A kind of synthetic method of polycarboxylic acid type high slump water reducing agent

A synthesis method and technology of a water reducing agent are applied in the synthesis field of a polycarboxylic acid type high slump-retaining water reducing agent, which can solve the problems of insufficient stability and uniformity of the polymerization reaction, insufficient initiation of the polymerization reaction, and reduced performance of the finished product of the water reducing agent. Improve pore structure and compactness, control slump loss, and improve fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

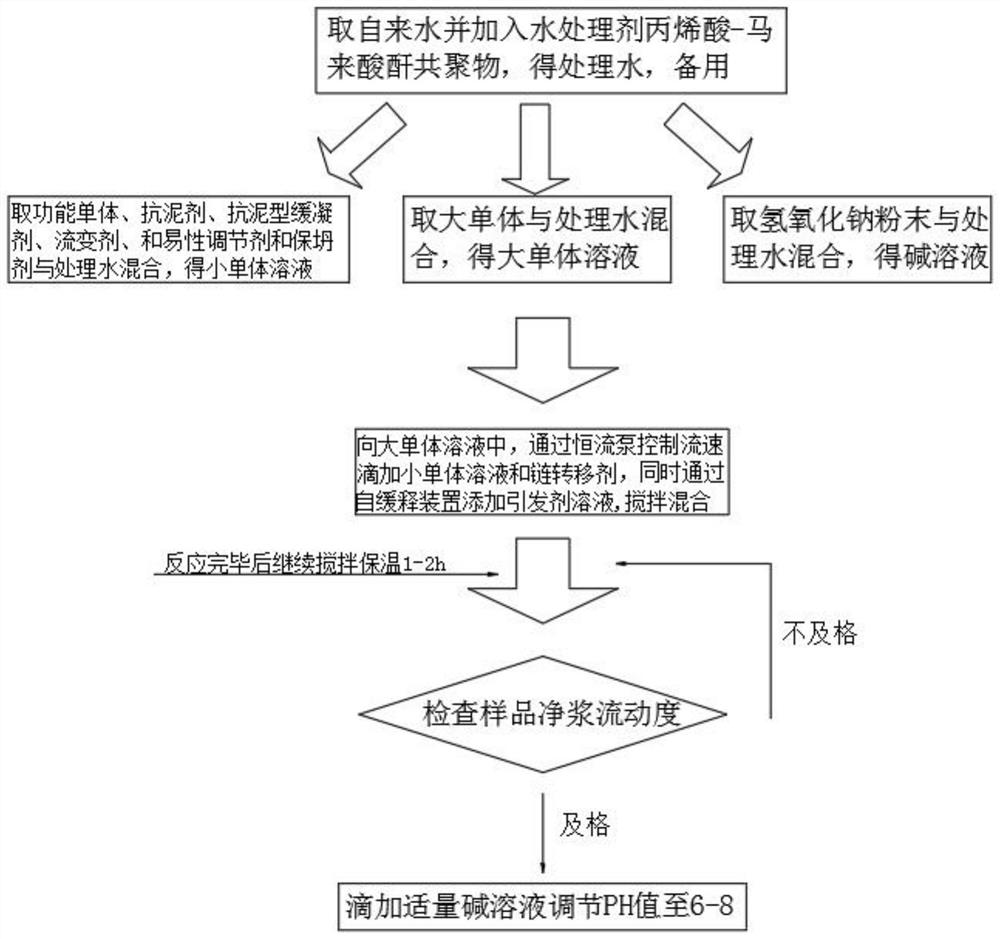

[0049] see figure 1 , a synthetic method of polycarboxylic acid type high slump water reducer, the synthetic method comprises the following steps:

[0050] S1. Prepare treated water: add water treatment agent acrylic acid-maleic anhydride copolymer to tap water until the content of acrylic acid-maleic anhydride copolymer is 3 / L to obtain treated water for later use;

[0051] The molecular weight of the acrylic acid-maleic anhydride copolymer is 2000-5000, and the molar ratio of acrylic acid:maleic anhydride in the acrylic acid-maleic anhydride copolymer is 1.5:1.

[0052] S2. Prepare the macromonomer solution: weigh the macromonomer and the treated water according to the proportion by weight, place them in the reaction kettle to be stirred, dissolve and mix them, stir evenly, and prepare the macromonomer solution, which is set aside;

[0053] The macromonomer is selected from allyl polyoxyethylene ether, methallyl polyoxyethylene ether, butenyl polyoxyethylene ether, methylbu...

Embodiment 2

[0067] see figure 1 , a synthetic method of polycarboxylic acid type high slump water reducer, the preparation method comprises the following steps:

[0068] S1. Preparation of treated water: Add acrylic acid-maleic anhydride copolymer, a water treatment agent, to tap water until the content of acrylic acid-maleic anhydride copolymer is 8 mg / L, to obtain treated water and set aside.

[0069] The molecular weight of the acrylic acid-maleic anhydride copolymer is 2000-5000, and the molar ratio of acrylic acid:maleic anhydride in the acrylic acid-maleic anhydride copolymer is 1.2:1.

[0070] S2. Preparation of a macromonomer solution: weighing the macromonomer and treated water according to the weight ratio, placing them in a reactor to be stirred for dissolving and mixing, and stirring evenly to prepare a macromonomer solution for later use.

[0071] The macromonomer is selected from allyl polyoxyethylene ether, methallyl polyoxyethylene ether, butenyl polyoxyethylene ether, meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com