Pole piece containing solid electrolyte and preparation method and application thereof

A solid-state electrolyte and pole piece technology, which is applied in electrode manufacturing, electrolyte layer coating, non-aqueous electrolyte battery, etc., can solve the problems of hindering lithium ion shuttle, reducing battery chemical performance, poor lithium conduction performance, etc., to achieve energy density improvement, The effect of improving battery performance and improving lithium-conducting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

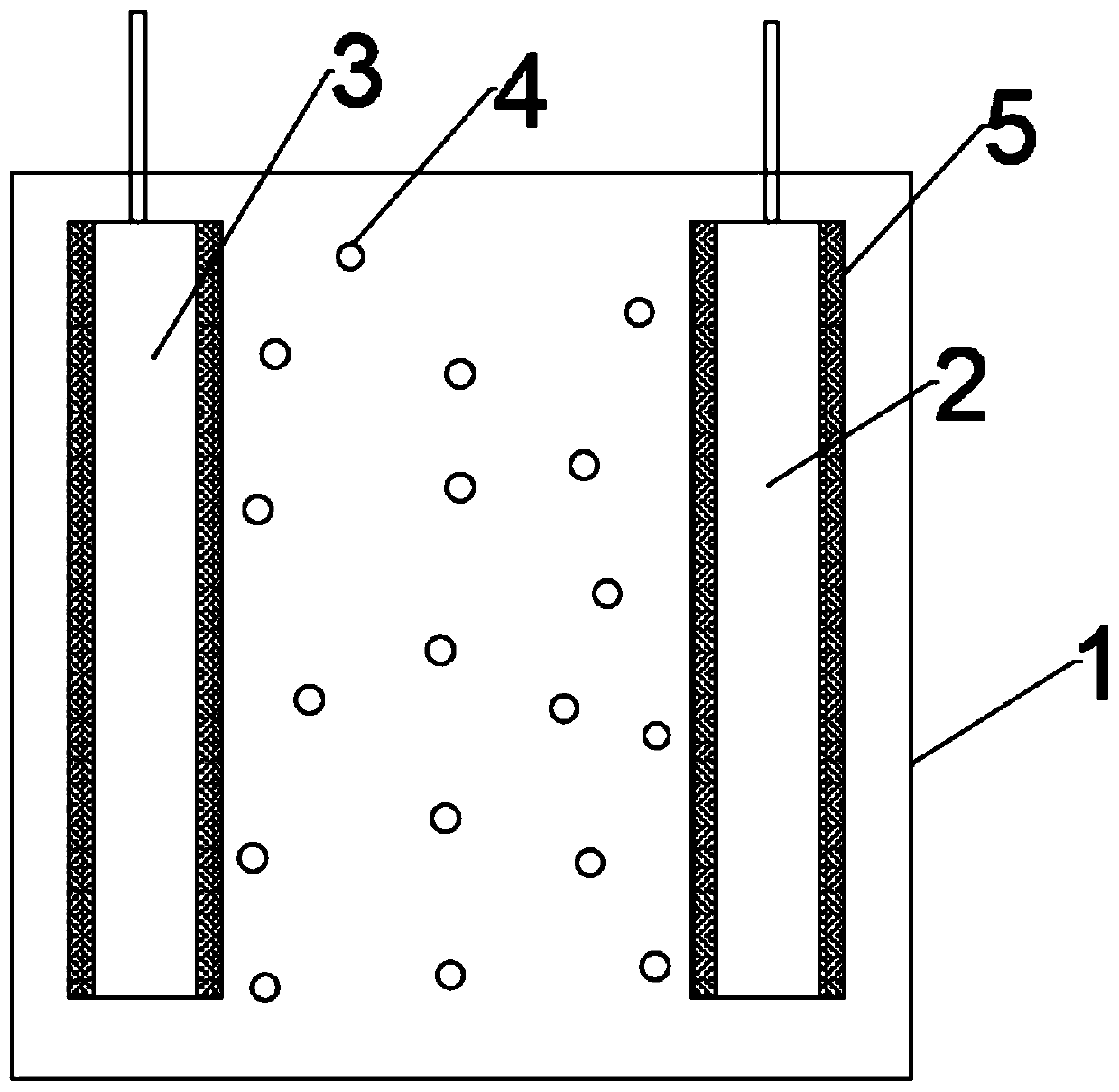

[0027] A pole piece containing a solid electrolyte includes a pole piece body and a solid electrolyte coating 5 coated on one or both sides of the pole piece body, and the thickness of the solid electrolyte coating 5 is 5 μm;

[0028] The solid electrolyte coating 5 includes the following raw materials, calculated in parts by weight, 0.5 parts of a dispersant, 10 parts of a solid electrolyte, 1 part of a binder, and 100 parts of a solvent.

[0029] The pole piece body includes a positive pole piece 2 and a negative pole piece 3 .

[0030] A method for preparing a pole piece containing a solid electrolyte, comprising the following steps:

[0031] S1: first disperse the dispersant into solvent A to obtain a dispersion solution, then spray the dispersion solution into a container with a solid electrolyte through an atomizing nozzle, and stir for 1 hour at the same time, the stirring speed is 800r / min, and the preparation get dispersion slurry;

[0032] S2: dissolving the binder...

Embodiment 2

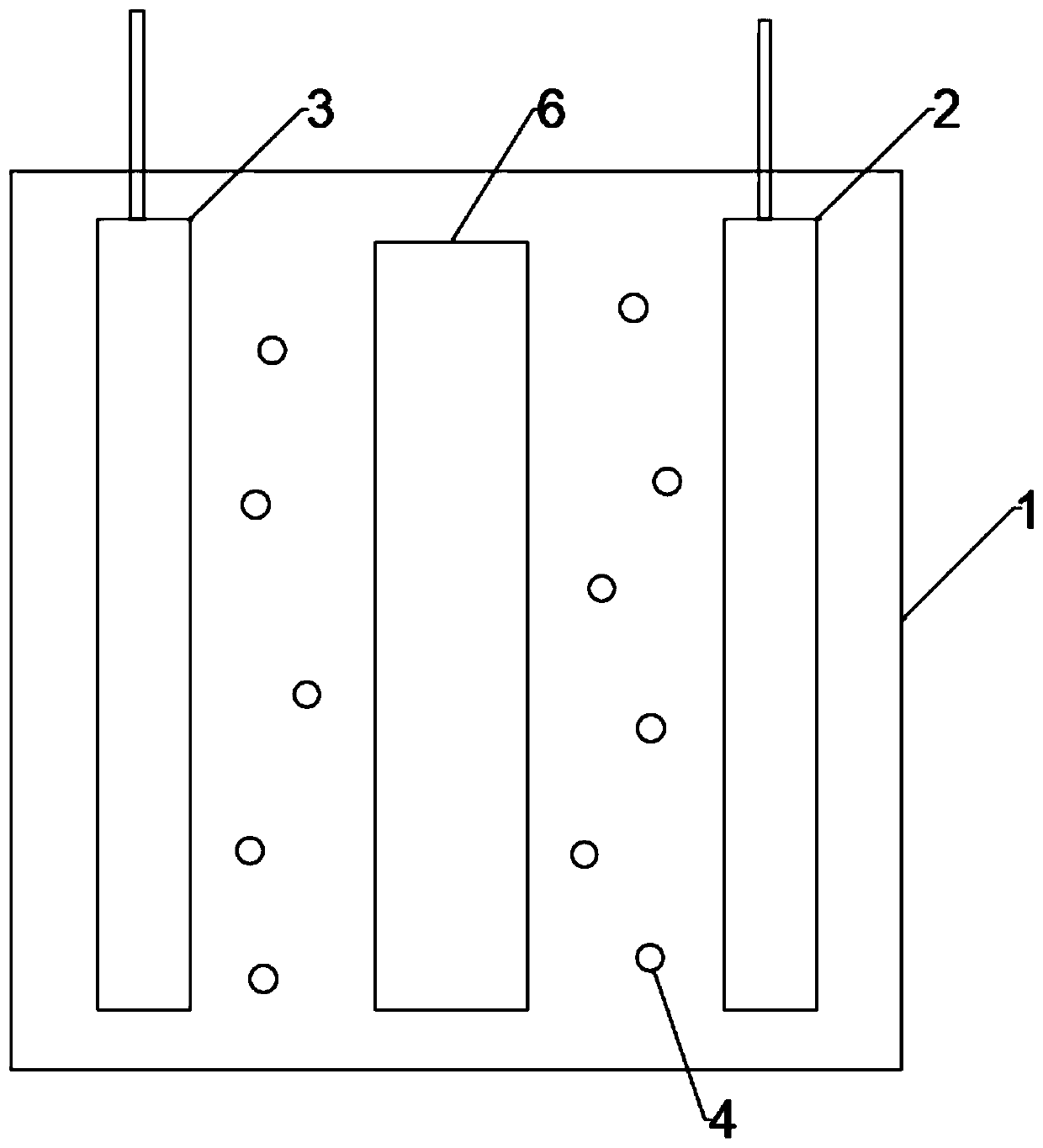

[0045] A pole piece containing a solid electrolyte includes a pole piece body and a solid electrolyte coating 5 coated on both sides of the pole piece body, and the thickness of the solid electrolyte coating 5 is 10 μm;

[0046] The solid electrolyte coating 5 includes the following raw materials, calculated in parts by weight, 1 part of dispersant, 25 parts of solid electrolyte, 3 parts of binder, and 100 parts of solvent.

[0047] The pole piece body includes a positive pole piece 2 and a negative pole piece 3 .

[0048] A method for preparing a pole piece containing a solid electrolyte, comprising the following steps:

[0049] S1: First disperse the dispersant into solvent A to obtain a dispersion solution, then spray the dispersion solution into a container with a solid electrolyte through an atomizing nozzle, and stir for 2 hours at the same time, the stirring speed is 800r / min, and the preparation get dispersion slurry;

[0050] S2: dissolving the binder in solvent B t...

Embodiment 3

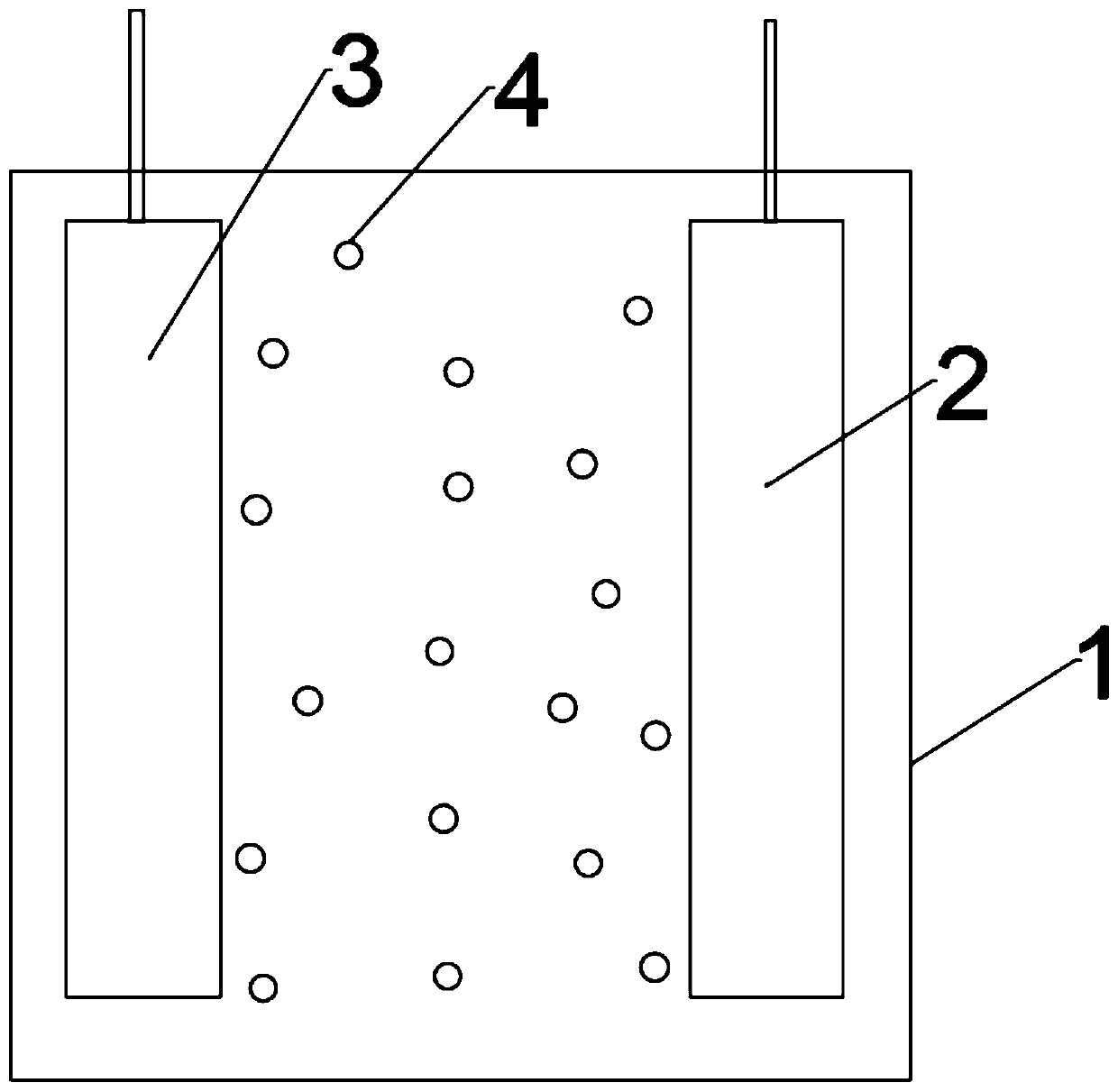

[0063] A pole piece containing a solid electrolyte includes a pole piece body and a solid electrolyte coating 5 coated on both sides of the pole piece body, and the thickness of the solid electrolyte coating 5 is 20 μm;

[0064] The solid electrolyte coating 5 includes the following raw materials, calculated in parts by weight, 2 parts of a dispersant, 40 parts of a solid electrolyte, 5 parts of a binder, and 100 parts of a solvent.

[0065] The pole piece body is a positive pole piece 2 and a negative pole piece 3 .

[0066] A method for preparing a pole piece containing a solid electrolyte, comprising the following steps:

[0067] S1: first disperse the dispersant into solvent A to obtain a dispersion solution, then spray the dispersion solution into a container with a solid electrolyte through an atomizing nozzle, and stir for 3 hours at the same time, with a stirring speed of 800r / min. get dispersion slurry;

[0068] S2: dissolving the binder in solvent B to obtain a bin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com