A kind of in-situ self-assembled three-dimensional flower-like cobalt disulfide/mxene composite material and its preparation method and application

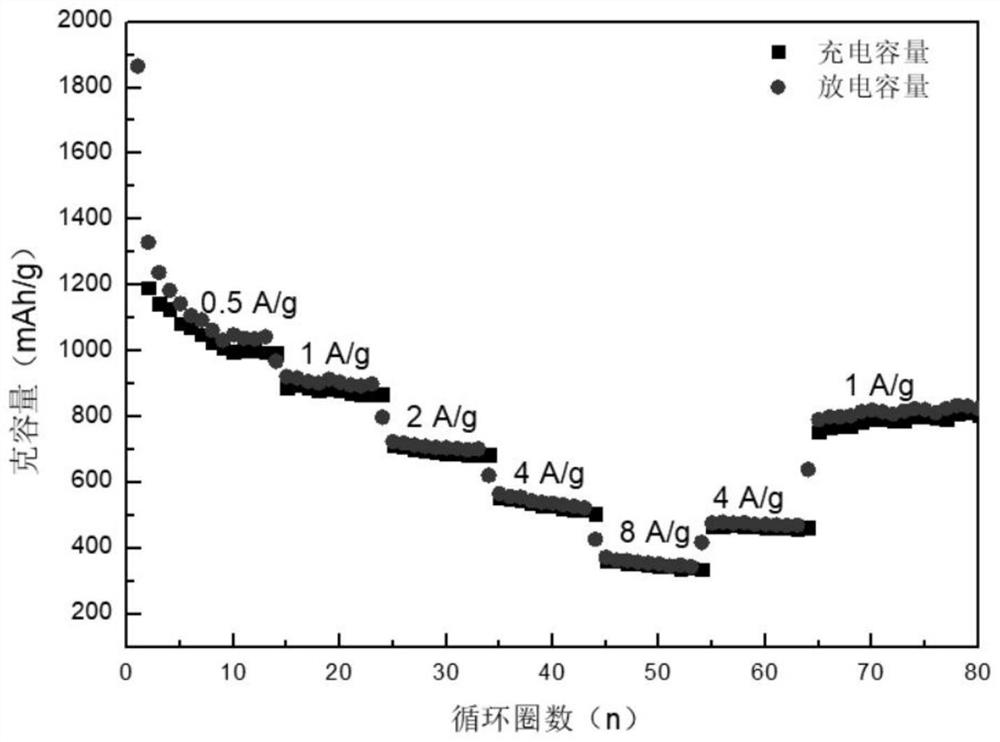

A three-dimensional flower-shaped, composite material technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problem of not fully exerting the reflected value, and achieve excellent charge-discharge cycle performance and rate performance, high first Coulomb efficiency, The effect of high specific capacity electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. 5mmol CoSO 4 ·7H 2 O and 10 mmol Na 2 S were dissolved in 40 mL of deionized water to obtain pink A solution and transparent B solution;

[0032] 2. Slowly add solution A described in step 1 to solution B and mix well, stir well for 30 min to obtain light red solution C;

[0033] 3. Weigh an aqueous solution containing 50 mg of MXene and add it to solution C in step 2, stir for 30 min, and ultrasonically disperse for 10 min to obtain MXene mixed solution D;

[0034] 4. Pour the solution D described in step 3 into a 100 mL stainless steel reaction kettle, then put it into a blast drying oven, keep the temperature at 150 ° C for 36 hours, and then carry out suction filtration after cooling in the furnace to obtain solid D;

[0035] 5. After the solid D described in step 4 is placed in freeze-drying for 24 hours, the in-situ self-assembled nano-flower-like cobalt disulfide / MXene composite material is obtained.

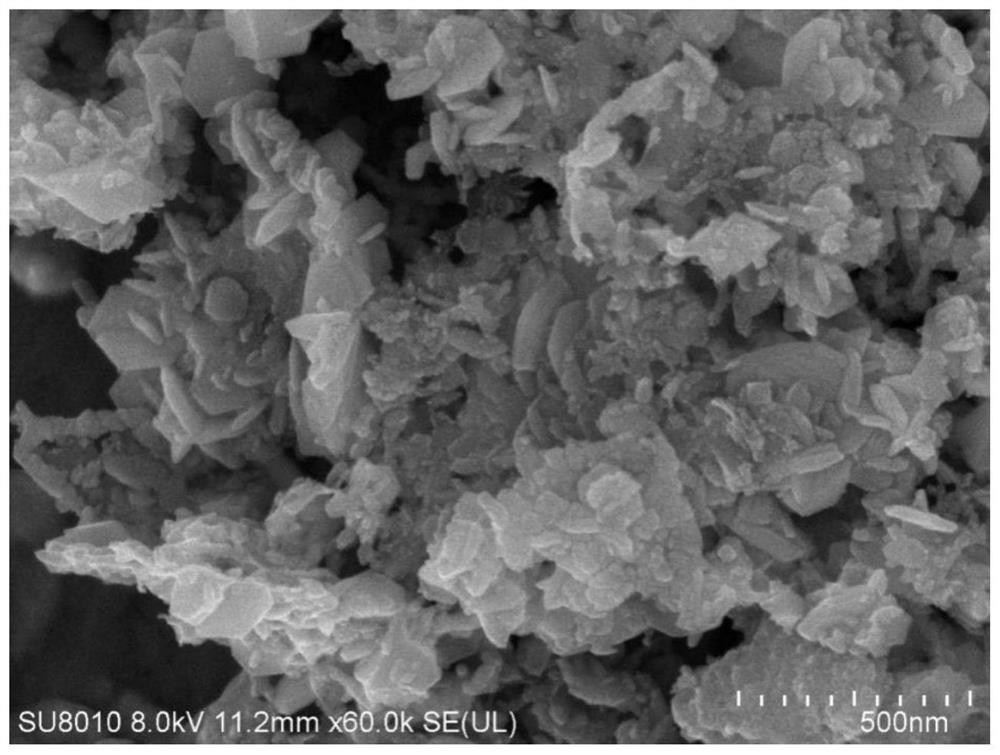

[0036] figure 1 This is the scanning electron microscop...

Embodiment 2

[0038] 1. 3 mmol CoCl 2 ·6H 2 O and 3mmol TAA (thioacetamide) were dissolved in 40mL deionized water respectively to obtain pink A solution and transparent B solution;

[0039] 2. Slowly add solution A in step 1 to solution B and mix well, stir well for 30 min to obtain light red solution C;

[0040] 3. Weigh the aqueous solution containing 30 mg of MXene and add it to solution C in step 2, stir for 30 min, and ultrasonically disperse for 10 min to obtain MXene mixed solution D;

[0041] 4. Pour the solution D in step 3 into a 100mL stainless steel reaction kettle, then put it into a blast drying oven, keep it at 150 ° C for 36 hours, and then carry out suction filtration after cooling in the furnace to obtain solid D;

[0042] 5. After the solid D in step 4 is placed in a freezer for 24 hours for drying, the in-situ self-assembled nano-flower-like cobalt disulfide / MXene composite material is obtained.

Embodiment 3

[0044] 1. Put 3mmolC 4 H 6 CoO 4 and 3mmol L-cysteine were respectively dissolved in 40mL deionized water to obtain A solution and B solution;

[0045] 2. Slowly add solution A in step 1 to solution B and mix well, stir well for 30 min to obtain light red solution C;

[0046] 3. Weigh the aqueous solution containing 30 mg of MXene and add it to solution C in step 2, stir for 30 min, and ultrasonically disperse for 10 min to obtain MXene mixed solution D;

[0047] 4. Pour the solution D in step 3 into a 100 mL stainless steel reaction kettle, and then put it into a blast drying oven, keep it at 280 ° C for 12 hours, and then perform suction filtration after cooling in the furnace to obtain solid D;

[0048] 5. After the solid D in step 4 is placed in a freezer for 24 hours for drying, the in-situ self-assembled nano-flower-like cobalt disulfide / MXene composite material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com