Non-ferrous metallurgy unit process digitization and modeling method based on process state space

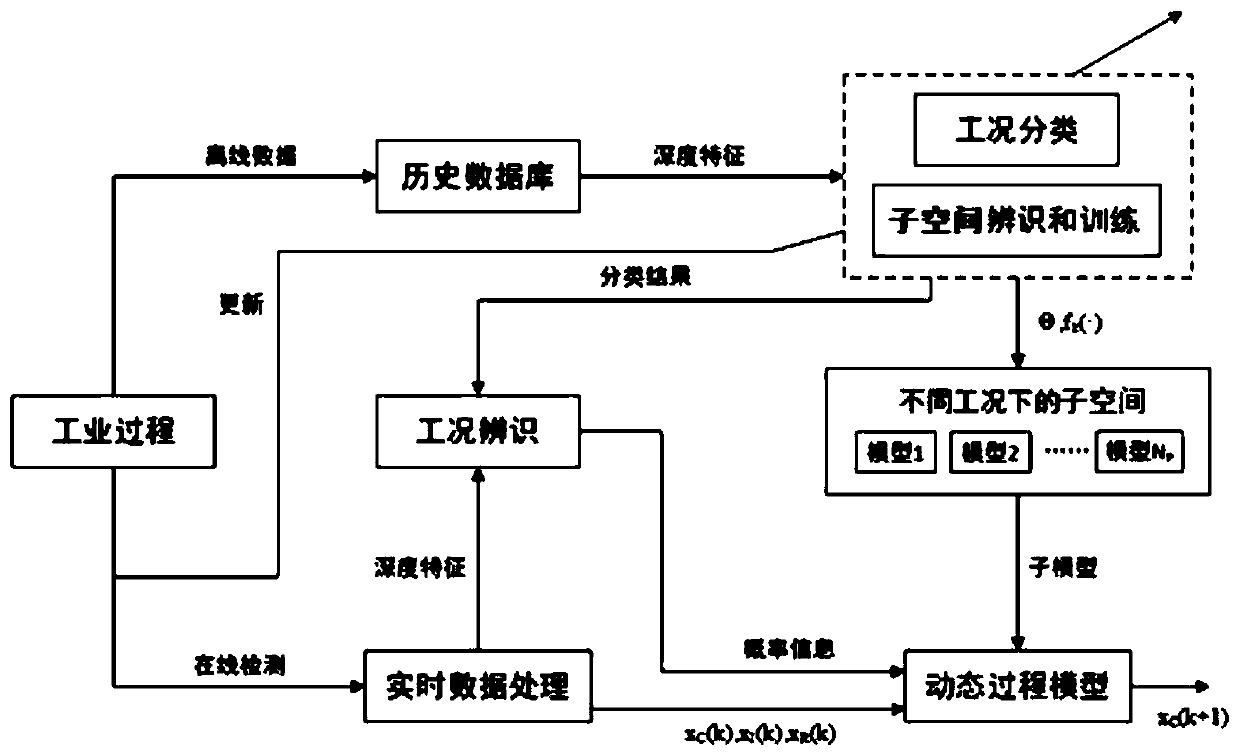

A process state and modeling method technology, applied in the direction of electrical digital data processing, comprehensive factory control, process efficiency improvement, etc., can solve the problems of data-driven modeling method performance impact, can not be covered, etc., to improve control performance, high The effect of information utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

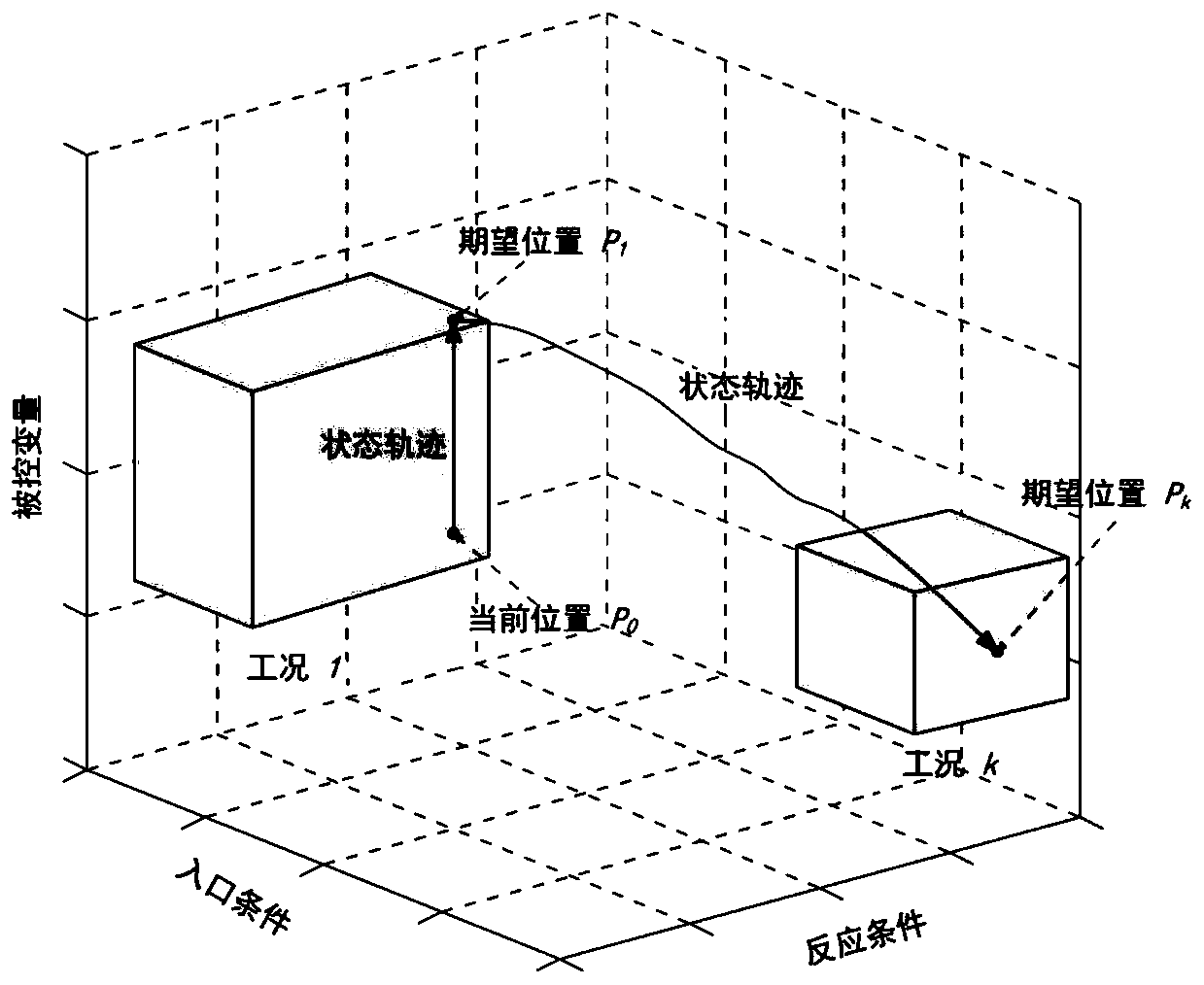

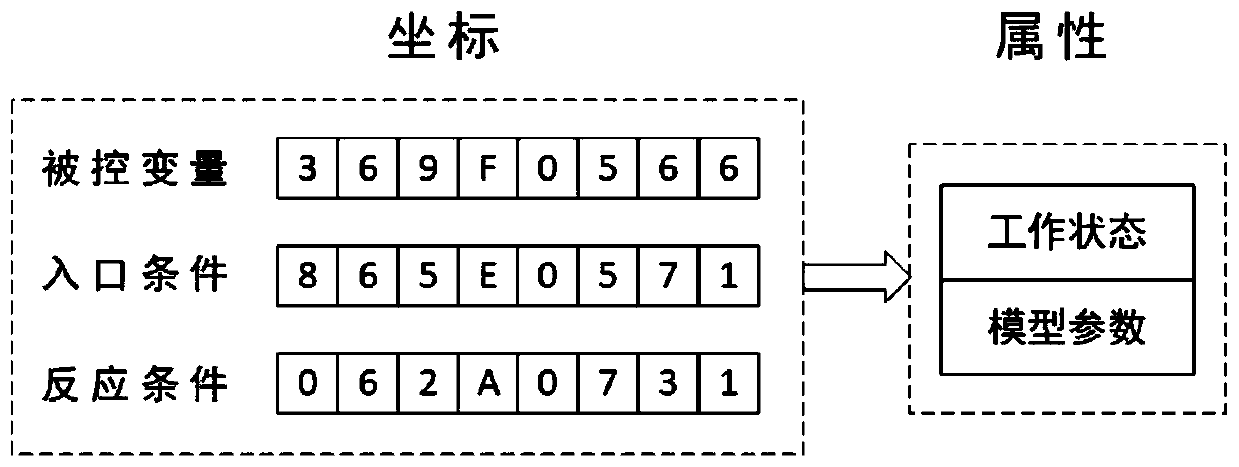

[0120] The non-ferrous metallurgy unit process digitization and modeling method based on the process state space provided by this embodiment takes the cobalt removal process of hydrometallurgy as the object, establishes a comprehensive and accurate description system for the cobalt removal process, constructs a three-dimensional process state space, and realizes cobalt removal Process digitization.

[0121] Figure 6 It is a schematic diagram of the cobalt removal process. The basic principle of cobalt removal is to replace the cobalt ions in the solution by adding zinc powder. However, this replacement process is extremely complicated. In addition to the main reactions, there are many side reactions in addition to the cobalt process. The flow rate of inlet solution, waste acid, arsenic salt, underflow, and the interaction between the cobalt removal process and its upstream and downstream processes will all affect its dynamic characteristics.

[0122] Firstly, the nominal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com