Composite conductive monofilament and preparation method and application thereof

A composite conductive and monofilament technology, which is applied in the manufacture of conductive/antistatic filaments, rayon, and single-component polyamide rayon. It can solve problems such as rough surface of tow and difficult control of coating thickness. , to achieve the effect of wide application range and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

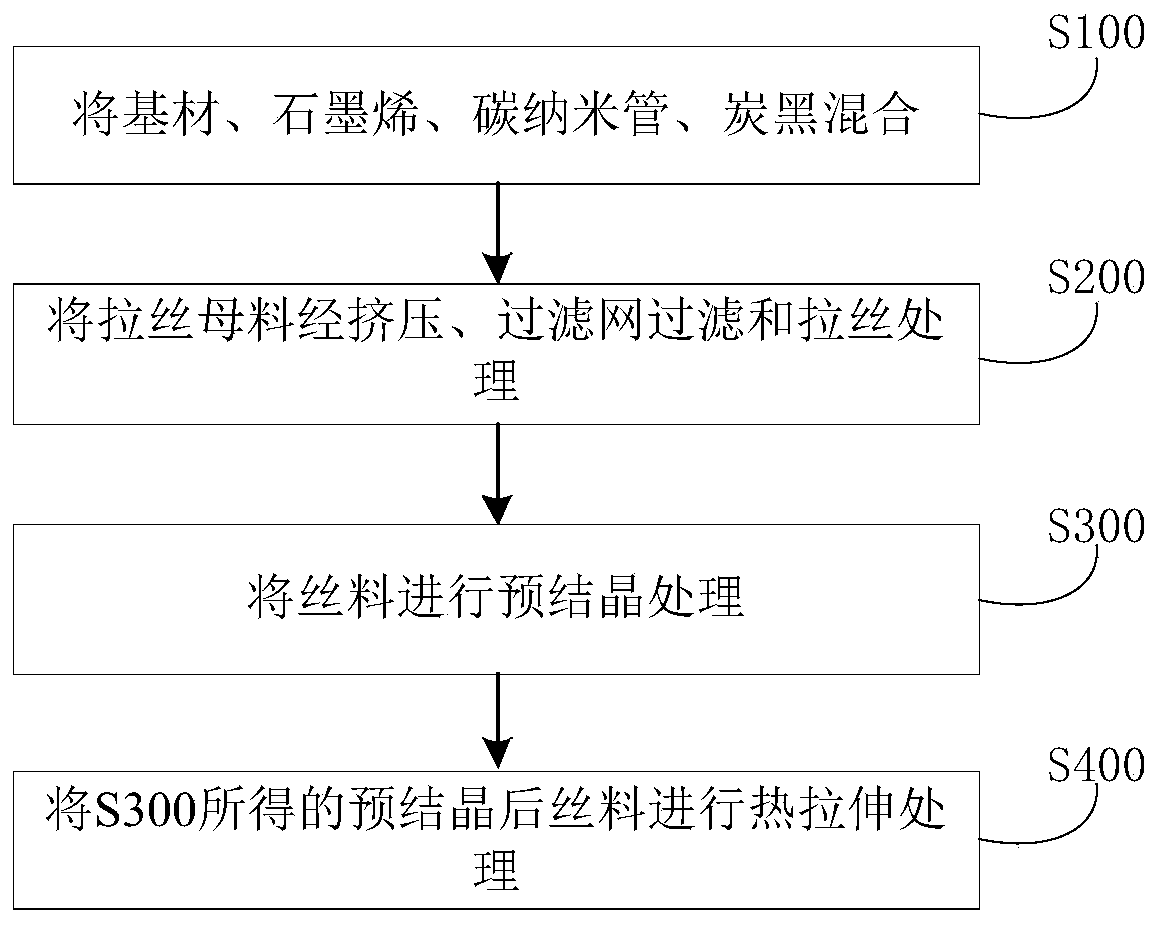

[0048] According to the method for preparing conductive monofilament according to the embodiment of the present invention, the wire drawing masterbatch is prepared by mixing the matrix with graphene, carbon nanotubes, and carbon black, and graphene, carbon nanotubes, and carbon black can be compounded to form three conductive fillers. -Line-surface three-dimensional conductive network, by using the three together with the matrix, the permanent antistatic performance of the composite conductive monofilament can be ensured; The three-dimensional conductive network of the material can be maintained during the subsequent pulling process, avoiding the non-conductive defect of the composite conductive monofilament during the stretching process; by thermally stretching the pre-crystallized silk material, the composite conductive monofilament can be strengthened The strength and make the composite conductive monofilament thinner. The conductivity of the obtained composite conductive m...

Embodiment 1

[0053] The matrix nylon 6 and graphene, carbon nanotubes, carbon black, dispersant EVA-3, antioxidant SKY-1035, and toughening agent SRK-200A are in a mass ratio of 100:3:1:0.5:3:0.2:0.05 Mix to obtain a wire drawing masterbatch with a surface resistance of 25Ω; extrude the wire drawing masterbatch, filter it with a 500-mesh filter and wire drawing treatment to obtain a silk material; pre-crystallize the wire material by heating a metal plate at 230°C ; The pre-crystallized silk material is subjected to thermal stretching treatment at a crimping speed of 200rpm according to a draw ratio of 1.5:1, so as to obtain a composite conductive monofilament with a diameter of 0.105mm.

[0054] The composite conductive monofilament was tested, and its surface resistance was 900Ω, its strength was 57MPa, and its elongation was 120%. After further testing, the ultraviolet protection performance T(UVA) of the composite conductive monofilament AV (%) is 0.2%, T(UVB) AV (%) is 0.5%, the UPF...

Embodiment 2

[0056] The matrix nylon 6 and graphene, carbon nanotubes, carbon black, dispersant EVA-3, antioxidant SKY-1035, and toughening agent SRK-200A are in a mass ratio of 100:4:2:1.5:4:0.5:0.05 Mix to obtain a wire drawing masterbatch with a surface resistance of 77Ω; extrude the wire drawing masterbatch, filter and draw through a filter with a mesh number of 350 meshes, and obtain a silk material; pre-crystallize the wire material by heating a metal plate at 230°C ; The pre-crystallized silk material is subjected to thermal stretching treatment at a crimping speed of 200rpm according to a draw ratio of 1.5:1, so as to obtain a composite conductive monofilament with a diameter of 0.2mm.

[0057]The composite conductive monofilament was tested, and its surface resistance was 280Ω, its strength was 45MPa, and its elongation was 138%. After further testing, the ultraviolet protection performance T(UVA) of the composite conductive monofilament AV (%) is 0.03%, T(UVB) AV (%) is 0.05%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com