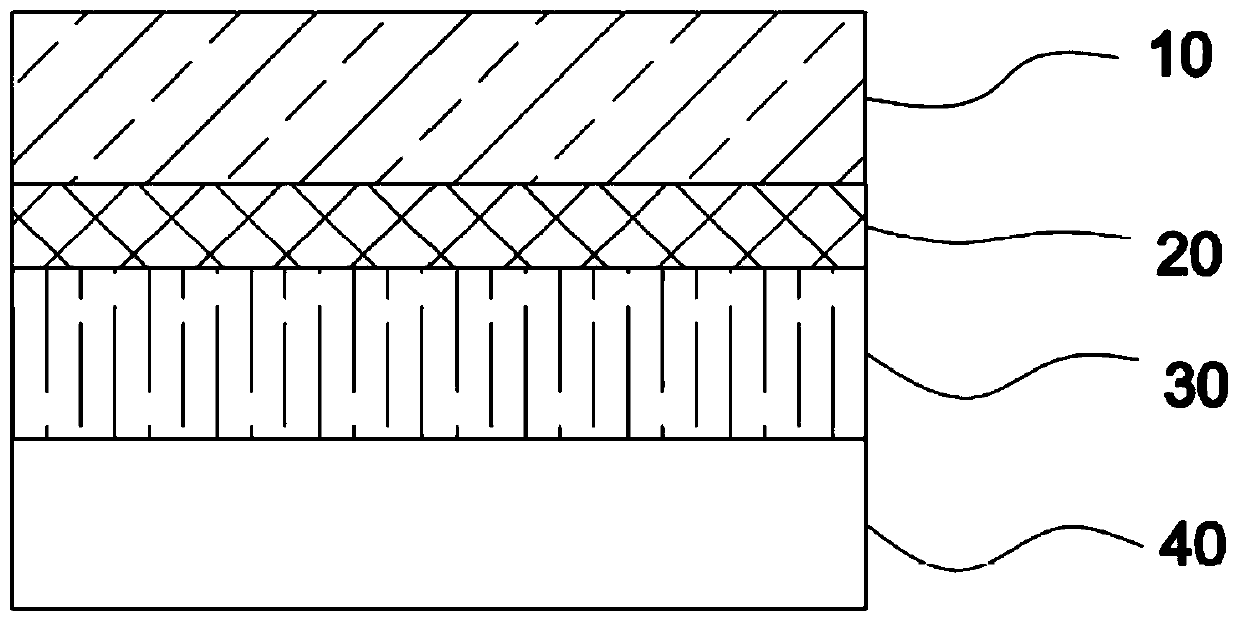

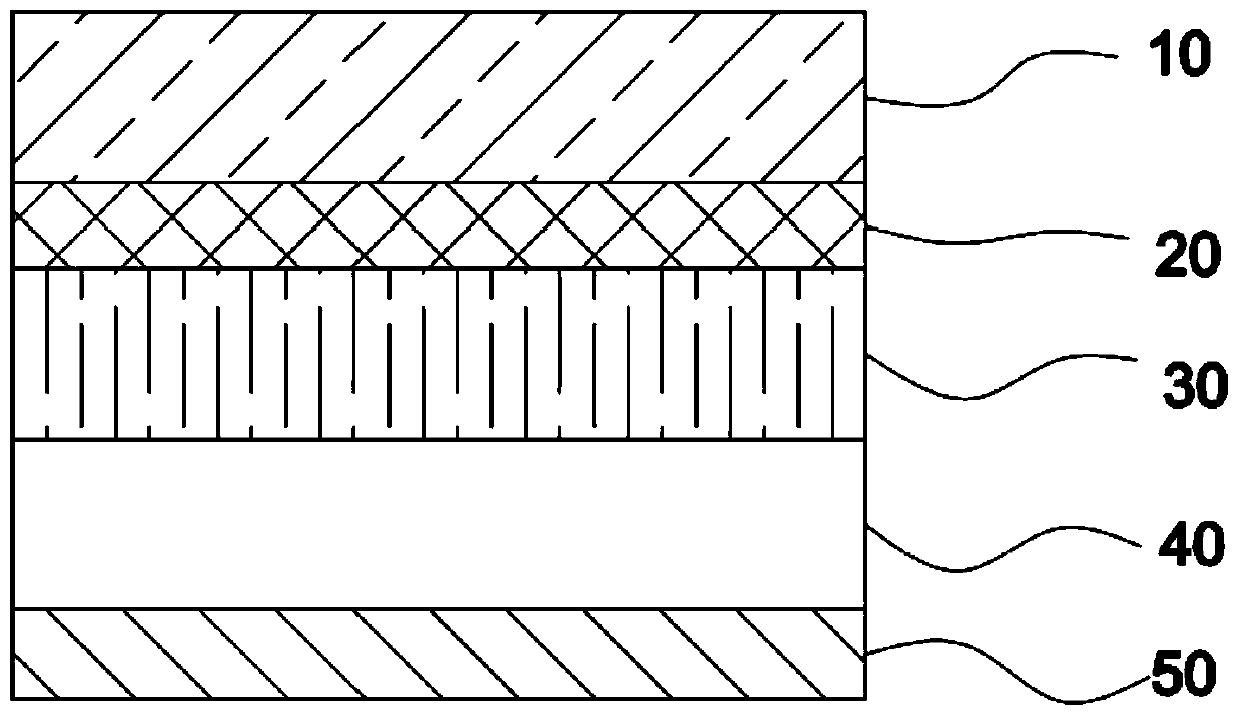

[0055] As one of the preferred embodiments of the present invention, the preparation method of the barrier film of the present invention includes: coating the first adhesive on the polymer layer 10 to form the first adhesive layer 20, and then laminating it with the metal layer 30 , and then coat or stick a layer of pressure-sensitive adhesive or thermosetting adhesive on the other side of the metal layer 30 to form the second adhesive layer 40 , and then stick to the release protection layer 50 .

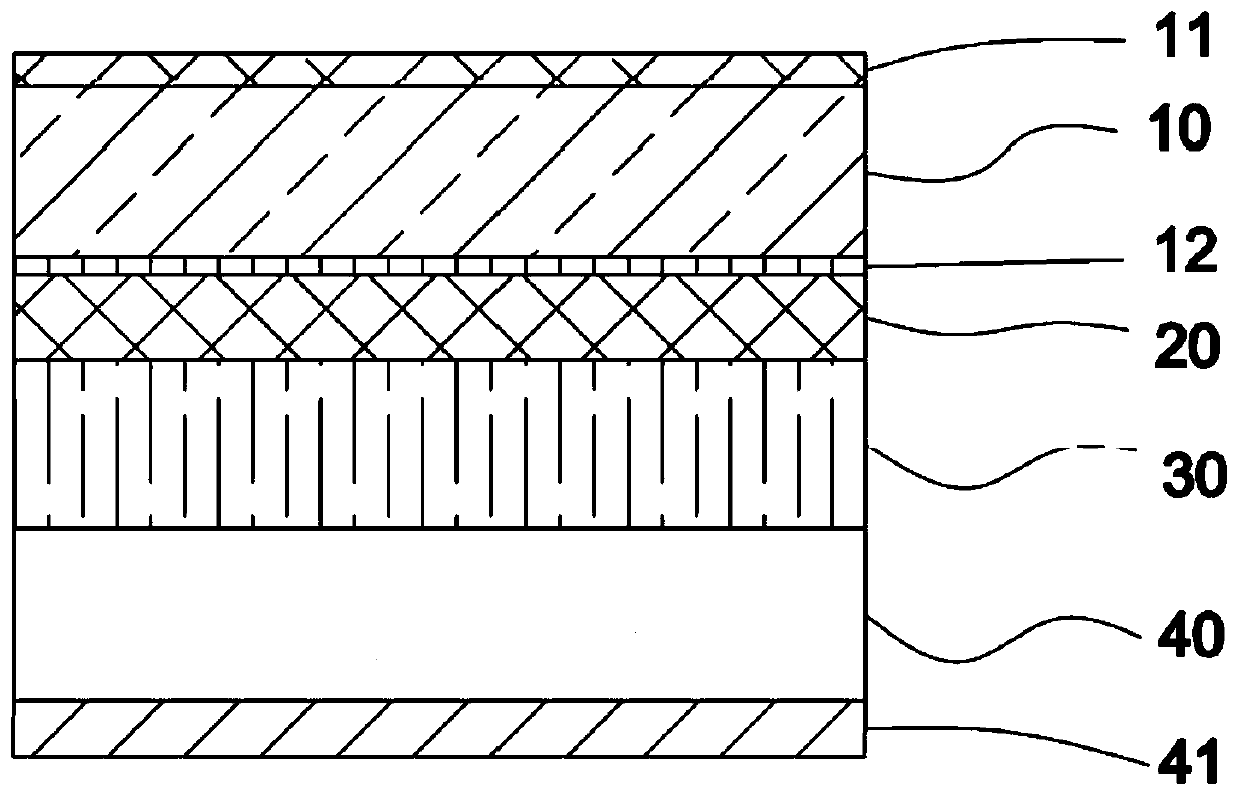

[0056] As one of the preferred embodiments of the present invention, before the step of applying the first adhesive layer 20 to the high molecular polymer layer 10, the high molecular polymer layer 10 is first subjected to inorganic treatment to form the inorganic layer 12, and / or hardening treatment to form the hardened protective layer 11 .

Embodiment 1

[0059] As shown in Table 1, use a 50 μm thick PET film (DuPont Hongji 50 μm) as the substrate layer, and coat a layer of 10 μm thick polyester adhesive (Comax D812) on the surface of the PET film as the first adhesive After that, it is laminated with a rolled copper foil with a thickness of 50 μm, and then coated with an acrylic adhesive (DIC 6030) with a thickness of 50 μm on the other side of the copper foil. The properties of the barrier film are shown in Table 2.

Embodiment 2

[0061] As in the composite barrier film provided in Example 1, the difference lies in that the thickness of the copper foil is 10 μm, and the properties of the barrier film are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com