Rough surface crack generation method based on digital image technology and test system

A digital image and rough surface technology, applied in the field of test systems for simulating rough surface cracks, can solve the problems of lack of research methods and test methods, inability to perform different tests, and inability to accurately obtain the hydraulic opening of joint surfaces, etc., and achieve wide application Prospect, Ease of Operation, Effect of Convenience Test Method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

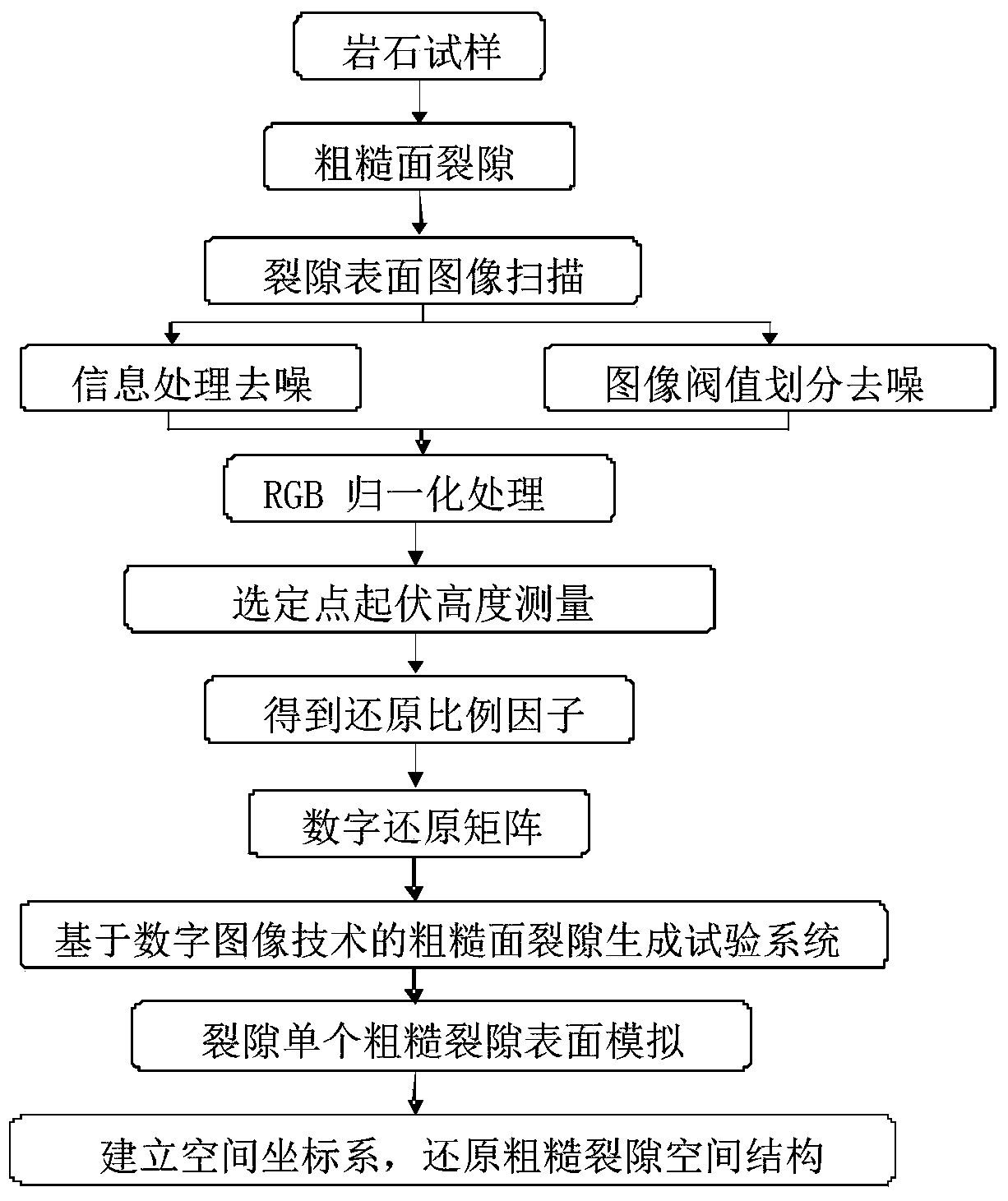

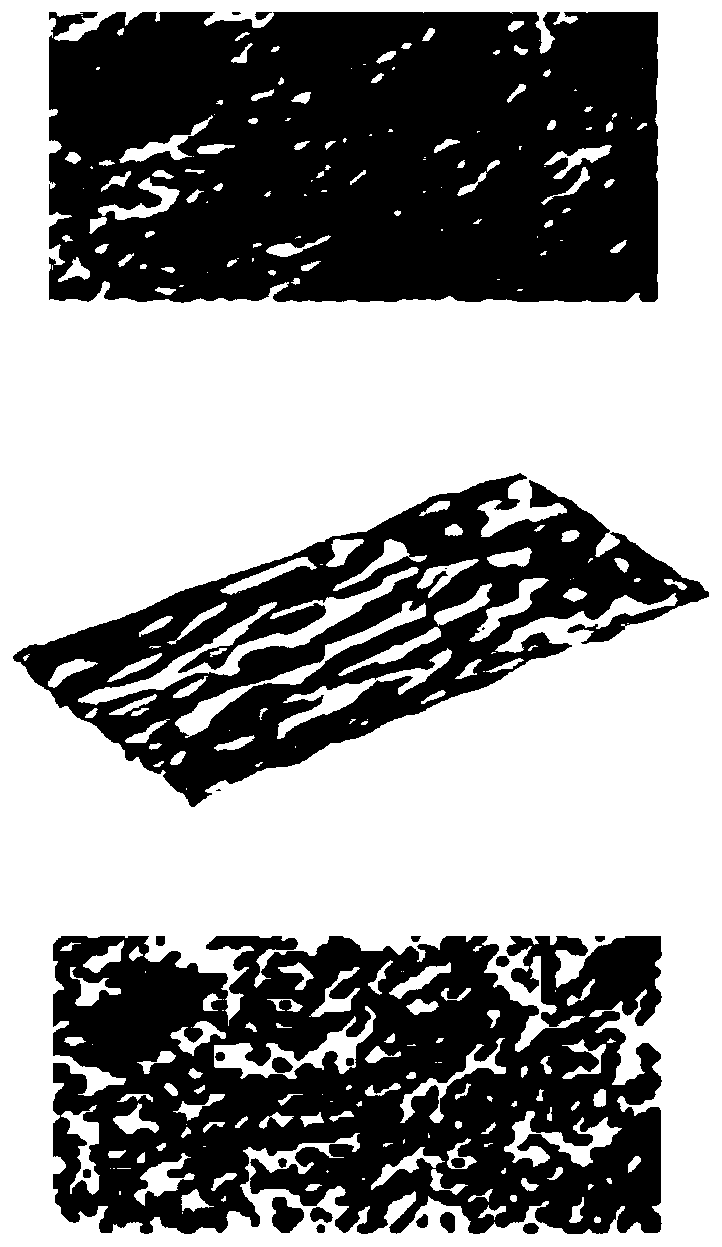

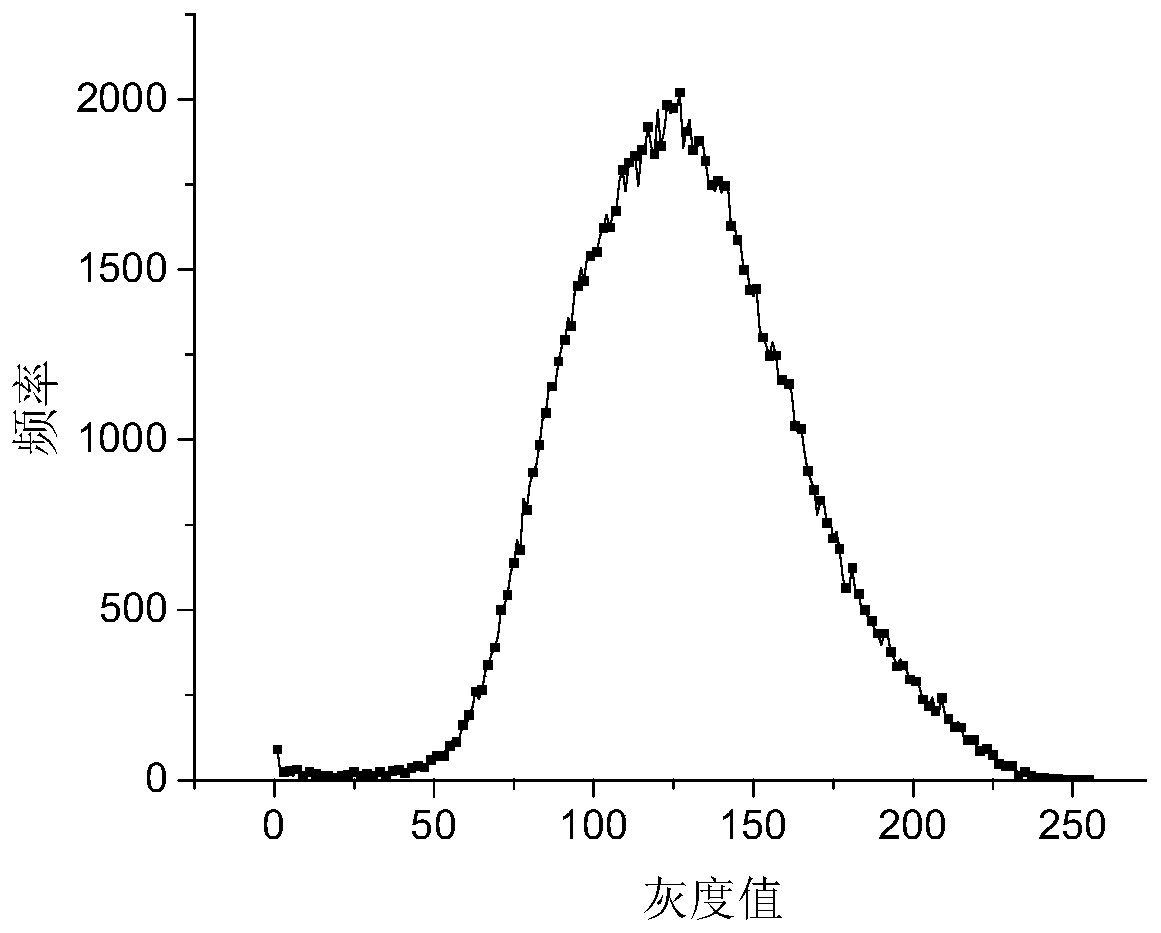

[0047] combine Figure 1 to Figure 12 As shown, a method for generating cracks on a rough surface based on digital image technology and a test system provided by the present invention are specifically implemented as follows.

[0048] The simulation of the rough fracture surface of the rock mass mostly uses resin materials to replicate the rock surface features, and then uses similar materials to reconstruct the fracture surface. In the fluid-solid coupling test, it is impossible to conduct different tests on two specimens with the same fracture condition, and it is difficult to accurately obtain the hydraulic opening of the joint surface. There is a lack of research on the fluid-solid coupling of fractured rock mass from the mesoscopic scale. Necessary research methods and experimental means. The invention obtains the digital image of the fissure surface, establishes a digital model, uses the actual measurement result of a certain point on the rock fissure surface, obtains th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com