Metal component hole wall surface nanocrystallization device

A metal component and nano-technology, which is applied in the field of metal surface engineering, can solve problems such as large pore size restrictions, and achieve the effects of simple installation method, simple production and strong versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

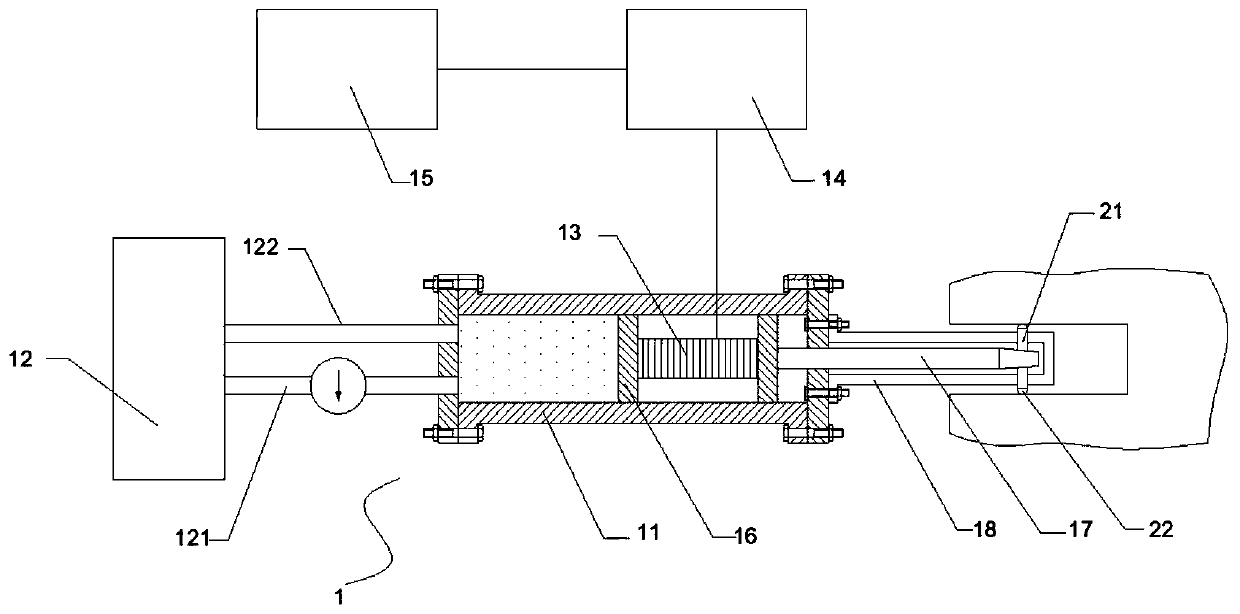

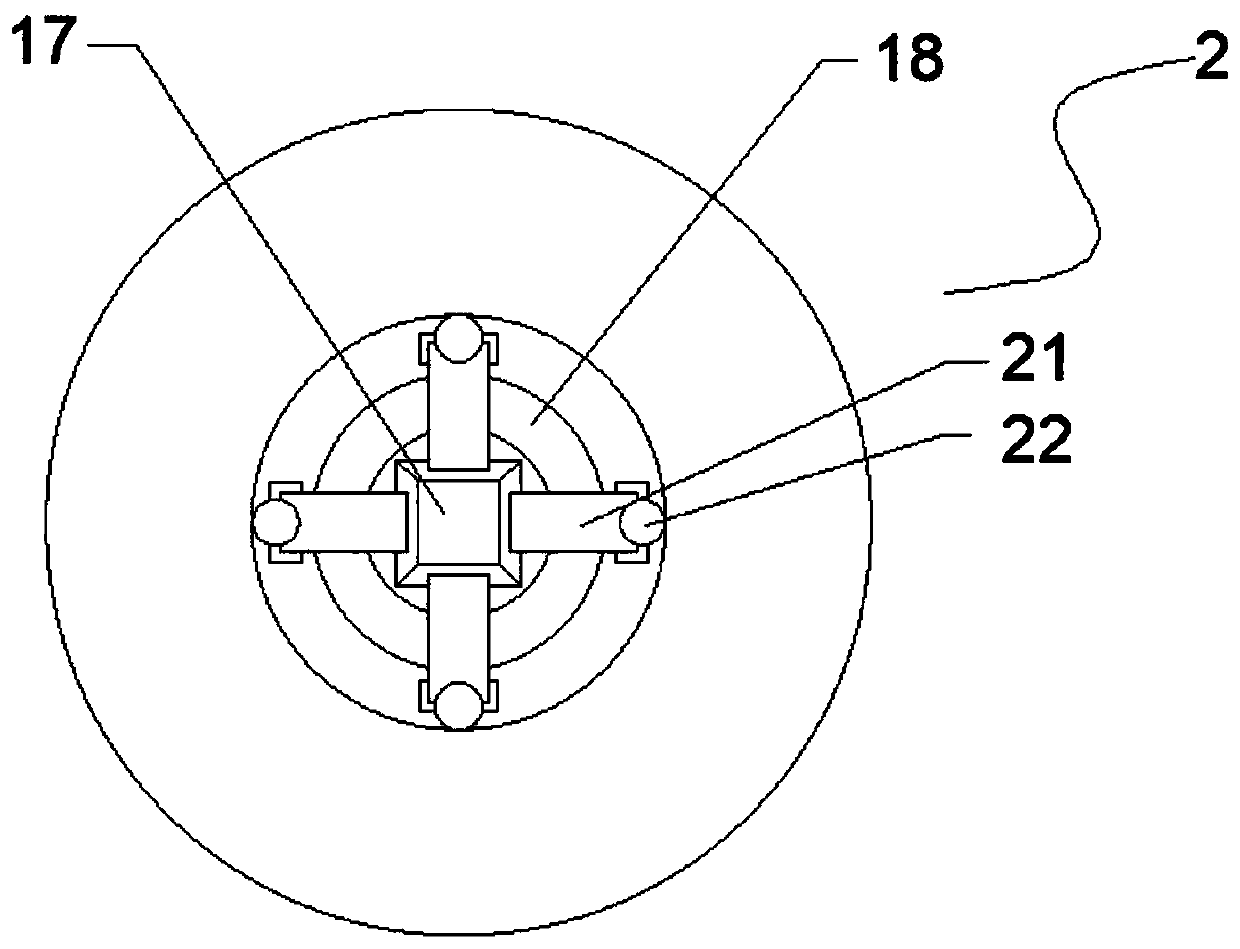

[0023] Such as figure 1 , figure 2 A nanometerization device for the surface of a metal member hole wall is shown, including an ultrasonic transducer system 1 and a metal member hole wall striker 2; the ultrasonic transducer system 1 is drivingly connected to the metal member hole wall striker 2 for driving the metal member The hole wall striker 2 moves relative to the hole wall of the metal component to be nano-processed.

[0024] The ultrasonic transducer system 1 includes an oil cylinder 11, a hydraulic pump 12, a piezoelectric ceramic stack 13, a power amplifier 14 and a signal generator 15; a piston 16 is arranged in the oil cylinder 11; the output end of the hydraulic pump 12 is provided with a liquid outlet pipeline 121 and The liquid return pipeline 122 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com