Resource recovery treatment device for oily sludge

A technology for recycling and recycling, which is used in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. It can solve the problem of high treatment costs, prolonged coking time, and variable three-sludge components. Non-uniformity and other problems, to achieve the effect of reducing processing energy consumption and cost, improving processing capacity and efficiency, and stable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The embodiments in the following description are only examples, and those skilled in the art can think of other obvious modifications. The basic principles of the present invention defined in the following description can be applied to other embodiments, variations, improvements, equivalents and other technical solutions without departing from the spirit and scope of the present invention.

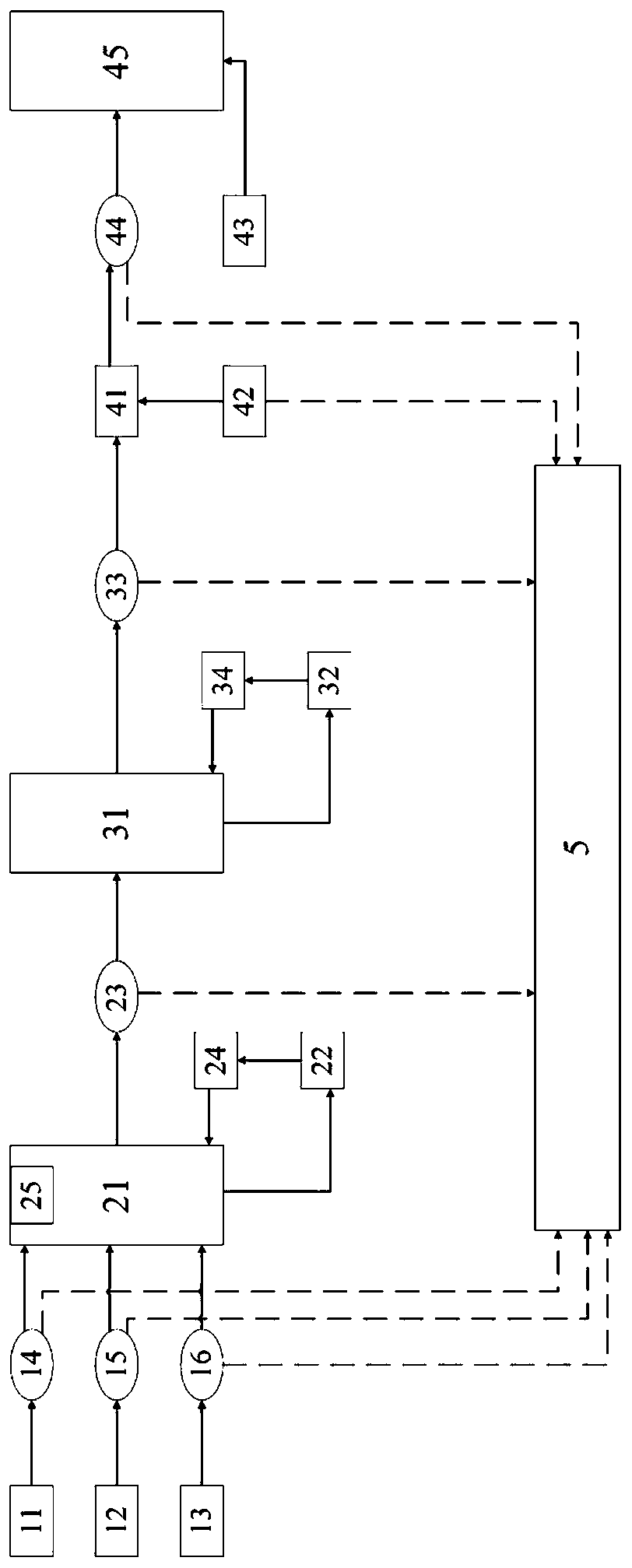

[0027] Refer to attached figure 1 , the present invention provides a recycling treatment device for oily sludge, which is characterized in that it includes a raw material proportioning device 1, a circulation homogenization device 2, a circulation dehydration device 3, a delayed coking device 4 and a PLC control device 5, wherein:

[0028] The raw material proportioning device 1 includes a grease trap bottom mud storage tank 11, a scum storage ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com