Preparation technology of micron-size monocrystalline primary particle ternary cathode material

A technology of cathode material and preparation process, which is applied in the field of preparation technology of micron-sized single crystal primary particle ternary cathode material, can solve the problems of high cost, particle breakage, long time consumption, etc., and achieve easy control, good single crystal form, Good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

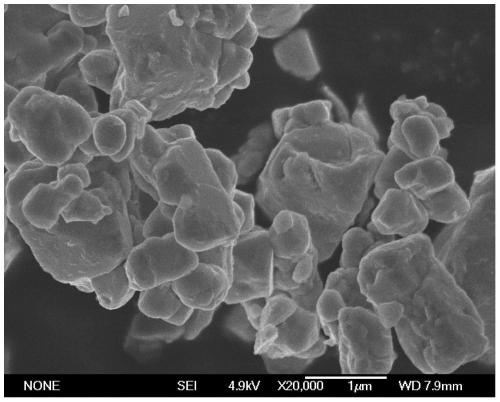

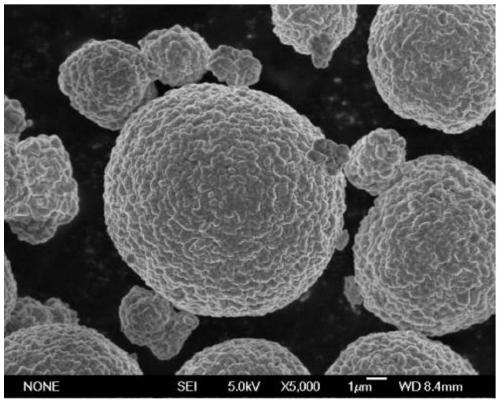

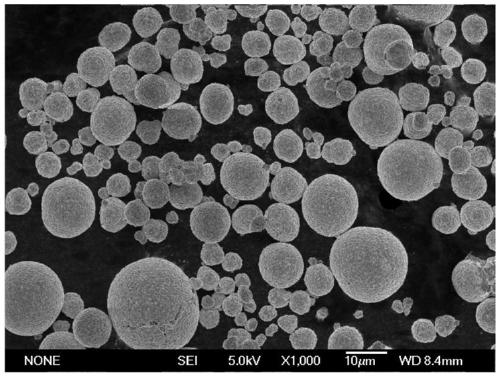

[0017] Mix nickel salt, cobalt salt and manganese salt solution in proportion, add complexing agent ammonia, add precipitant sodium hydroxide, mixing temperature is 50 ° C, pH is 11, after mixing, coprecipitate is obtained, and coprecipitate is centrifuged machine for solid-liquid separation to obtain the precursor Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 ; a small amount of precursor Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 Add lithium salt, mix in a high-speed mixer, and then perform heat treatment. The temperature of the heat treatment is controlled at 600 ° C for 24 hours to obtain small seed crystal particles of 0.2 μm; the prepared small seed crystal particles are mixed with Precursor Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 Mix evenly according to the weight ratio of 1:20, mix with lithium salt at the same time, carry out solid phase reaction, the temperature is controlled at 850 ℃, after reacting for 10 hours, obtain 4.5 μ m single crystal particles.

Embodiment 2

[0019] Mix nickel salt, cobalt salt and manganese salt solution according to the proportion, add complexing agent ammonia, add precipitant sodium hydroxide, mixing temperature is 90 ℃, pH is 11.8, after mixing, a coprecipitate is obtained, and the coprecipitate is centrifuged machine for solid-liquid separation to obtain the precursor Ni 0.5 co 0.2 mn 0.3 (OH) 2 ; a small amount of precursor Ni 0.5 co 0.2 mn 0.3 (OH) 2 Add lithium salt, mix in a high-speed mixer, and then perform heat treatment. The temperature of the heat treatment is controlled at 750 ° C for 25 hours to obtain small seed crystal particles of 1 μm; the prepared small seed crystal particles and the precursor Bulk Ni 0.5 co 0.2 mn 0.3 (OH) 2 Mix evenly according to the weight ratio of 1:10, and at the same time mix with lithium salt, carry out solid state reaction, the temperature is controlled at 900 ° C, after 10 h of reaction to obtain 5.0 μ m single crystal particles.

Embodiment 3

[0021] Mix nickel salt, cobalt salt and aluminum salt solution in proportion, add complexing agent ammonia, add precipitating agent sodium hydroxide, mixing temperature is 70 ° C, pH is 12, after mixing, a coprecipitate is obtained, and the coprecipitate is centrifuged machine for solid-liquid separation to obtain the precursor Ni 0.8 co 0.15 Al 0.05 (OH) 2 ; a small amount of precursor Ni 0.8 co 0.15 Al 0.05 (OH) 2 Add lithium salt, mix in a high-speed mixer, and then perform heat treatment. The temperature of the heat treatment is controlled at 950 ° C for 30 hours to obtain small seed crystal particles of 0.55 μm; the prepared small seed crystal particles are mixed with Precursor Ni 0.8 co 0.15 Al 0.05 (OH) 2 Mix evenly according to the weight ratio of 2:25, mix with lithium salt at the same time, carry out solid phase reaction, the temperature is controlled at 900 ℃, after reacting for 10 hours, obtain 4.8 μ m single crystal particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com