Copper-iron alloy wire rod and preparation method thereof

A copper-iron alloy and wire technology, applied in the field of copper-iron alloy wire and its preparation, can solve the problems of difficulty in the production and application of Cu-Fe alloy, easy macrosegregation of alloys, unsatisfactory preparation difficulties, etc., so as to reduce the risk of impurity introduction, The effect of dense organization and prevention of calendering cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A copper-iron alloy wire with a diameter of 3mm and a 10% iron content, and its chemical composition is shown in Table 1.

[0054] The method for preparing the copper-iron alloy wire includes the following steps:

[0055] 1) Batching and smelting: raw materials are electrolytic copper and industrial pure iron, which are batched according to the chemical composition of the copper-iron alloy wire. The furnace is loaded and vacuumed and then melted. The vacuum is ≤10Pa, the melting temperature is 1350℃, and the material is completely melted and kept for 30 minutes;

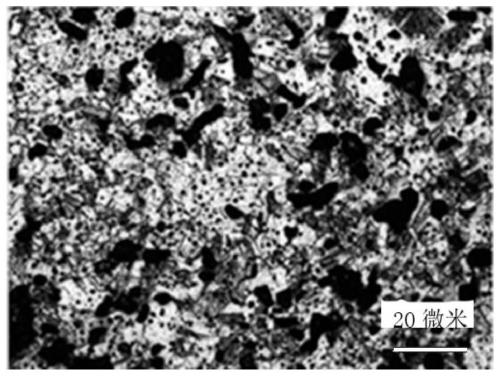

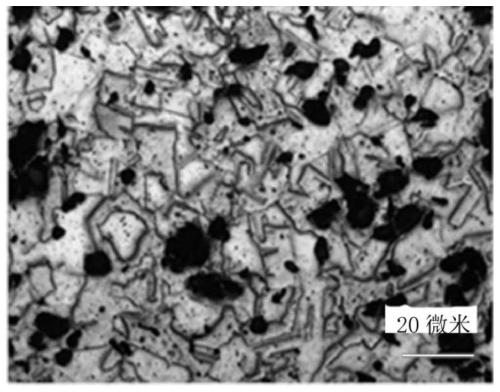

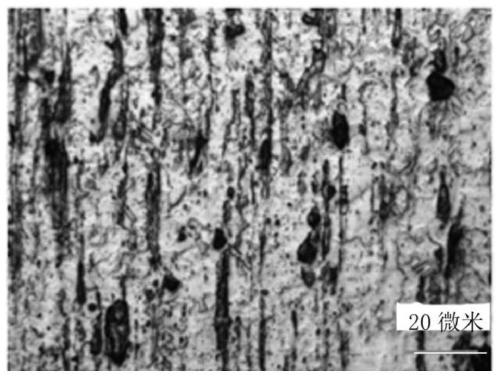

[0056] 2) Casting: Cast the molten copper-iron alloy liquid onto the surface of the copper roller, the speed of the copper roller is 40r / min, the linear velocity of the outer edge is 2m / s, the copper roller is cooled with circulating cooling water, and the water pressure of the circulating cooling water is 0.6 MPa, the water outlet temperature is 35℃, the copper-iron alloy thin strip blank is produced, and the thickn...

Embodiment 2

[0064] A copper-iron alloy wire with a diameter of 3mm and a 30% iron content. Its chemical composition is shown in Table 1.

[0065] The method for preparing the copper-iron alloy wire includes the following steps:

[0066] 1) Batching and smelting: raw materials are electrolytic copper and industrial pure iron, which are batched according to the chemical composition of the copper-iron alloy wire. The furnace is loaded and vacuumed and then melted. The vacuum is ≤10Pa, the melting temperature is 1420℃, and the material is completely melted and kept for 40min;

[0067] 2) Casting: Cast the molten copper-iron alloy liquid onto the surface of the copper roller, the speed of the copper roller is 40r / min, the linear velocity of the outer edge is 2m / s, the copper roller is cooled with circulating cooling water, and the water pressure of the circulating cooling water is 0.6 MPa, the water outlet temperature is 38℃, the copper-iron alloy thin strip blank is produced, and the thickness of th...

Embodiment 3

[0075] A copper-iron alloy wire with a diameter of 1.6mm and a 15% iron content. Its chemical composition is shown in Table 1.

[0076] The method for preparing the above copper-iron alloy wire includes the following steps:

[0077] 1) Batching and smelting: raw materials are electrolytic copper and industrial pure iron, which are batched according to the chemical composition of the copper-iron alloy wire. The furnace is installed and vacuumed and then melted. The vacuum is ≤10Pa, the melting temperature is 1380℃, and the material is completely melted and kept for 30min;

[0078] 2) Casting: Cast the molten copper-iron alloy liquid onto the surface of the copper roller, the speed of the copper roller is 40r / min, the linear velocity of the outer edge is 2m / s, the copper roller is cooled with circulating cooling water, and the water pressure of the circulating cooling water is 0.6 MPa, the water outlet temperature is 36℃, the copper-iron alloy thin strip blank is produced, and the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com