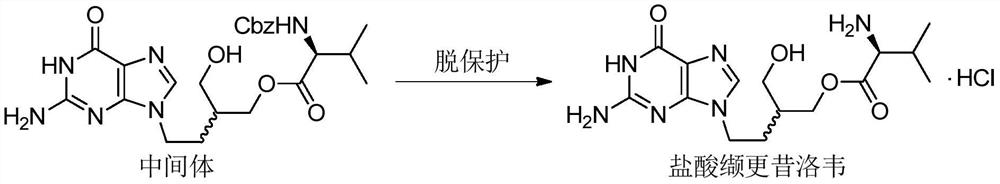

Method for synthesizing valganciclovir hydrochloride by micro-channel reactor

A technology of valganciclovir hydrochloride and microchannel reactor, which is applied in the field of medicine to achieve the effects of suppressing hydrolysis by-products, improving clogging problems and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] S1. Weigh 50kg of the intermediate, add it into 350kg of methanol, add 11kg of hydrochloric acid under stirring, and form material A after fully stirring, and transport material A to module 1 of the microchannel reactor through a plunger pump, and enter the microchannel reactor after preheating and mixing. Reaction module sets of channel reactors;

[0034] S2. Weigh 8.55kg 10% palladium carbon, add in 128kg methanol, fully stir and mix to form material B, transport material B to module 1 of the microchannel reactor through the slurry pump, enter the microchannel reactor after preheating and mixing The reaction module group of;

[0035] S3. The reaction module group that transports hydrogen to the microchannel reactor reacts with the above-mentioned preheated material in the reaction module group, wherein: adjust the flow rate of the plunger pump so that the flow rate of material A is 60.0g / min, adjust the slurry The flow rate of the material pump is such that the flow ...

Embodiment 2

[0045] Embodiment 2 (ethanol)

[0046] S1. Weigh 50kg of the intermediate, add it to 350kg of ethanol, add 11kg of hydrochloric acid under stirring, and form material A after fully stirring, and transport material A to module 1 of the microchannel reactor through a plunger pump, and enter the microchannel reactor after preheating and mixing. Reaction module sets of channel reactors;

[0047] S2. Weigh 8.55kg 10% palladium carbon, add in 128kg ethanol, fully stir and mix to form material B, transport material B to module 1 of the microchannel reactor through the slurry pump, enter the microchannel reactor after preheating and mixing The reaction module group of;

[0048] S3. The reaction module group that transports hydrogen to the microchannel reactor reacts with the above-mentioned preheated material in the reaction module group, wherein: adjust the flow rate of the plunger pump so that the flow rate of material A is 60.0g / min, adjust the slurry The flow rate of the materia...

Embodiment 3

[0051] Embodiment 3 (different reaction temperature)

[0052] S1. Weigh 50kg of the intermediate, add it into 350kg of methanol, add 11kg of hydrochloric acid under stirring, and form material A after fully stirring, and transport material A to module 1 of the microchannel reactor through a plunger pump, and enter the microchannel reactor after preheating and mixing. Reaction module sets of channel reactors;

[0053] S2, take by weighing 8.55kg10% palladium charcoal, add in 128kg methanol, fully stir and mix to form material B, material B is transported in the module one of microchannel reactor through slurry pump, enters the module one of microchannel reactor after preheating and mixing React module group;

[0054] S3. The reaction module group that transports hydrogen to the microchannel reactor reacts with the above-mentioned preheated material in the reaction module group, wherein: adjust the flow rate of the plunger pump so that the flow rate of material A is 60.0g / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com