Plate core of artificial structural plate and manufacturing method thereof

A technology of man-made structure and manufacturing method, which is applied in the direction of manufacturing tools, joining of wooden veneers, chemical instruments and methods, etc., can solve the problems of low production efficiency, low production cost, and single structure, so as to improve production efficiency and save The effect of labor cost and good fastening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

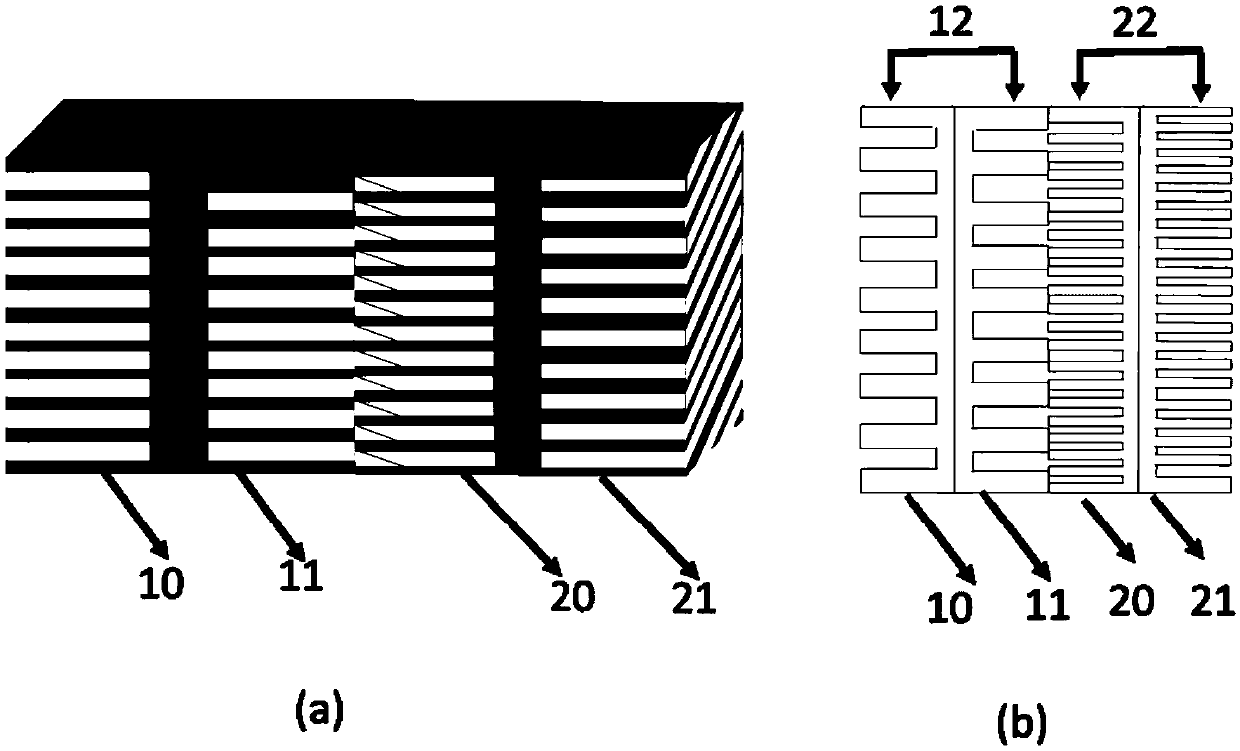

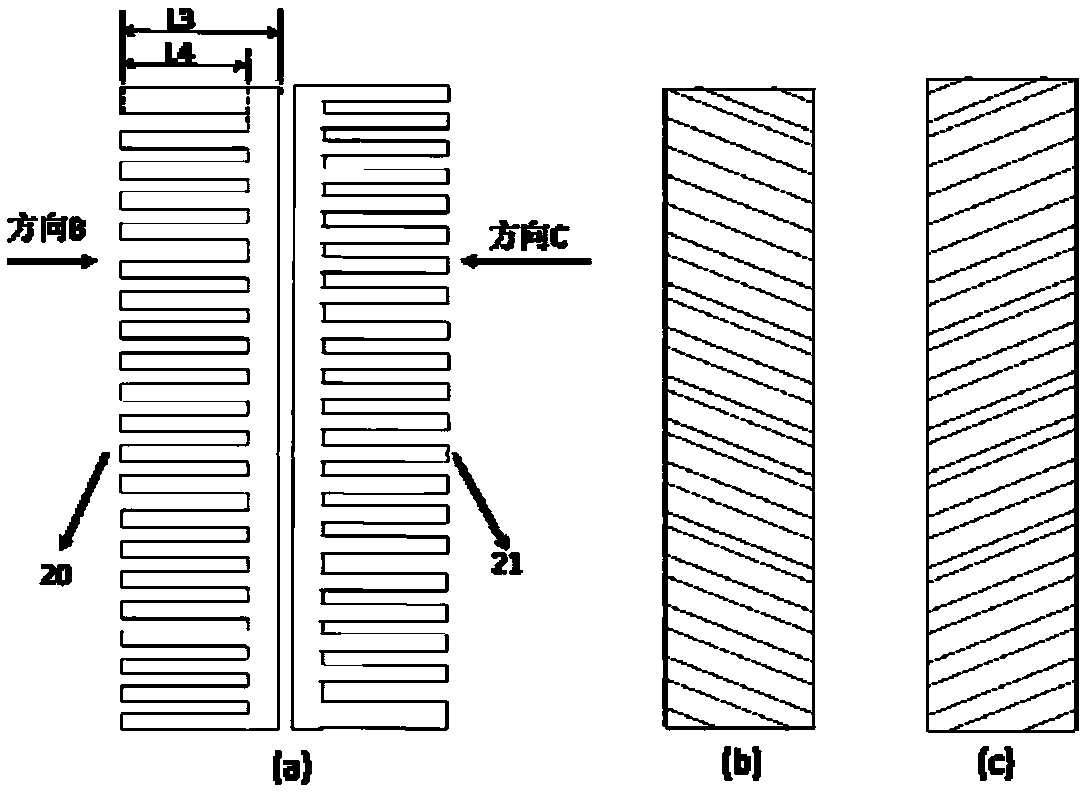

[0076] Specifically, the wood-based panel core provided by the present invention includes multiple groups of core strip units. figure 1 a and figure 1 B is a schematic structural view of the core strip unit of the present invention, which are respectively a three-dimensional structural schematic diagram and a front view of the man-made structure plate core. The core strip unit has a multi-layer structure along the length direction of the plate core, and each group of core strip units includes along the length direction of the plate core. The transverse pressure bearing body (10), the transverse pressure bearing body (11) extending along the length direction of the board core, the cable-stayed structure (20) and (the cable-stayed structure (21) arranged obliquely relative to the transverse pressure bearing body.

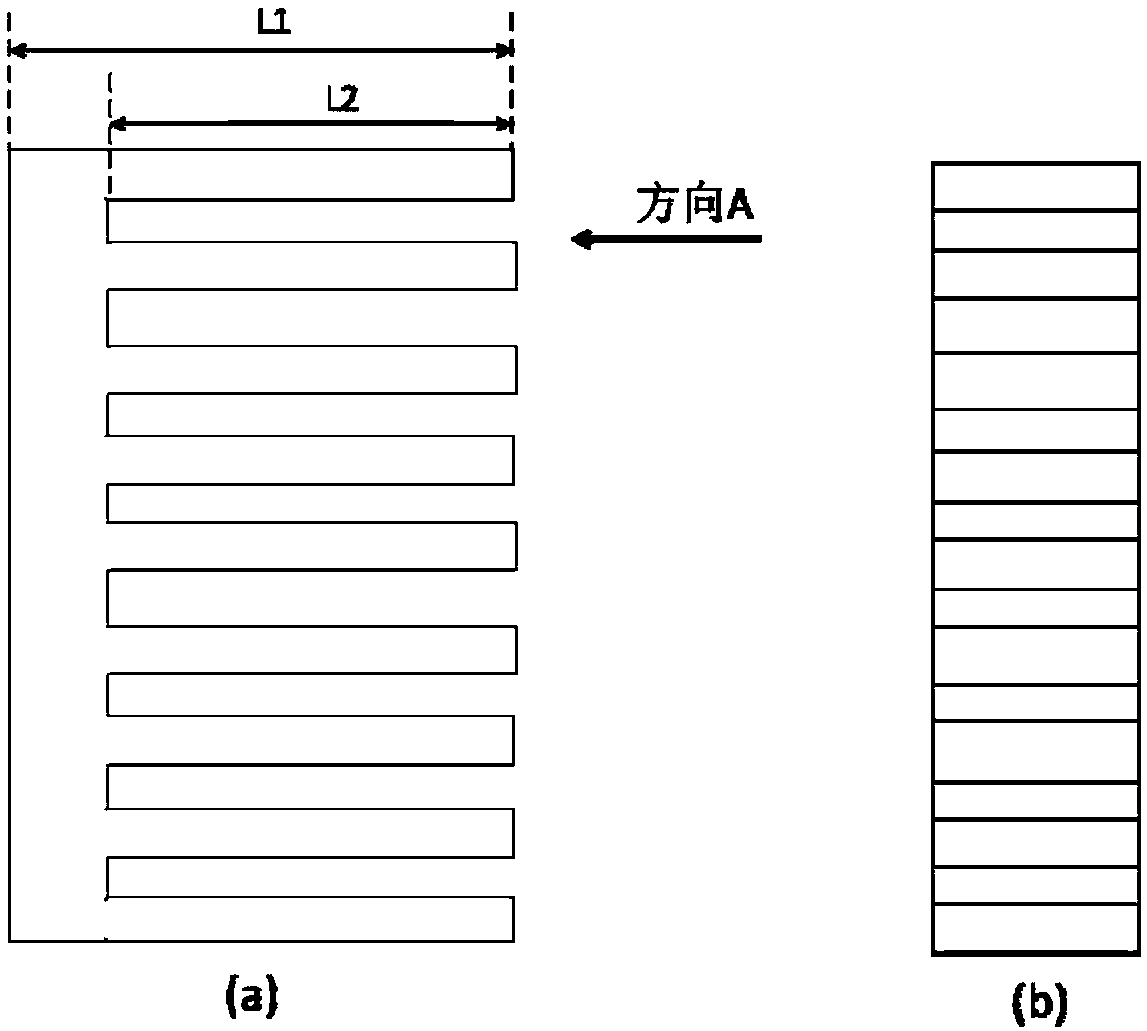

[0077] see figure 2 a is the front view of the lateral pressure-bearing body and figure 2 b is the projected view of the transverse pressure-bearing body along th...

Embodiment 2

[0081] Specifically, the tail end of the lateral pressure bearing body (10) is connected with the tail end of the lateral pressure bearing body (11) to form a double lateral pressure bearing body. The tail end of the pressure bearing body (11) is inserted into the first reinforcing rib, and the first reinforcing rib comprises at least one layer of thin plate. The number of layers and the thickness of the sheets can be increased or decreased as required. For example, it can be one layer of thin plates to N layers of thin plates (N is an integer greater than 1). see Figure 5 a1, Figure 5 a2, Figure 5 b1, Figure 5 b2, Figure 5 c1 and Figure 5 c2. Figure 5 a1 means that the reinforcing rib contained is a layer of thin plate (30), and a layer of thin plate (30) is inserted between the tail end of the transverse pressure bearing body (10) and the tail end of the transverse pressure bearing body (11), wherein the thin plate ( The fiber grain direction of 30) is perpend...

Embodiment 3

[0085] Specifically, a second reinforcing rib is inserted at the joint between the double transverse pressure bearing body and the cable-stayed structure, which serves as the connecting layer between the double transverse pressure bearing body and the cable-stayed structure. The second rib contains at least one layer of thin plate, the specific number of layers and the thickness of the thin plate can be increased or decreased arbitrarily according to the actual situation, see Figure 7 . Figure 7 a1 and Figure 7 a2 is respectively a three-dimensional structural schematic diagram and a front view of the second reinforcing rib containing a thin plate, and the thin plate (40) is superimposed on the head end of the cable-stayed structure (20). Figure 7 a1 and Figure 7 a2 is respectively a three-dimensional structural schematic diagram and a front view of the second reinforcing rib containing a thin plate, and the thin plate (40) is superimposed on the head end of the cable-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com