A full-range coal tar processing process

A processing technology and technology of coal tar, applied in the field of coal chemical industry, can solve the problems of high yield of wax oil, low naphtha and diesel oil, etc., and achieve the effect of solving short operation period and avoiding excessive cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

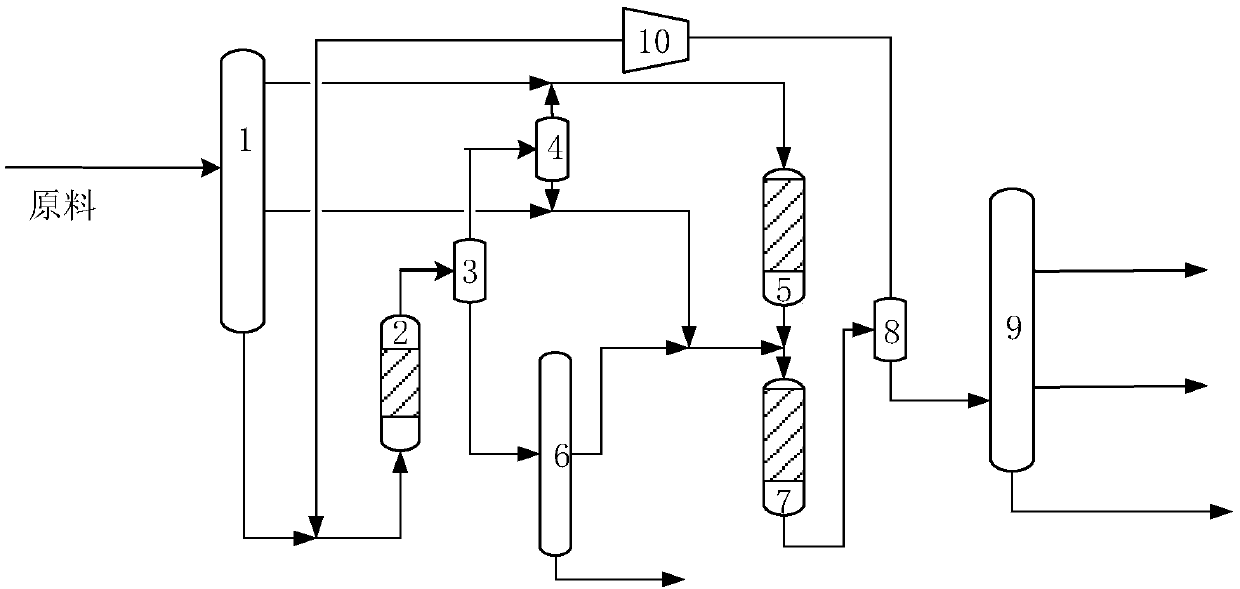

[0039] The present embodiment provides a kind of processing technology of whole distillate coal tar, such as figure 1 shown, including the following steps:

[0040] 1) Pass the full fraction coal tar into the full fraction coal tar fractionation tower 1, and conduct the first fractionation on the full fraction coal tar at normal pressure and 265° C. to obtain light coal tar with a distillation range of 60-180° C. , Medium coal tar with a distillation range of 180-230°C and heavy coal tar with a distillation range of 230-800°C;

[0041] 2) Pass the heavy coal tar into the suspension bed hydrogenation reactor 2, and react at a reaction pressure of 20Mpa, a reaction temperature of 410°C, for 0.3h -1 Under the space velocity of 1300:1 hydrogen-oil volume ratio, carry out first hydrogenation to described heavy coal tar sequentially, hydrogenation catalyst is powdery amorphous iron oxyhydroxide, and addition is 1.5wt%; And The hydrogenated product is passed into the product separa...

Embodiment 2

[0047] The present embodiment provides a kind of processing technology of whole cut coal tar, comprises the steps:

[0048] 1) Pass the full fraction coal tar into the full fraction coal tar fractionation tower 1, and conduct the first fractionation on the full fraction coal tar at normal pressure and 250°C to obtain light coal tar with a distillation range of 60-180°C , Medium coal tar with a distillation range of 180-230°C and heavy coal tar with a distillation range of 230-800°C;

[0049] 2) Pass the heavy coal tar into the suspension bed hydrogenation reactor 2, and react at a reaction pressure of 18Mpa, a reaction temperature of 450°C, and 0.1h -1 Under the space velocity of 1500:1 and the hydrogen-oil volume ratio, carry out first hydrogenation to described heavy coal tar successively, hydrogenation catalyst is powdery magnetic iron oxide, and addition amount is 2wt%; And after hydrogenation The product is passed into the product separation device 3 for separation, and ...

Embodiment 3

[0055] The present embodiment provides a kind of processing technology of whole cut coal tar, comprises the steps:

[0056] 1) Pass the full fraction coal tar into the full fraction coal tar fractionation tower 1, and conduct the first fractionation on the full fraction coal tar at normal pressure and 280°C to obtain light coal tar with a distillation range of 60-180°C , Medium coal tar with a distillation range of 180-230°C and heavy coal tar with a distillation range of 230-800°C;

[0057] 2) Pass the heavy coal tar into the suspension bed hydrogenation reactor 2, and react at a reaction pressure of 22Mpa, a reaction temperature of 380°C, and 0.5h -1 Under the space velocity of 1000:1 hydrogen-oil volume ratio, carry out first hydrogenation to described heavy coal tar sequentially, hydrogenation catalyst is powdery α-iron oxyhydroxide, and addition is 0.5wt%; And The hydrogenated product is passed into the product separation device 3 for separation, and the separation param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com