Two-component hybrid matrix system made up of polyurethanes and polymethacrylates for preparation of short fibre reinforced semi-finished products

An acrylate, two-component technology, applied in the field of sheet molding composite materials and molded products, can solve the problems of high melt viscosity, high compression pressure, insufficient quality and mechanical properties of composite materials, etc., and achieve high flexibility The effect of high performance and impact resistance, large degree of freedom, and high mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

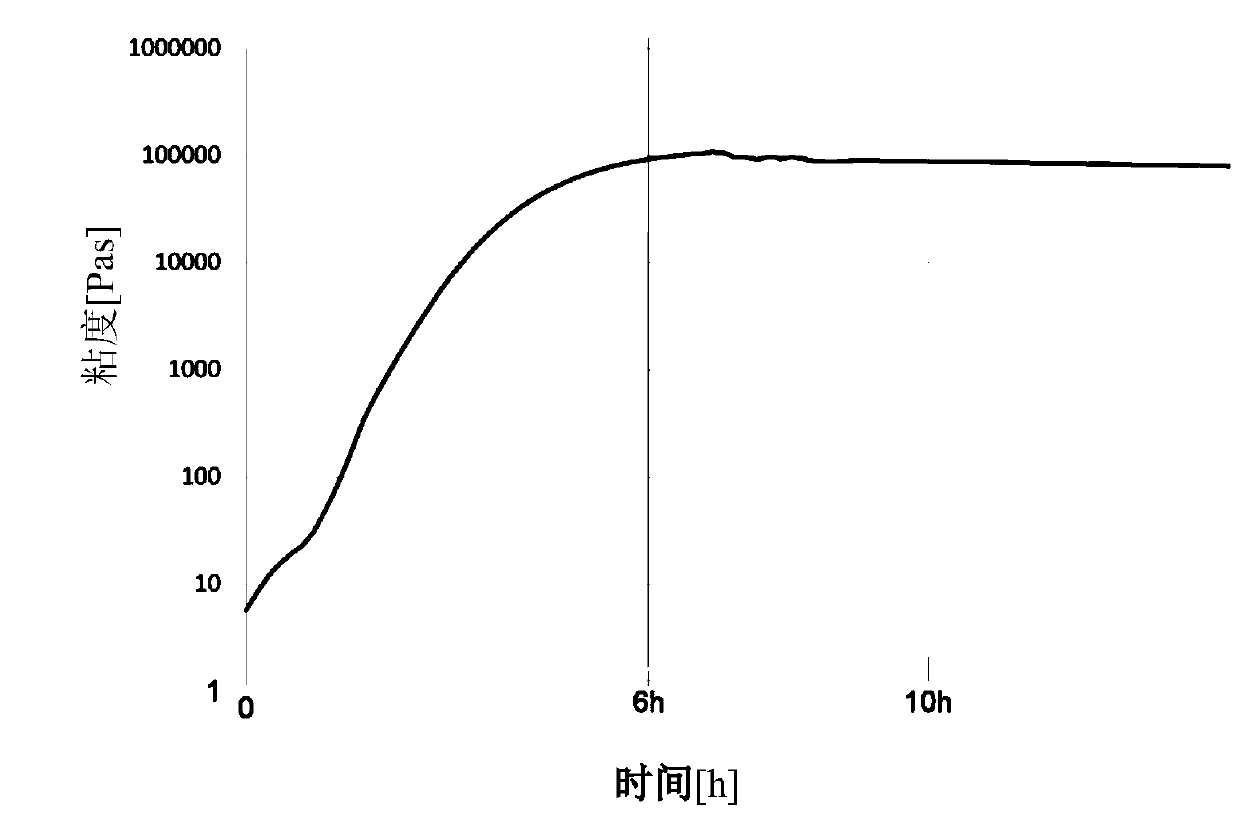

[0116] The procedure begins by providing components A and B. For this, the starting materials are homogenized for 1 hour at room temperature with the aid of a high-speed stirrer. The table below provides some details of the composition of the two components. The viscosity of component A is equal to 2.5 Pas and the viscosity of component B is 1 Pas as measured by the cone and plate method. Table 1 shows the composition of Part A. Table 2 shows the composition of Part B.

[0117] Table 1: Component A

[0118]

[0119] Table 2: Component B

[0120] supplier Feed weight Based on the ratio of component B Ethylene glycol Sigma Aldrich 0.1 mole; 6.2g 28.7% Lupranol 3504 BASF 0.076 mol; 14.9g 68.9% cumene hydroperoxide United Initiators 0.5g 2.31% DBTL Sigma Aldrich 0.027g 0.125% Total 100%

[0121] The resulting low-viscosity component was then applied on a fiber-reinforced Teflon film at a mixing ratio of 2:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com