Core-shell structure sound insulation mortar and preparation method thereof

A core-shell structure and mortar technology, applied in the field of sound insulation materials, can solve the problems of poor sound insulation effect, difficulty in meeting the requirements of building sound insulation performance, poor dissipation of sound wave energy and sound wave ability, etc., to achieve effective absorption and dissipation, excellent sound insulation Effect, high industrial feasibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

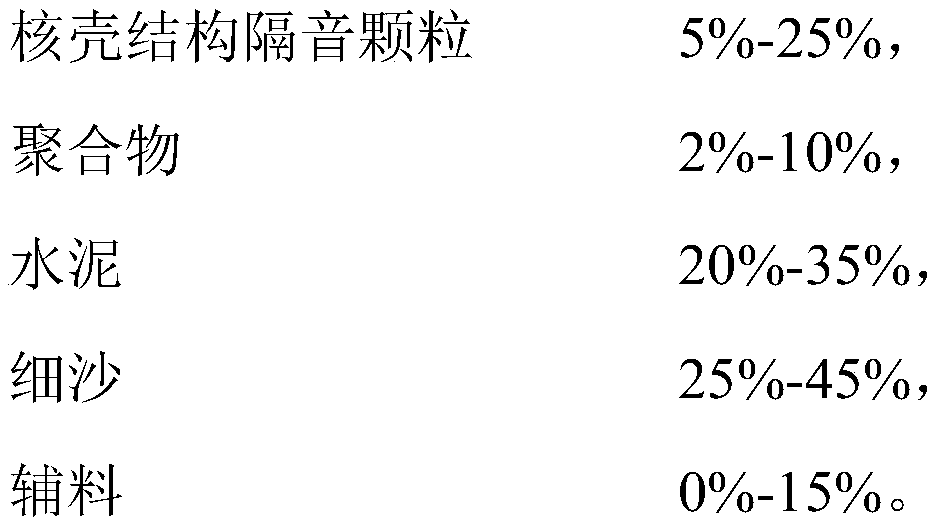

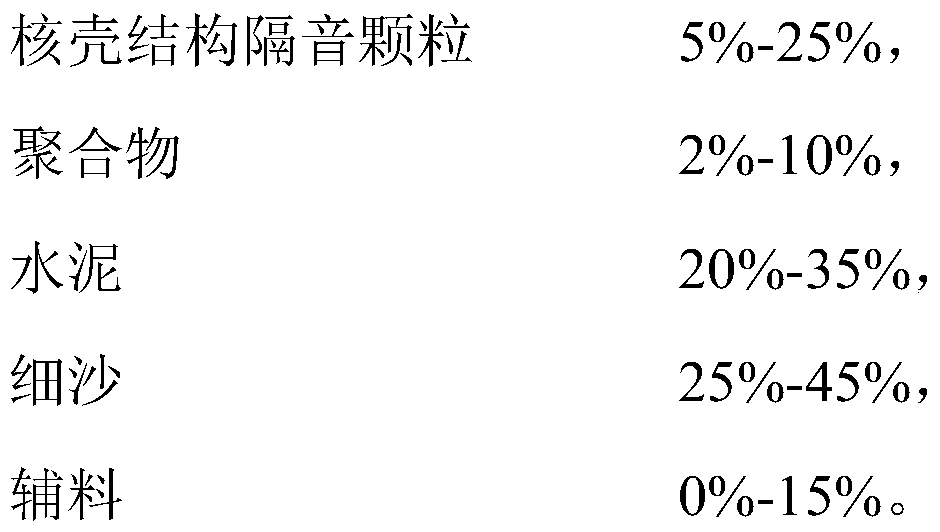

[0046] The embodiment of the present invention also provides a method for preparing a sound-insulating mortar with a core-shell structure, comprising the following steps:

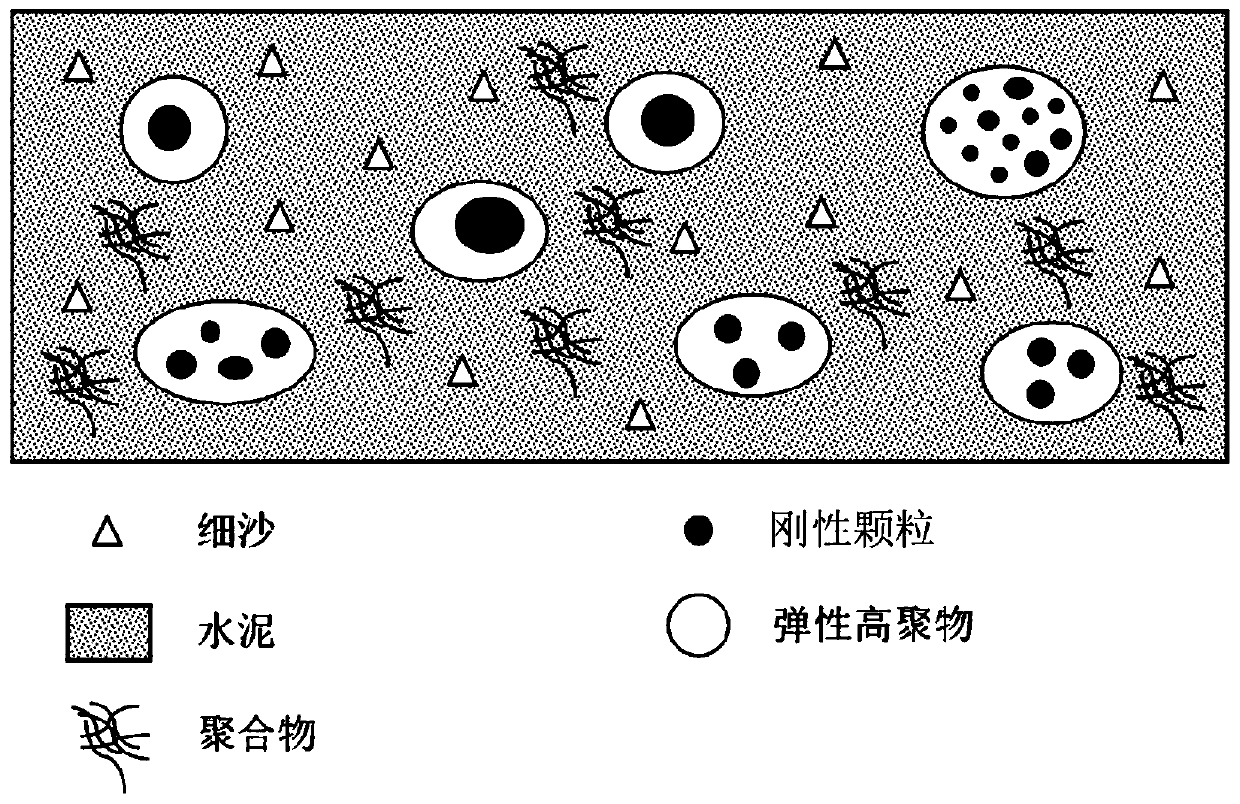

[0047] S10. Obtain rigid particles and elastic high polymers, add the rigid particles to the slurry of the elastic high polymers, mix uniformly, granulate, and screen to obtain sound-insulating particles with a core-shell structure;

[0048] S20. Obtain the formula amount of polymer, cement, fine sand and auxiliary materials, and mix the formula amount of the core-shell sound-insulating particles with the polymer, the cement, the fine sand and the auxiliary materials evenly to obtain the core Acoustic mortar for shell structures.

[0049] The preparation method of the sound-insulating mortar with the core-shell structure provided by the embodiment of the present invention, firstly, add the rigid particles to the slurry of the elastic polymer, mix evenly, granulate and screen to obtain the sound-insulating p...

Embodiment 1

[0054] A sound-insulating mortar with a core-shell structure, prepared by the following method:

[0055] In 1kg of rubber slurry, add 2kg of marble powder with a diameter not greater than 0.2 mm, and mix well. The obtained samples were cut and ground into particles, and screened to obtain sound-insulating particles with a core-shell structure with a particle size of less than 1 mm.

[0056] According to the mass ratio of core-shell structure sound insulation particles, 42.5MPa ordinary Portland cement, fine sand and polyvinyl acetate as 16:33:43:8, the core-shell structure sound insulation particles, 42.5MPa ordinary Portland cement, fine Mix sand and polyvinyl acetate evenly, and prepare a sound-proof mortar with a core-shell structure.

[0057] Put the sound-proof mortar powder into a cone mixer, add an appropriate amount of water, and stir for 15 minutes.

Embodiment 2

[0059] A sound-insulating mortar with a core-shell structure, prepared by the following method:

[0060] Add 2 kg of aluminum chips with a diameter not greater than 0.3 mm to 1 kg of polyurethane in a molten state, and mix well. The obtained samples were cut and ground into particles, and screened to obtain sound-insulating particles with a core-shell structure with a particle size of less than 2 mm.

[0061] According to the mass ratio of core-shell structure sound insulation particles, 42.5MPa ordinary Portland cement, fine sand and polyvinyl acetate as 17:34:42:7, the core-shell structure sound insulation particles, 42.5MPa ordinary Portland cement, fine Sand and polyvinyl acetate are mixed evenly to prepare a sound-insulating mortar with a core-shell structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com