Modification process of lithium ion battery cathode material

A lithium-ion battery, cathode material technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of long time consumption, easy breakage, particle breakage, etc., to improve production safety, stable electrochemical performance, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

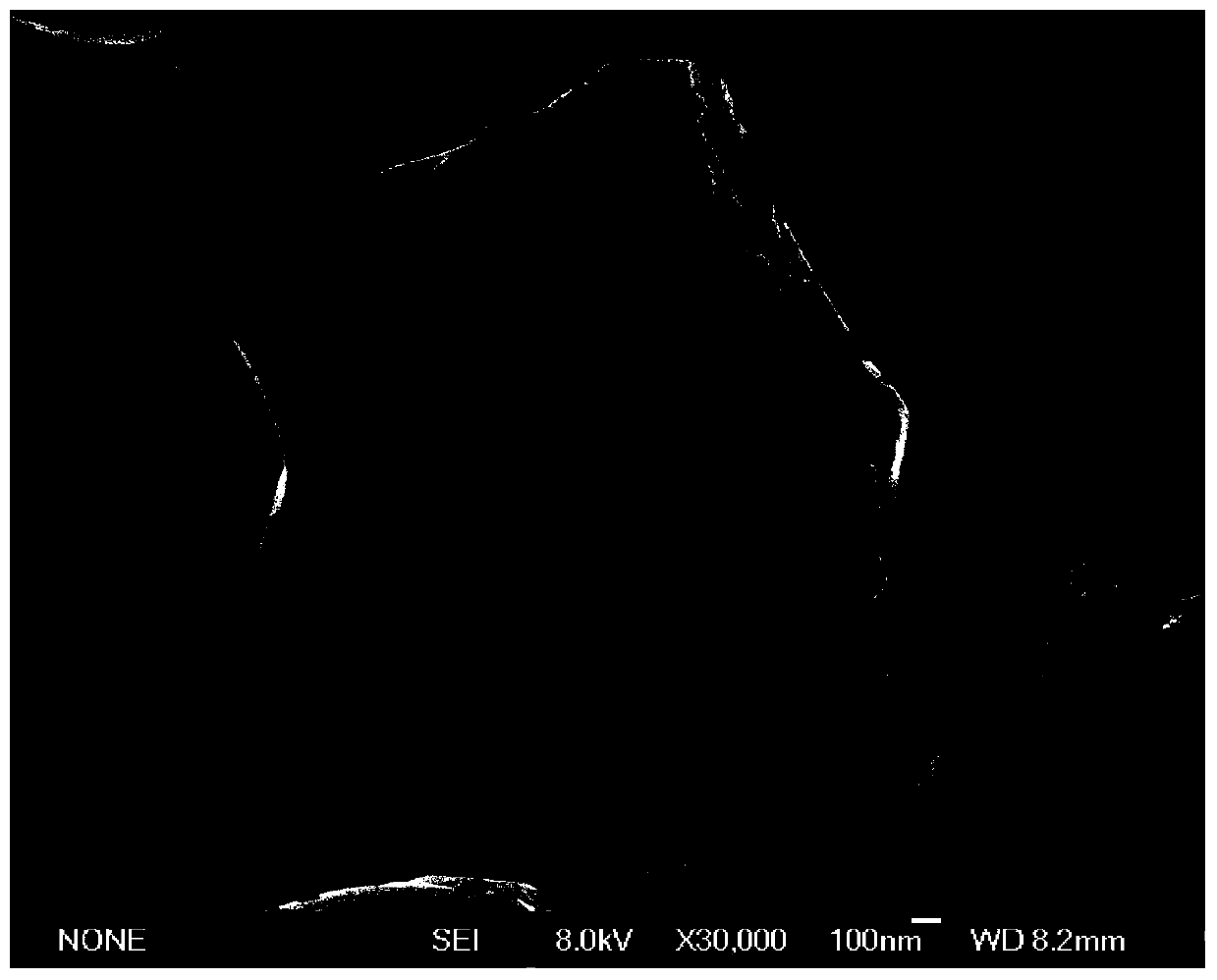

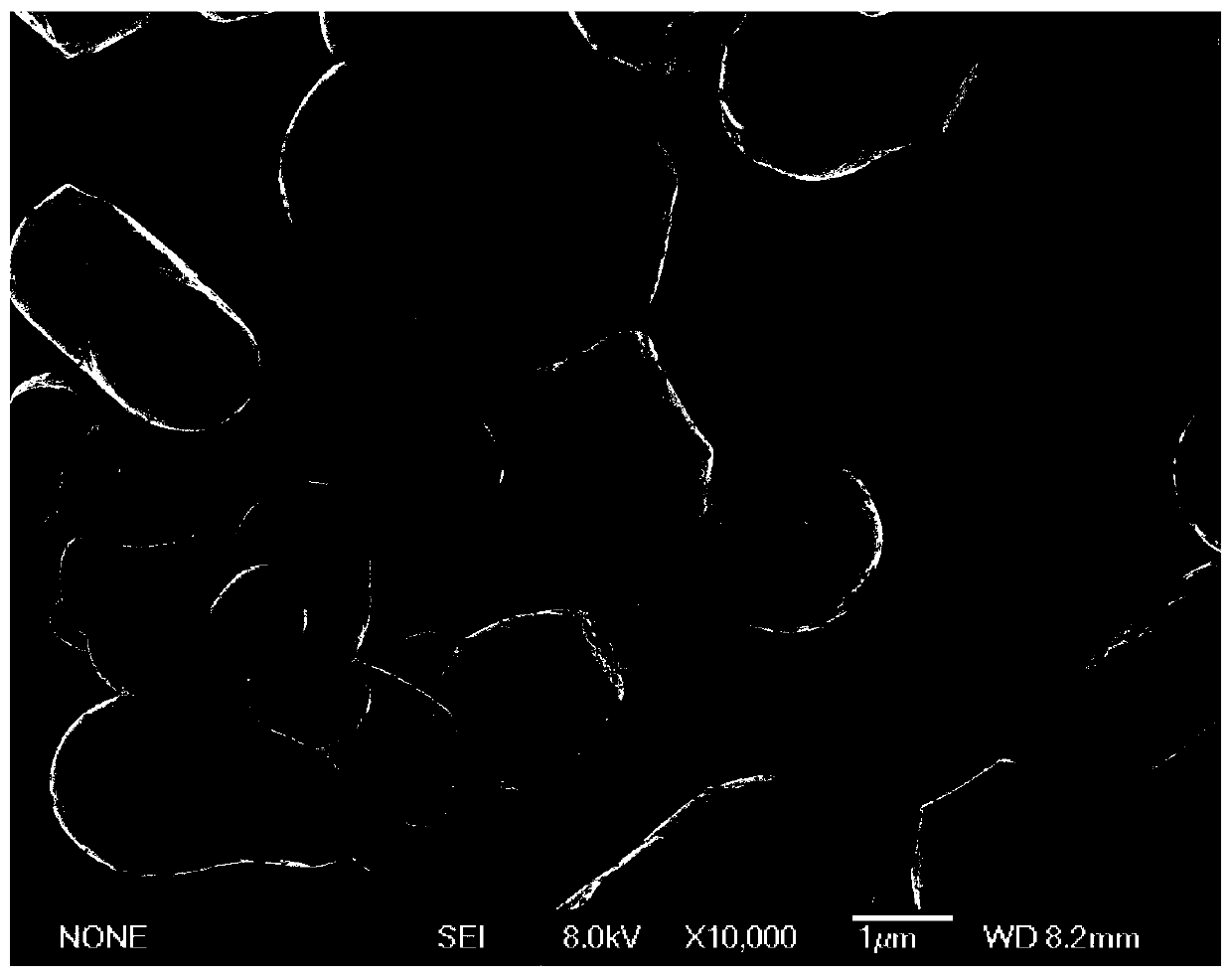

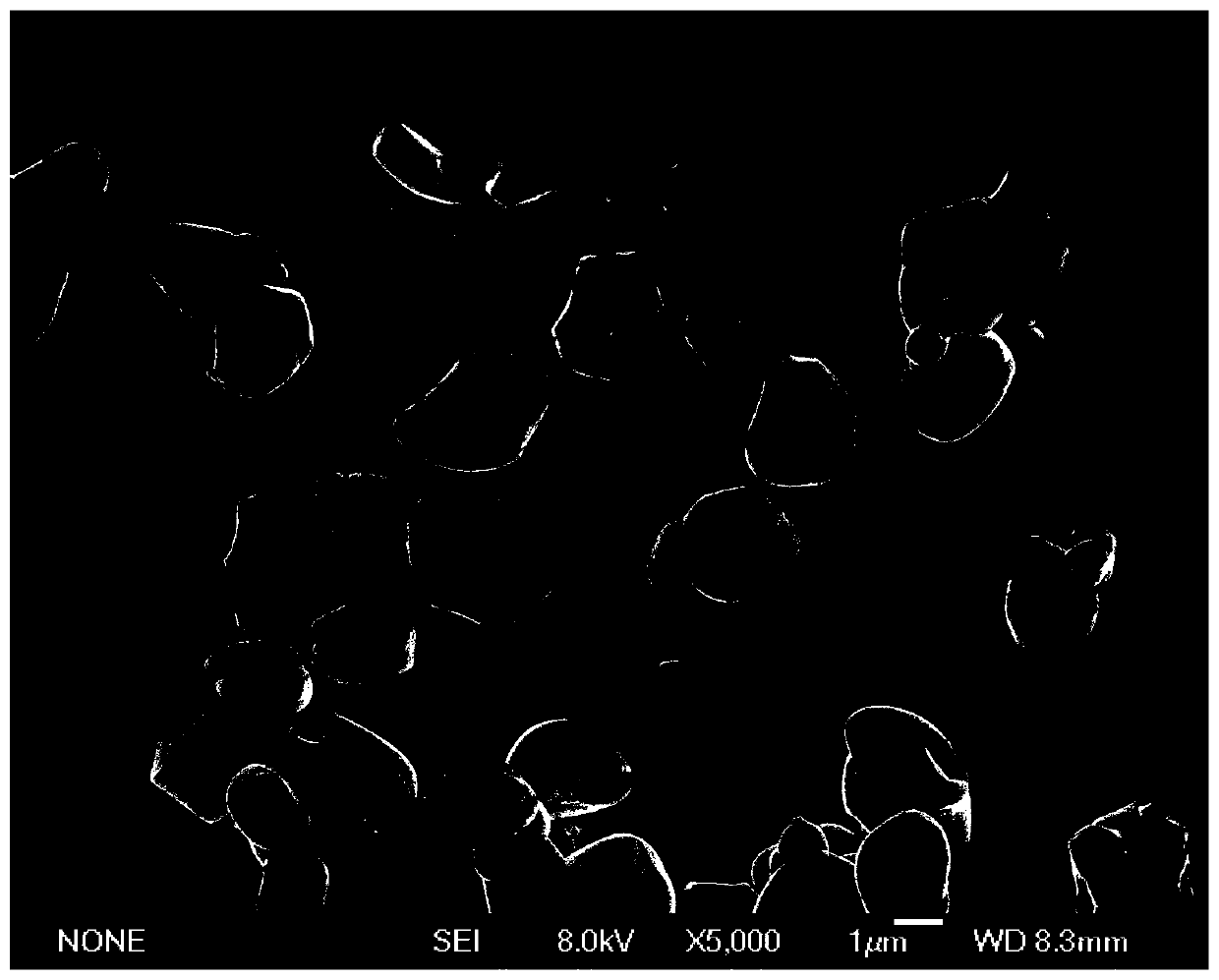

Image

Examples

Embodiment 1

[0030] In step a, soluble nickel sulfate, cobalt sulfate, and manganese sulfate are mixed according to the ratio of the amount of substances in a ratio of 1:1:1, and the mixture is added to a certain amount of pure water to dissolve to obtain a solution; at the same time, a complexing agent and a precipitating agent are added , mixed to obtain a co-precipitate, and the co-precipitate was subjected to solid-liquid separation using a centrifuge to obtain a precursor A;

[0031] Step b, mixing the precursor A with a lithium salt, heating and reacting to form a semi-finished product B;

[0032] Step c, mixing the compound corresponding to the required doping element with the semi-finished product B according to a certain ratio, using a high-mixer to mix evenly, and sintering at a high temperature to obtain the finished product C;

[0033] In step d, the finished product C is mixed with a certain proportion of coating compound, and heat-treated at 550°C for 5 hours to form a coatin...

Embodiment 2

[0045] Step a, mix soluble nickel salt, cobalt salt, and manganese salt according to the ratio of the amount of substances in a ratio of 1:1:1, add the mixture to a certain amount of pure water to dissolve, and obtain a solution; add complexing agent and precipitating agent at the same time , mixed to obtain a co-precipitate, and the co-precipitate was subjected to solid-liquid separation using a centrifuge to obtain a precursor A;

[0046] Step b, mixing the precursor A with a lithium salt, heating and reacting to form a semi-finished product B;

[0047] Step c, mixing the compound corresponding to the required doping element with the semi-finished product B according to a certain ratio, using a high-mixer to mix evenly, and sintering at a high temperature to obtain the finished product C;

[0048] In step d, the finished product C is mixed with a certain proportion of coating compound, and heat-treated at 850°C for 12 hours to form a coating layer on the surface of the sampl...

Embodiment 3

[0061] Step a, mix the soluble nickel salt, cobalt salt, and manganese salt according to the ratio of the amount of the substance at 5:2:3, add the mixture to a certain amount of pure water to dissolve, and obtain a solution; simultaneously add a complexing agent and a precipitating agent , mixed to obtain a co-precipitate, and the co-precipitate was subjected to solid-liquid separation using a centrifuge to obtain a precursor A;

[0062] Step b, mixing the precursor A with a lithium salt, heating and reacting to form a semi-finished product B;

[0063] Step c, mixing the compound corresponding to the required doping element with the semi-finished product B according to a certain ratio, using a high-mixer to mix evenly, and sintering at a high temperature to obtain the finished product C;

[0064] In step d, the finished product C is mixed with a certain proportion of coating compound, and heat-treated at 550°C for 5 hours to form a coating layer on the surface of the sample to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com