A magnetic control reactor core structure and design method

A technology of magnetically controlled reactor and iron core structure, which is applied in the fields of magnetic core manufacturing, transformer/inductor magnetic core, inductor/transformer/magnet manufacturing, etc. Satisfaction and other issues, to achieve the effect of small high-order harmonic content and reduce high-order harmonic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

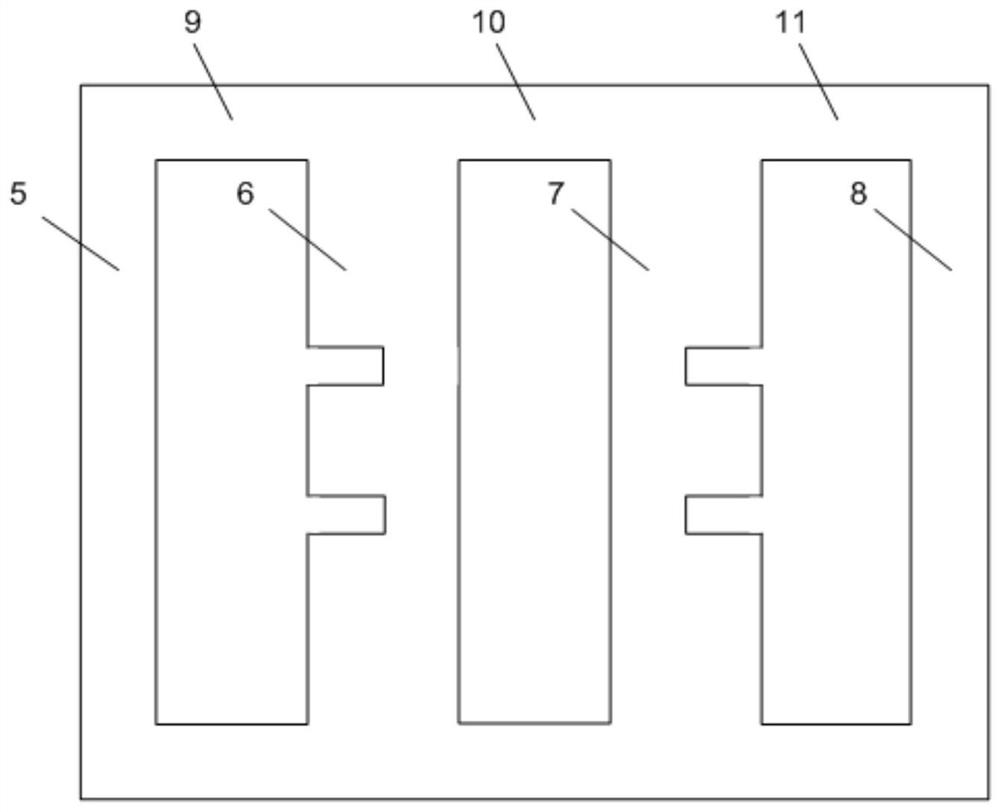

[0034] Such as figure 1 As shown, the magnetically controlled reactor core, the AC magnetic flux generated by the coil on the coil core column I6 circulates in the closed-loop core magnetic circuit formed by the coil core column I6, the AC iron core column I5, and the AC side yoke I9. The AC magnetic flux generated by the coil on the coil core post II7 circulates in the closed-loop core magnetic circuit formed by the coil core post II7, the AC core post II8 and the AC side yoke II11. The DC magnetic flux generated by the coil on the coil core post I6 and the coil core post II7 circulates in the closed-loop core magnetic circuit formed by the coil core post I6, the coil core post II7 and the DC core post 10. Magnetic valves are arranged on the coil iron core post I6 and the coil iron core post II7.

[0035] For the specific reactor coil structure, please refer to CN106026813A. Or select other existing structures, which will not be repeated here.

[0036] The cross-sectional ...

Embodiment 2

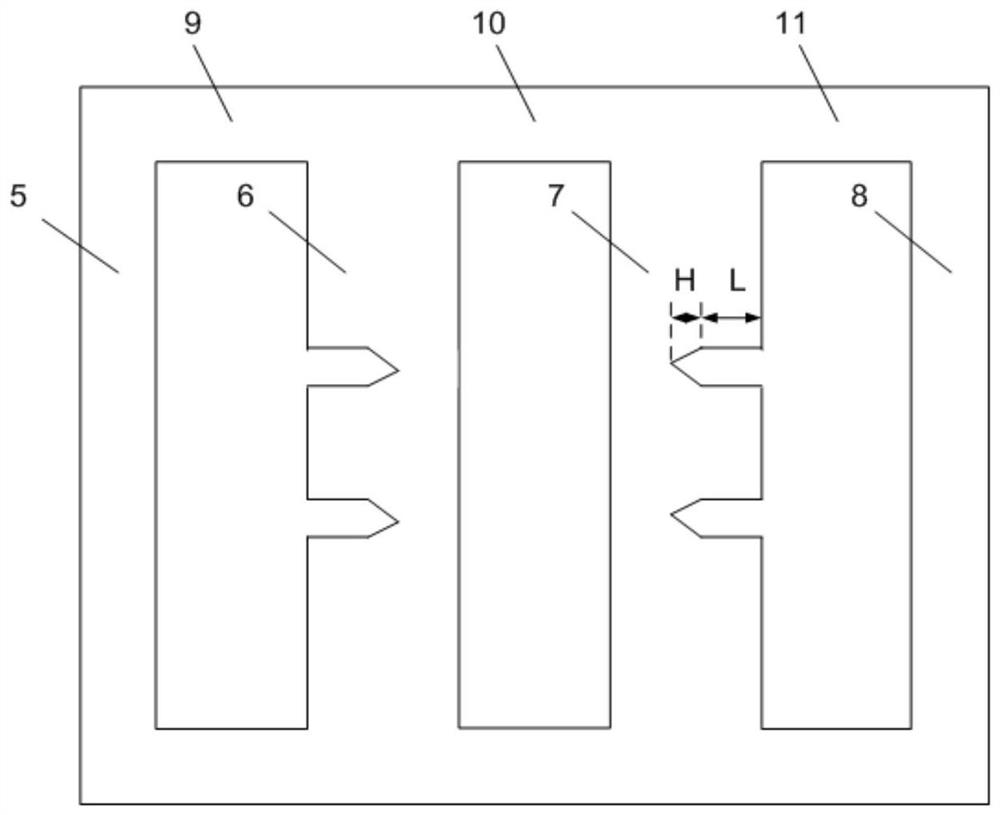

[0047] The magnetic valves on the coil iron core post I and the coil iron core post II are a combination of a rectangle and an isosceles triangle. The rectangular depth of the magnetic valve on the coil core post I and the coil core post II is L, the height of the isosceles triangle is H, and (L / H) is greater than 3 and less than 10. The magnetic valve of this embodiment is a combination of a rectangle and an isosceles triangle. The non-magnetic valve iron core and the magnetic valve transition through an isosceles triangle, which can reduce the ratio of harmonics to fundamental waves in other current states.

[0048] The magnetron reactor of the above embodiment can be designed and manufactured by the existing technology, can be realized completely, and has broad application prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com