Detergent production line washing wastewater treatment technology

A wastewater treatment and detergent technology, which is applied in the direction of detergent composition, detergent compounding agent, surface active detergent composition, etc., can solve the problem of no treatment process, etc., and achieve the effect of saving treatment time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

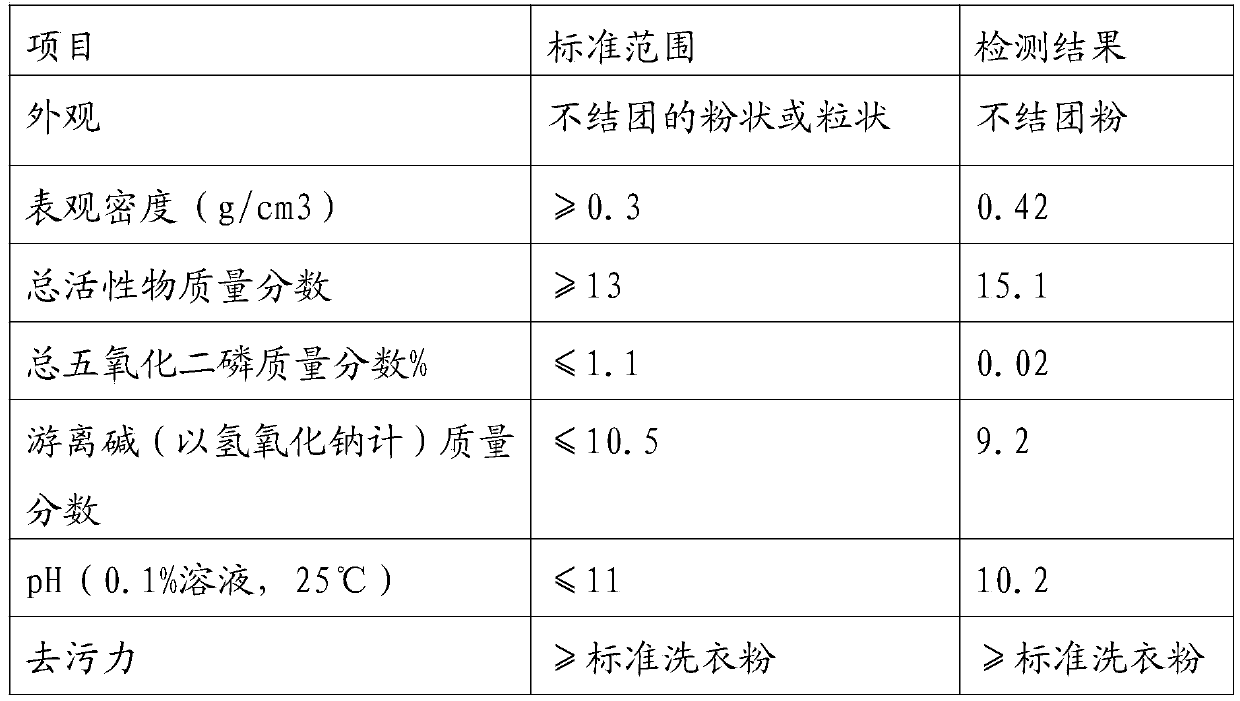

Embodiment 1

[0019] A kind of detergent production line clearing waste water treatment process, comprises the following steps:

[0020] (1) Waste water collection: rinse the equipment used in detergent production with clean water, and collect the waste water after washing from each production equipment;

[0021] (2) Feeding: the waste water collected in step (1), the modulus of which is 3.1 solid sodium silicate and the mass concentration of 35% sodium hydroxide solution are mixed according to the ratio of mass ratio 43:41:16, and are respectively dropped into rotatable horizontal In the type reactor, start the reactor, and the material is stirred and mixed to obtain a reaction solution;

[0022] (3) steaming, pressure control: into the reaction solution of step (2) into the steam of 0.4Mpa, steaming 2h, the pressure in the reactor reaches 0.28Mpa, stop steaming when the initial reaction temperature is 120 ℃, after After 3 hours of reaction, the pressure of the reactor rose to 0.7Mpa, and...

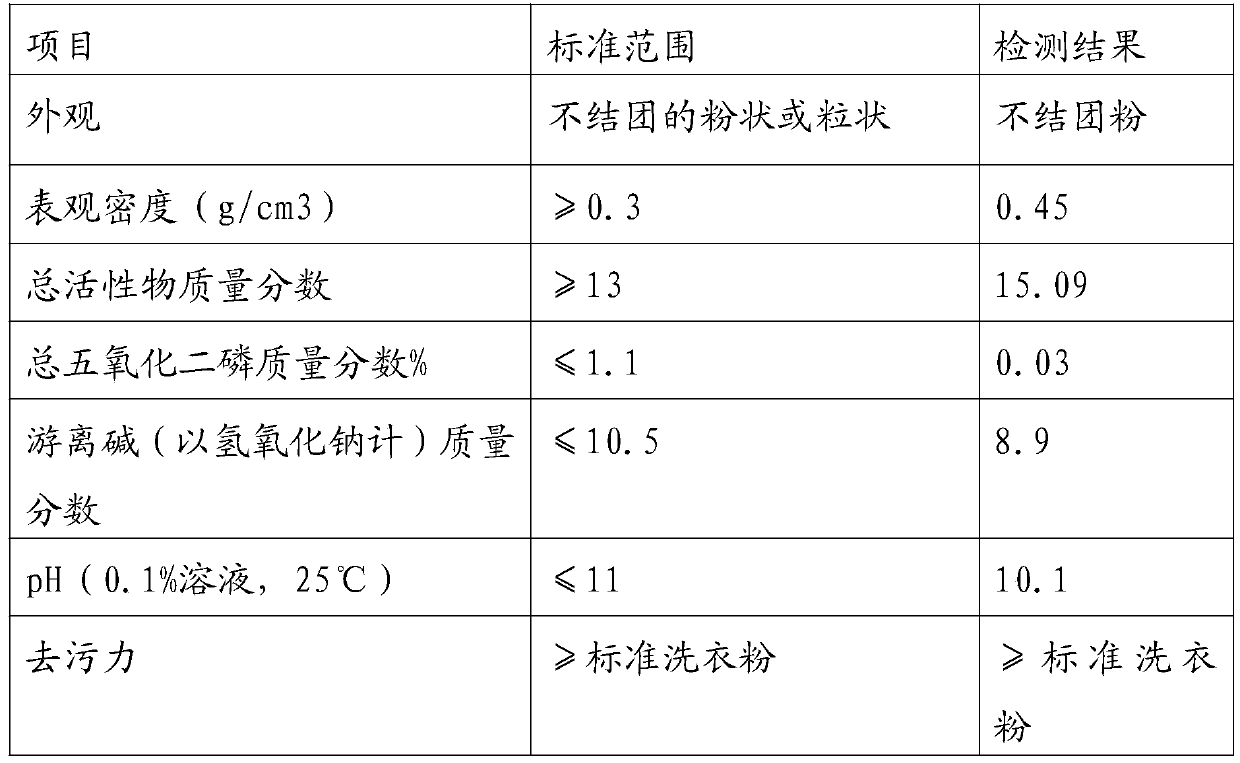

Embodiment 2

[0030] A kind of detergent production line clearing waste water treatment process, comprises the following steps:

[0031] (1) Waste water collection: rinse the equipment used in detergent production with clean water, and collect the waste water after washing from each production equipment;

[0032] (2) Feeding: the wastewater collected in step (1), the modulus of which is 3.4 solid sodium silicate, and the mass concentration of 30% sodium hydroxide solution are mixed according to the ratio of mass ratio 55.4:32.9:11.7, and are respectively dropped into rotatable horizontal In the type reactor, start the reactor, and the material is stirred and mixed to obtain a reaction solution;

[0033] (3) steaming, pressure control: into the reaction solution of step (2) into the steam of 0.6Mpa, steaming 1.2h, the pressure in the reactor reaches 0.35Mpa, stop steaming when the initial reaction temperature is 140 ℃, After 2 hours of reaction, the pressure of the reactor rose to 0.8Mpa, t...

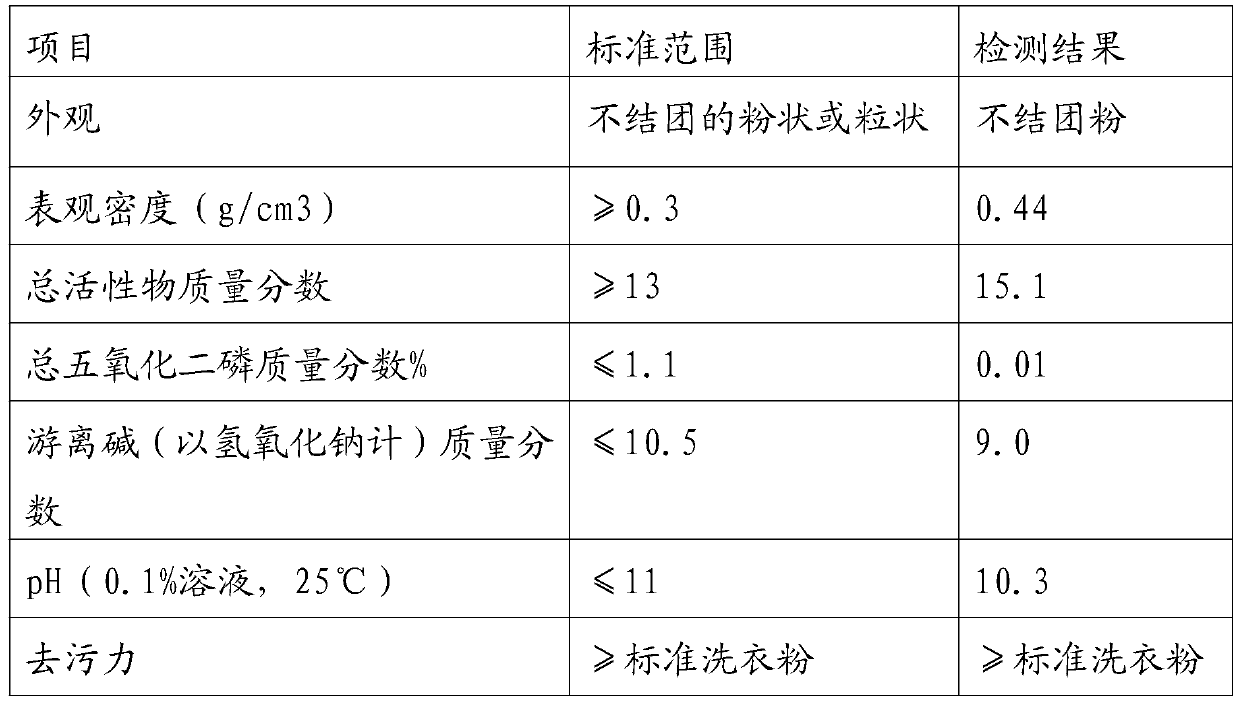

Embodiment 3

[0041] A kind of detergent production line clearing waste water treatment process, comprises the following steps:

[0042] (1) Waste water collection: rinse the equipment used in detergent production with clean water, and collect the waste water after washing from each production equipment;

[0043] (2) Feeding: the waste water collected in step (1), the modulus of which is 3.3 solid sodium silicate and the mass concentration of 32% sodium hydroxide solution are mixed according to the ratio of mass ratio 49.4:37.3:13.3, and are respectively dropped into rotatable horizontal In the type reactor, start the reactor, and the material is stirred and mixed to obtain a reaction solution;

[0044](3) steaming, pressure control: into the reaction solution of step (2) into the steam of 0.5Mpa, steaming 1.5h, the pressure in the reactor reaches 0.35Mpa, stop steaming when the initial reaction temperature is 135°C, After 2 hours of reaction, the pressure of the reactor rose to 0.75Mpa, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com