Porphyrin/aluminum oxide nano-channel membrane and application thereof in energy conversion device

A kind of aluminum oxide nanometer and nanochannel technology, which is applied in the direction of generators, electrical components, generators/motors, etc. that convert kinetic energy into electrical energy, and can solve problems such as limiting transmembrane current flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

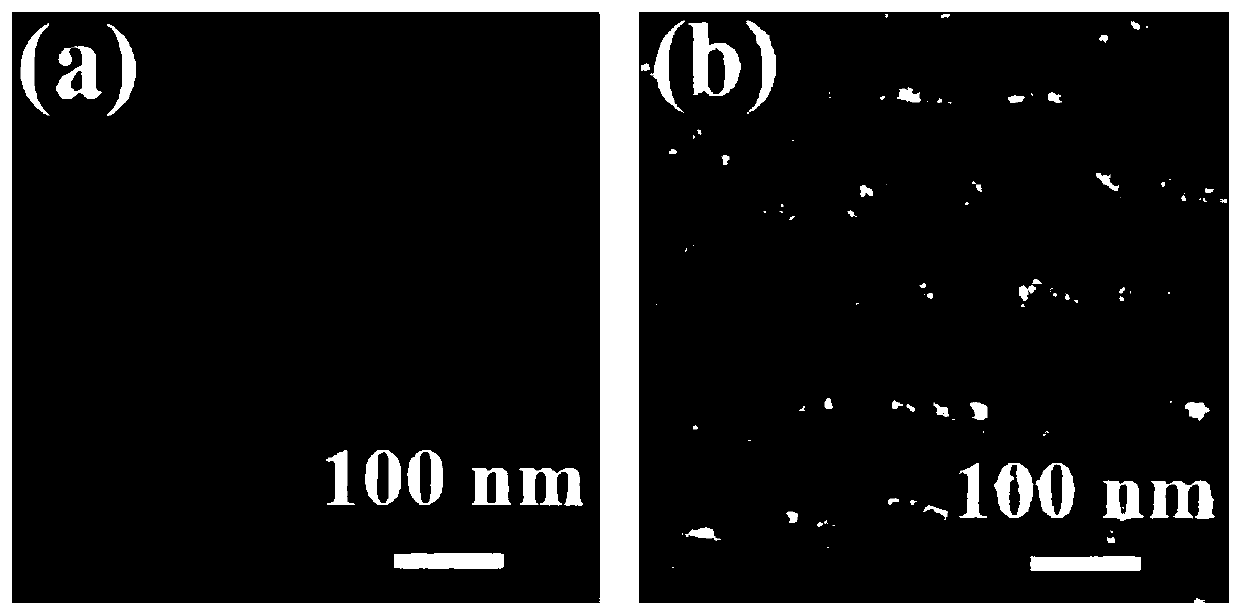

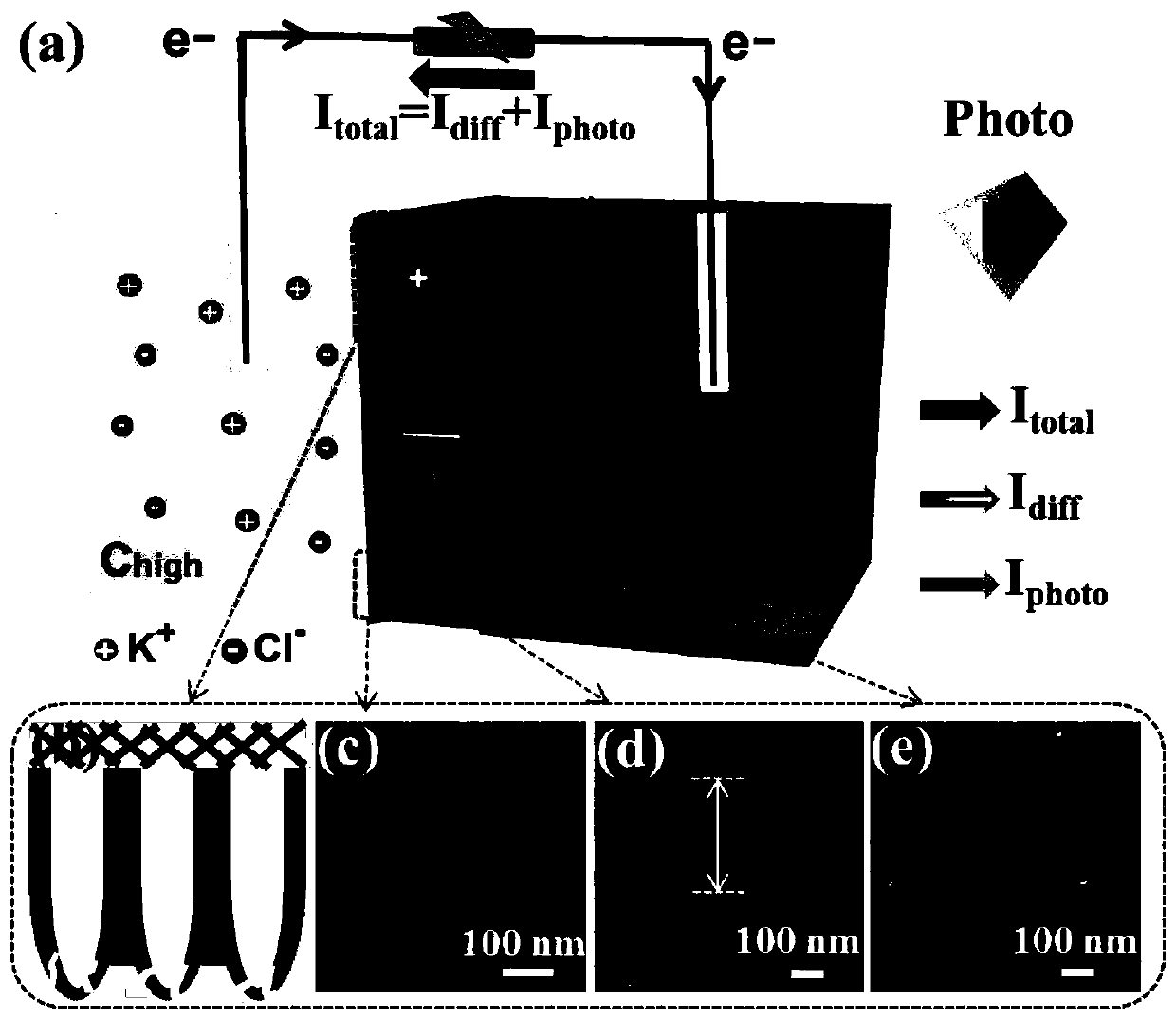

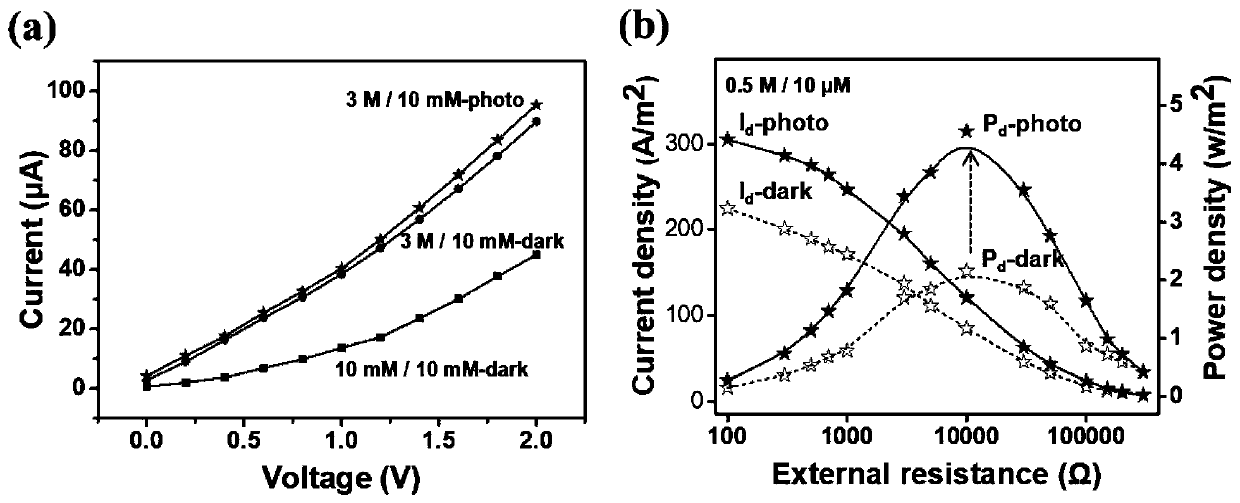

[0064] A specific preparation process of a porphyrin / alumina nanochannel membrane is as follows:

[0065] (1) A two-step anodic oxidation method is used to prepare an aluminum oxide film with one end sealed and a thickness of 50 μm and a surface pore diameter of 50 nm, washed, and naturally air-dried for use;

[0066] (2) preparation concentration is that the TPPS aqueous solution of 5mmol / L and concentration are 0.5mol / L sodium chloride aqueous solution, and the aluminum oxide film that step (1) makes is placed in the two chambers that fill TPPS aqueous solution and sodium chloride aqueous solution respectively The connection between the two tanks is used to isolate the electrolyte contained in the above two tanks;

[0067] (3) The deposition of 120min occurs simultaneously in the tanks on both sides of the aluminum oxide film arranged in step (2), and TPPS is deposited at the opening of the aluminum oxide film to self-assemble to form a TPPS nanofiber film with a thickness o...

Embodiment 2

[0070] A specific preparation process of a porphyrin / alumina nanochannel membrane is as follows:

[0071] (1) A two-step anodic oxidation method is used to prepare an aluminum oxide film with one end sealed and a thickness of 40 μm and a surface pore diameter of 60 nm, washed, and naturally air-dried for use;

[0072] (2) preparation concentration is that the TPPS aqueous solution of 6mmol / L and concentration are 0.6mol / L sodium chloride aqueous solution, and the aluminum oxide thin film that step (1) makes is placed in the two chambers that fill TPPS aqueous solution and sodium chloride aqueous solution respectively The connection between the two tanks is used to isolate the electrolyte contained in the above two tanks;

[0073] (3) Deposition of 200 min occurs simultaneously in the tanks on both sides of the aluminum oxide film arranged in step (2), and TPPS is deposited at the opening of the aluminum oxide film to self-assemble to form a TPPS nanofiber film with a thickness...

Embodiment 3

[0076] A specific preparation process of a porphyrin / alumina nanochannel membrane is as follows:

[0077] (1) A two-step anodic oxidation method is used to prepare an aluminum oxide film with one end sealed and a thickness of 70 μm and a surface pore diameter of 60 nm, washed, and naturally air-dried for use;

[0078] (2) preparation concentration is that the TPPS aqueous solution of 2mmol / L and concentration are 0.3mol / L sodium chloride aqueous solution, and the aluminum oxide thin film that step (1) makes is placed in the two chambers that fill TPPS aqueous solution and sodium chloride aqueous solution respectively The connection between the two tanks is used to isolate the electrolyte contained in the above two tanks;

[0079] (3) The deposition of 300min occurs simultaneously in the tanks on both sides of the aluminum oxide film arranged in step (2), and TPPS is deposited at the opening of the aluminum oxide film to self-assemble to form a TPPS nanofiber film with a thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com