Preparation method of a personalized 3D printed tibial high osteotomy guide plate

A 3D printing and osteotomy technology, applied in bone drill guidance, medical science, surgery, etc., can solve problems such as difficult to ensure the accuracy of osteotomy position, increase the risk of postoperative infection of patients, and easily endanger the health of surgeons, etc., to achieve The effect of precision medicine and personalized treatment, shortening the time of surgical anesthesia, and shortening the operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

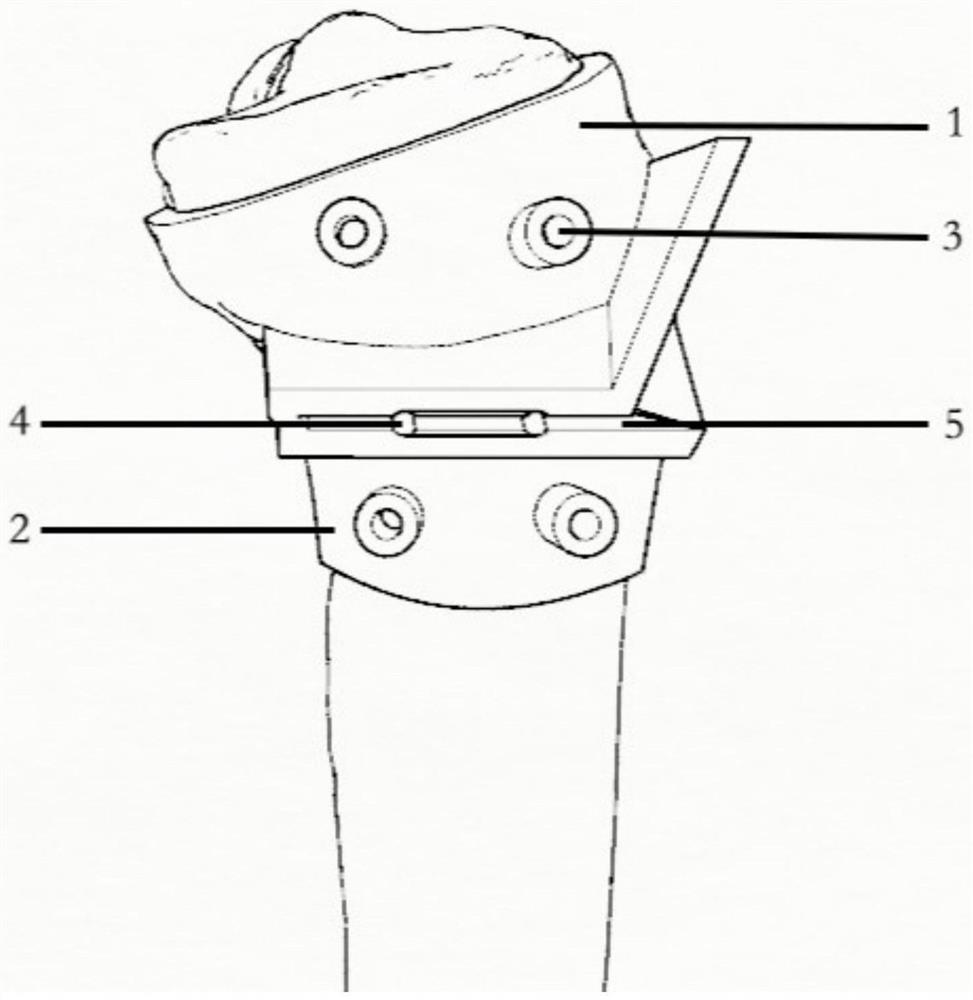

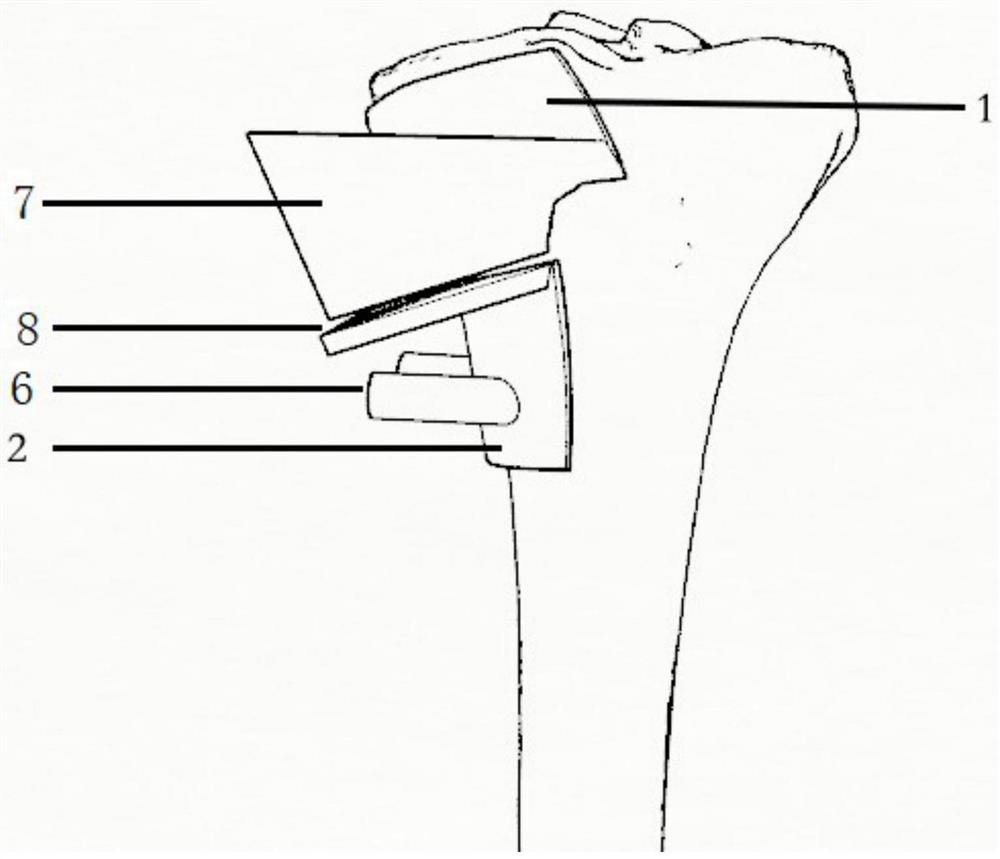

[0027] The technical solution of the present invention will be described in further detail below in conjunction with the embodiments.

[0028] A method for preparing a personalized 3D printed tibial high osteotomy guide plate, comprising the following steps:

[0029] Step 1. All patients were treated with 64-slice spiral CT with a slice thickness of 0.8mm and a slice interval of 0.5mm. The scanned images were saved in dicom format; the 3D image restoration software mimics19.0 was used to restore the dicom format data in 3D, and the threshold technology was used for preliminary processing , and then use filling technology to repair the gap holes generated by data conversion; get 3D data and transfer it to 3matic in stl format;

[0030] Step 2. Use BOHOLO software to restore the dicom format data for the second time, use the same threshold as step 1 for preliminary processing, and use 3D filling technology to repair the gaps generated by data conversion, obtain 3D data, and expo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com