Construction method of reinforced concrete liner composite lining structural form of shield tunnel

A reinforced concrete and composite lining technology, which is applied in the field of infrastructure engineering, can solve the problems of affecting water flow conditions, complex process, high cost, etc., and achieve the effects of improving bending stiffness, clear structure type, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments of the description.

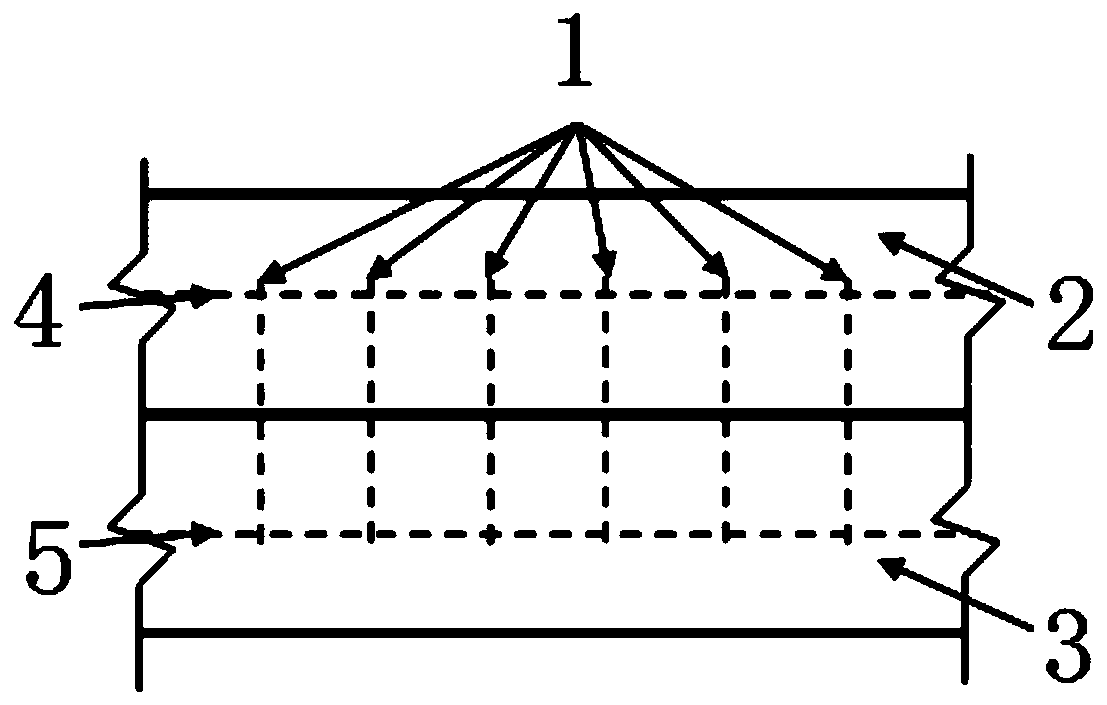

[0035] An embodiment of the present invention provides a method for constructing a reinforced concrete lining composite lining structure of a shield tunnel, including the following steps:

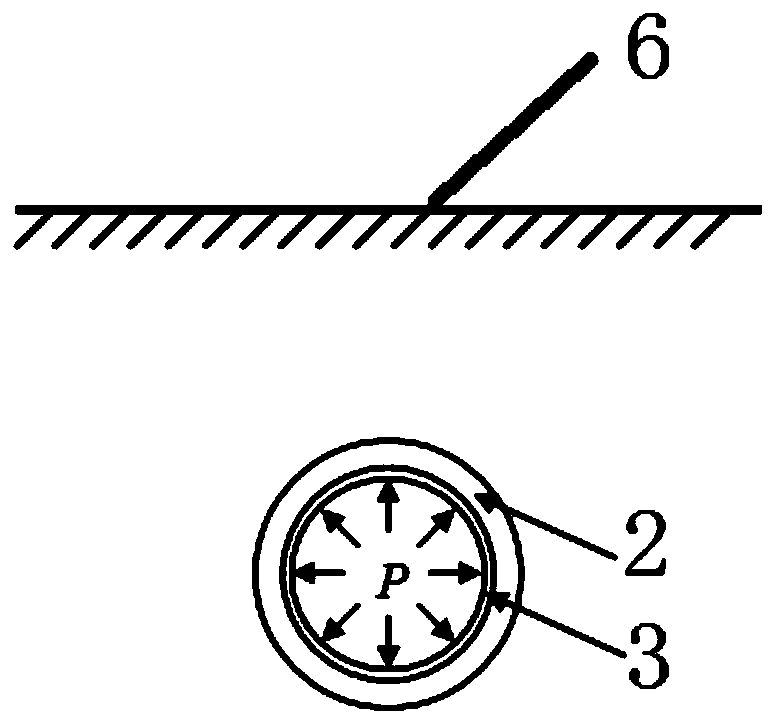

[0036] Reinforcement treatment is carried out on the shield segment, or the connection reinforcement position is reserved in the shield segment;

[0037] Bind or weld the connecting steel bar and the steel cage lined with reinforced concrete to form a shear bond;

[0038] Formwork the reinforcement cage and pour concrete to form a reinforced concrete lining;

[0039] Construction of shield-concrete-lined composite structure through shear bonds.

[0040] Further as a preferred embodiment, it also includes the following steps:

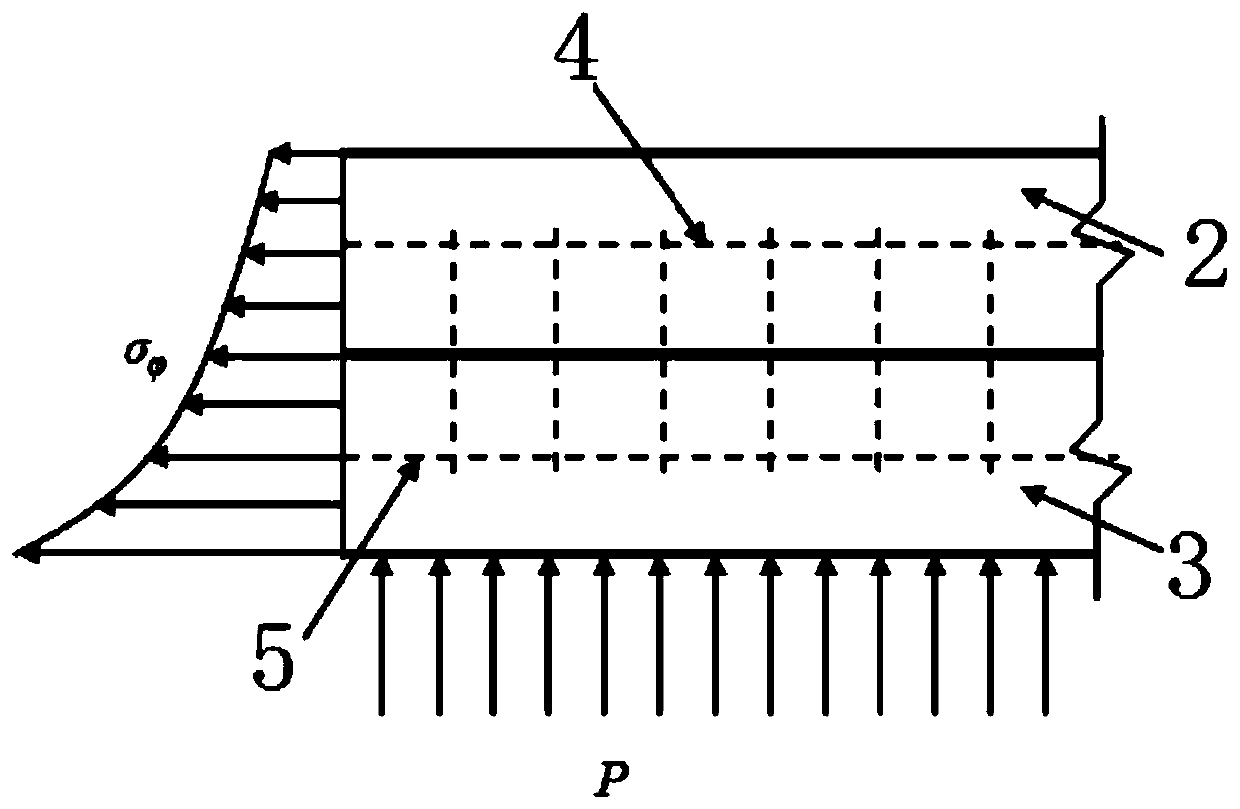

[0041] The internal water pressure and external water and soil pressure of the shield-concrete-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com