Drilled hole opening mixed dedusting and noise reduction device, drilling equipment and working method

A hybrid, noise-reducing technology, applied to drilling equipment, drilling tools, earthwork drilling, etc., can solve problems such as the limitation of the spraying dust reduction effect of the spray head, the inability to adjust the water spray volume of the spray head, and the lack of noise treatment measures, etc., to achieve Ensure personal health, improve dust removal effect, and reduce construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

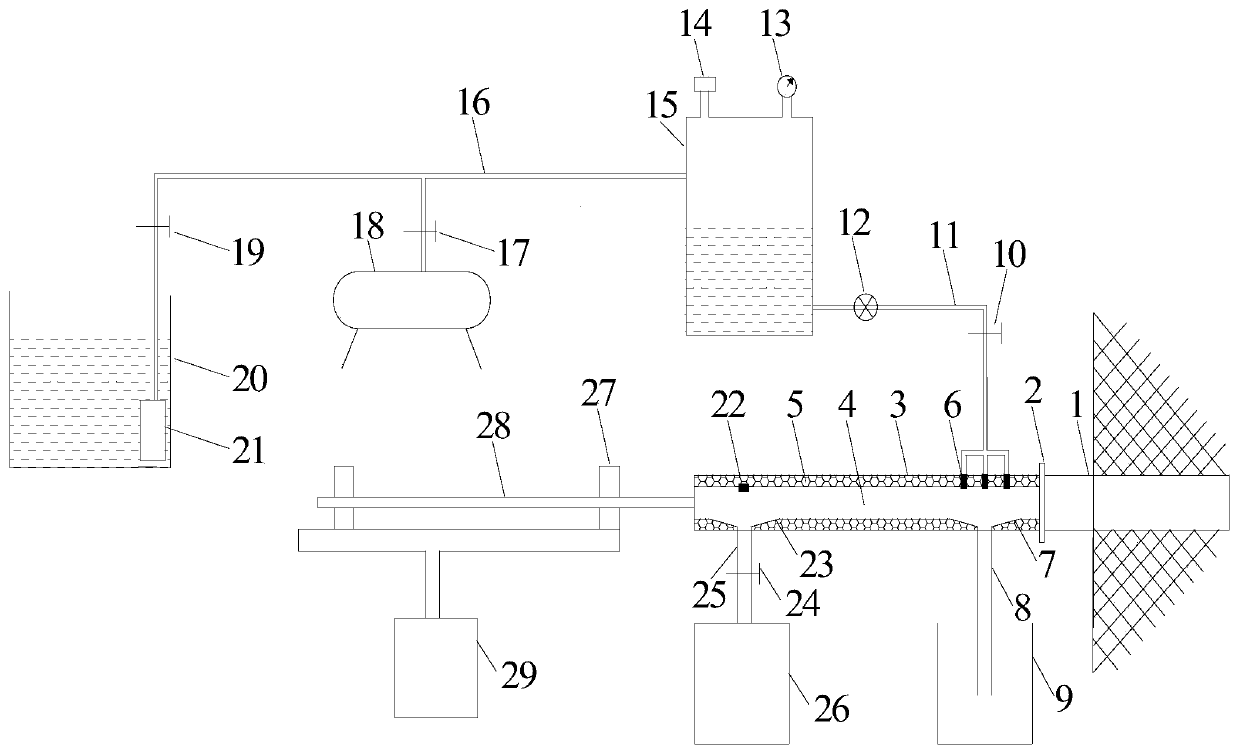

[0053] Attached below figure 1 The dust and noise reduction device disclosed in this embodiment will be further described;

[0054] Refer to attached figure 1 As shown, the drilling orifice hybrid dust removal and noise reduction device mainly consists of orifice pipe 1, flange plate 2, outer pipe 3, special-shaped inner pipe 4, wave peak sound-absorbing cotton 5, spray nozzle 6, water collecting funnel 7, sewage Pipe 8, sewage tank 9, flow control valve 10, water spray pipe 11, flow meter 12, pressure gauge 13, pressure switch 14, automatic water supply device 15, input pipe 16, air supply valve 17, air compressor 18, check Valve 19, water tank 20, clean water pump 21, dust suction port 22, dust suction funnel 23, control valve 24, dust suction pipe 25, vacuum cleaner 26 form.

[0055] The outer tube 3 and the special-shaped inner tube 4 constitute a dust removal and noise reduction pipeline. The special-shaped inner tube 4 is nested inside the outer tube 3, and a sound-abs...

Embodiment approach

[0066] The implementation method of the hybrid dust removal and noise reduction device of the present disclosure includes the following steps:

[0067] A. Using the process of oxygen acetylene gas cutting, three round holes with a diameter of 25mm are opened in the upper right part of the DN110 steel pipe at intervals, and the water collecting funnel 7 with a welding depth of 10mm is processed in the corresponding lower right part, and the diameter of the lower end of the water collecting funnel 7 is A circular hole with a diameter of 50mm is opened on the upper left part of the DN110 steel pipe to form a dust suction port 22, and a dust suction funnel 23 with a welding depth of 10mm is processed in the corresponding lower left area, and the diameter of the lower end of the dust suction funnel 23 is 50mm. Constitute a special-shaped inner tube 4;

[0068] B. Tightly wrap the peak sound-absorbing cotton 5 on the outside of the special-shaped inner tube 4, corresponding to the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com