Low-temperature continuous heat treatment fixed bed reactor and method

A fixed-bed reactor and reactor technology, applied in the direction of indirect heating dry distillation, special form dry distillation, petroleum industry, etc., can solve the problems of inability to realize continuous feeding and discharging of materials, increase equipment failure rate, reduce processing capacity, etc., and achieve heat utilization High efficiency, low equipment failure rate, and the effect of improving processing capacity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

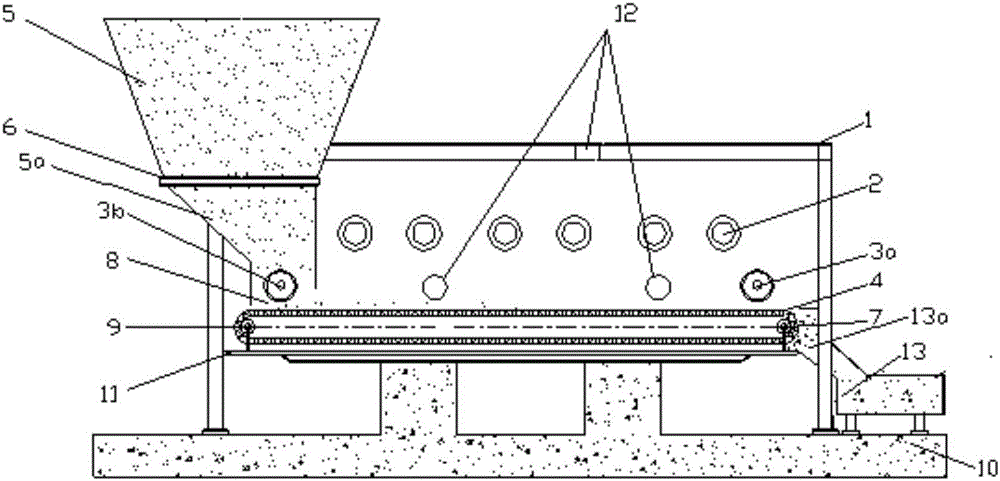

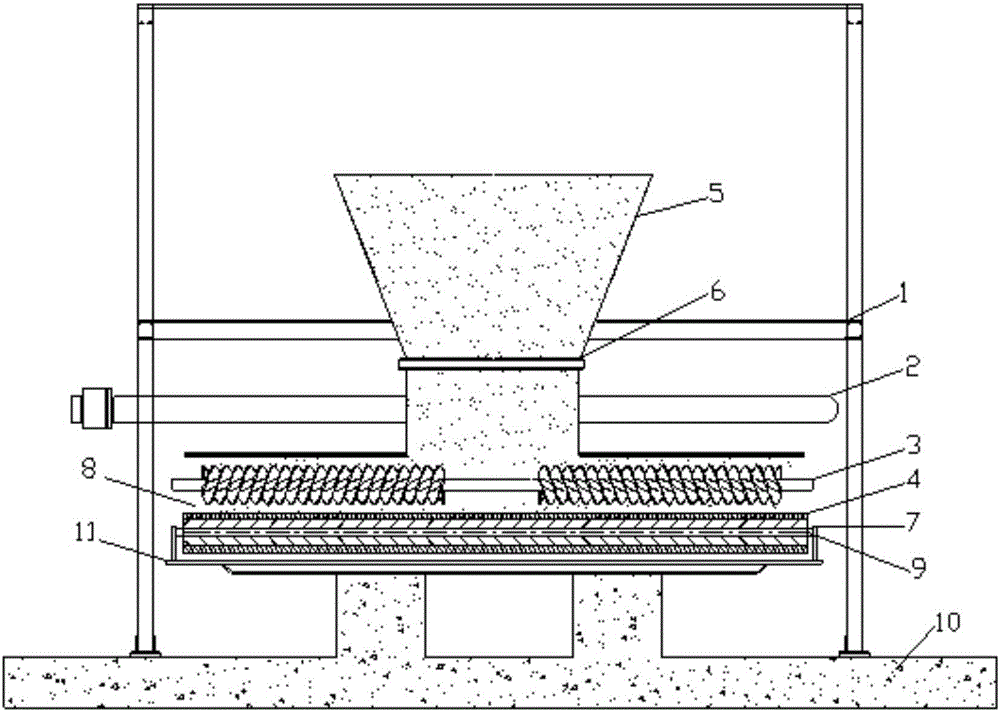

[0111] Coal particles with a particle size of 10 mm to 20 mm provided by PetroChina were used as raw materials (see Table 1 for coal quality analysis data). The material is first stored in the feeding bin 5, the slide valve 6 is opened, and then the material slides down from the feeding chute at the feeding bin 5 into the reaction chamber 8 under the action of gravity.

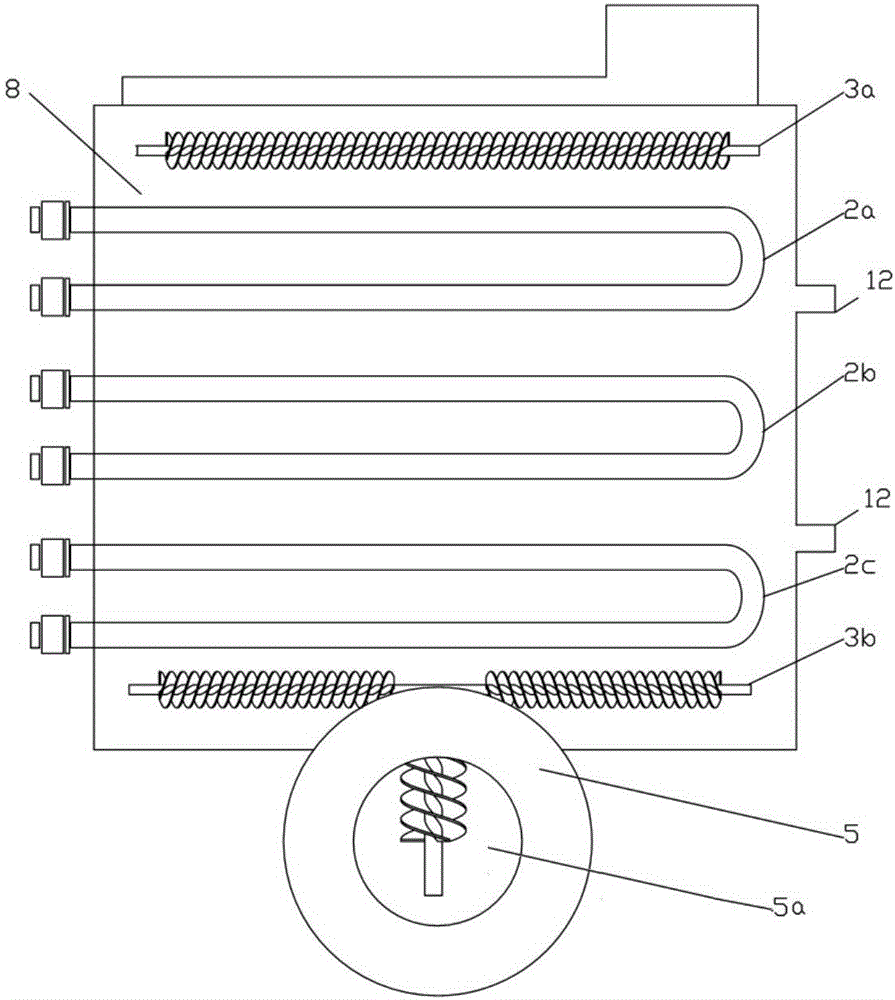

[0112] Under the rotation of the feeding screw 3b and the drive of the transmission bearing 9, the coal particles are evenly distributed on the material plate 4 and move horizontally to the discharge end at the same time. Control the speed of feeding screw 3b and transmission bearing 9, make the material thickness on the whole material plate 4 be 200mm, then close the gate valve 6. Turn on the radiant tube combustion system. When the material temperature is lower than 280°C, control the heating rate of radiant tube 2 to 55°C / min; when the material temperature is higher than 280°C, control the heating rate of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com