A kind of preparation method of single crystal nickel cobalt lithium manganate ternary material

A technology of nickel cobalt lithium manganate and ternary materials, applied in chemical instruments and methods, nickel compounds, electrical components, etc., can solve problems such as rate performance, poor cycle performance and capacity, and achieve good rate performance, high commercial value, High volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

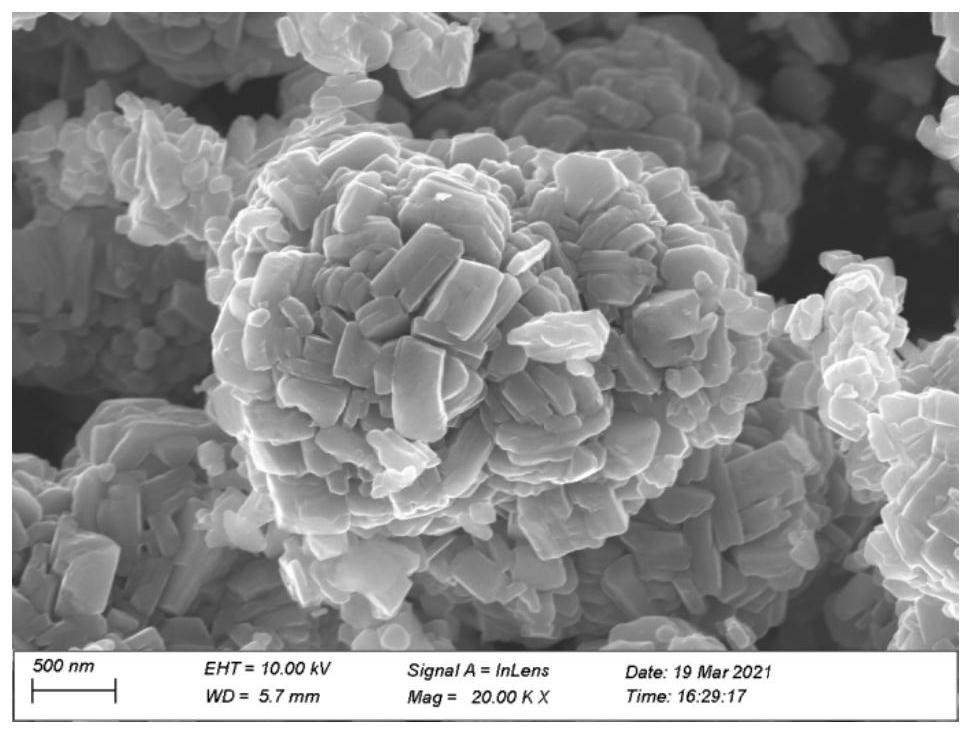

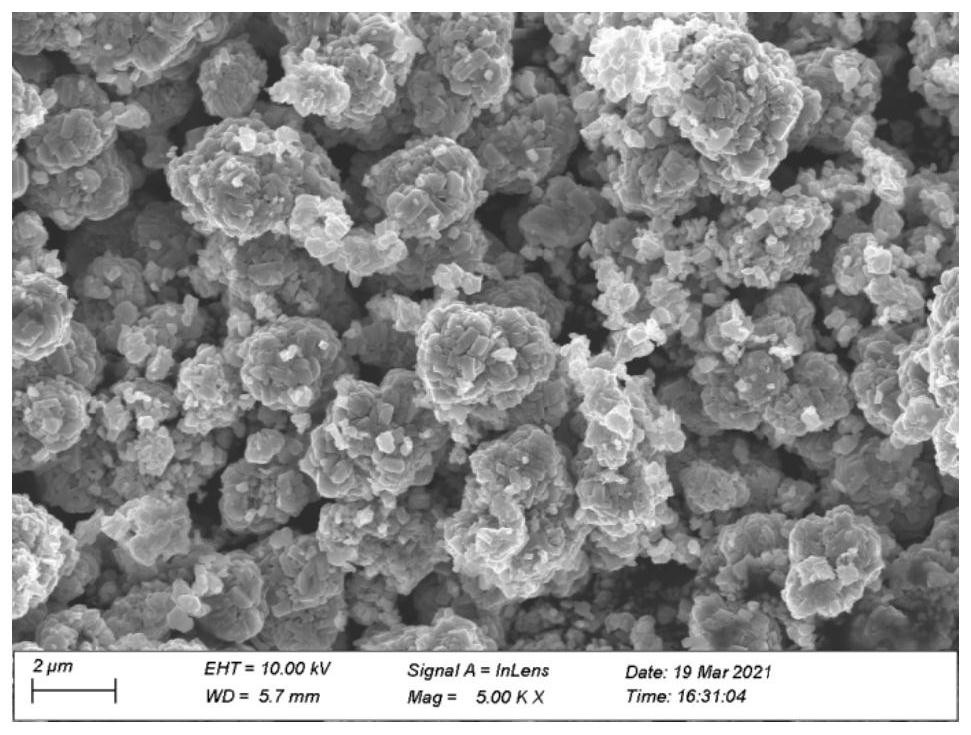

[0034] The invention provides a preparation method of a single crystal nickel cobalt lithium manganate ternary material, the method comprises the following steps:

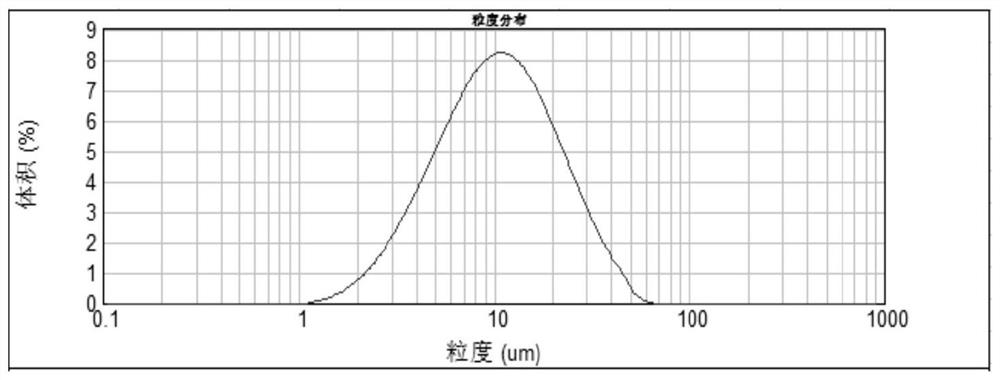

[0035] (1) mixing the lithium source and the ternary single crystal precursor in a mass ratio (0.8-1.2): 1, then heating and calcining to obtain an agglomerate structure seed crystal with a D50 of 9-12 μm;

[0036](2) mixing the agglomerate structure seed obtained in step (1) with a ternary single crystal precursor and a lithium source to obtain a mixture, and then heating and calcining to obtain a single crystal nickel cobalt lithium manganate ternary material;

[0037] Wherein, the ternary single crystal precursor is Ni x Co y Mn z (OH) 2 , 0.5≤x≤1, 0≤y≤0.4, 0≤z≤0.4, x+y+z=1;

[0038] In step (2), the mixture contains 1-5% by weight of aggregate structure seeds;

[0039] In step (2), the ratio of the amount of the lithium element in the lithium source to the total amount of the three elements of nickel, coba...

Embodiment 1

[0060] (1) Lithium carbonate and ternary 523 single crystal precursor Ni 0.5 Co 0.2 Mn 0.3 (OH) 2 Mix evenly with a VC mixer at a mass ratio of 0.8:1, then put the materials into a muffle furnace, and in an air atmosphere, heat up to 700°C for 20h at a heating rate of 5°C / min to obtain agglomerates with a D50 of 10.45μm body structure seed;

[0061] (2) adding the agglomerate structure seed obtained in step (1), the ternary 523 single crystal precursor and lithium carbonate into a high-mixer and mixing uniformly to obtain a mixture, the amount of the lithium element in the lithium carbonate is the same as that of the three The ratio of the total amount of the three elements of nickel, cobalt, and manganese in the Yuan 523 single crystal precursor is 1.08:1, and the mixture contains 1% by weight of agglomerate structure seeds, and then the mixture is put into a muffle furnace. In an air atmosphere, the temperature was raised to 700°C for 3 h at a heating rate of 3°C / min, an...

Embodiment 2

[0063] (1) Lithium carbonate and ternary 523 single crystal precursor Ni 0.5 Co 0.2 Mn 0.3 (OH) 2 Mix evenly with a VC mixer at a mass ratio of 1.2:1, then put the material into a muffle furnace, and in an air atmosphere, raise the temperature to 750°C at a heating rate of 3°C / min for 24 hours, and obtain agglomerates with a D50 of 11.68 μm. body structure seed;

[0064] (2) adding the agglomerate structure seed obtained in step (1), the ternary 523 single crystal precursor and lithium carbonate into a high-mixer and mixing uniformly to obtain a mixture, the amount of the lithium element in the lithium carbonate is the same as that of the three The ratio of the total amount of nickel, cobalt, and manganese in the element 523 single crystal precursor is 1.03:1, and the mixture contains 5% by weight of agglomerate structure seeds, and then the mixture is put into a muffle furnace, and the mixture is placed in a muffle furnace. In an air atmosphere, the temperature was raised...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com