Treatment method for tobacco sheet concentrated solution in papermaking method

A technology of tobacco sheet and processing method, applied in the directions of tobacco, tobacco preparation, tobacco processing, etc., can solve the problems of influence of concentrated liquid quality, low space utilization rate, inconvenient operation, etc., so as to reduce resource waste, economic loss, and weight reduction. , good for heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

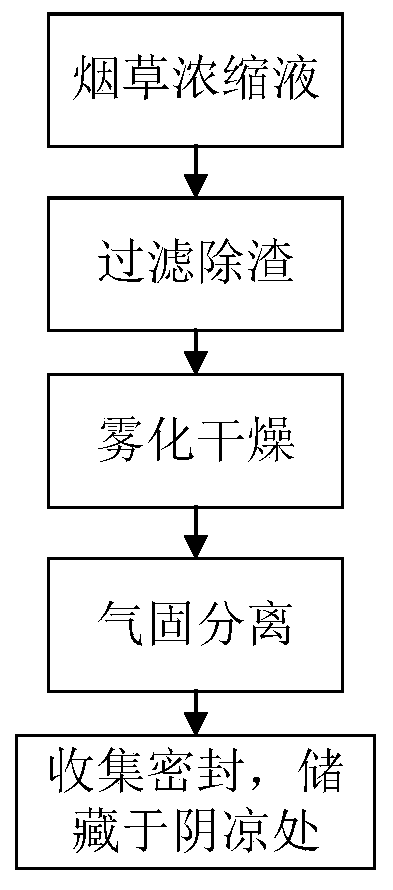

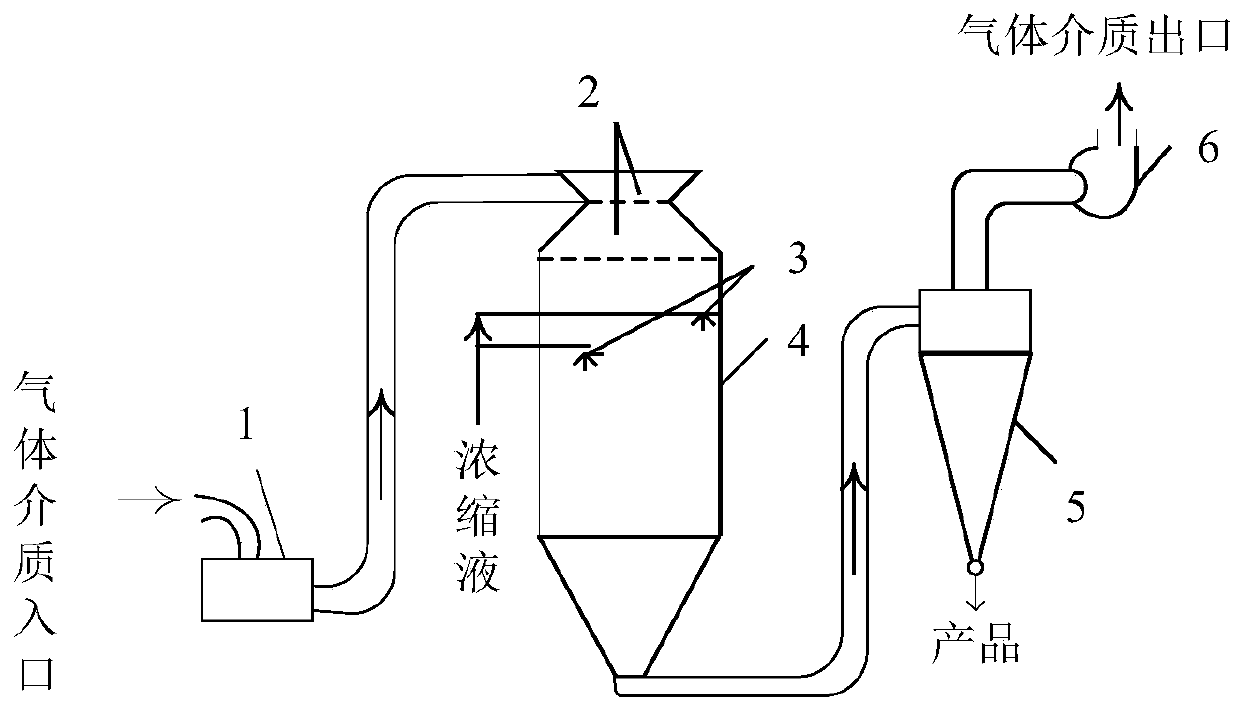

[0027] Such as figure 1 , 2 As shown, it is the process flow chart of the treatment method of the paper-making tobacco thin sheet concentrate, collect 1 ton of surplus concentrate at the end of production, filter and remove the tobacco debris, and form a mist concentrate by the atomizer nozzle 3 through the atomizer Fine droplets, dispersed in the heated gas medium, the gas medium is heated by the heating furnace 1 and passed through the top of the drying tower 4, and the heated flowing gas medium makes the water vapor in the concentrated liquid rapidly atomized, The dried solid matter enters the cyclone separator 5 with the gas to realize gas-solid separation. The solid matter is discharged from the discharge butterfly valve installed at the bottom of the cyclone separator, and the gas is sucked away by the fan 6 at the top of the cyclone separator 5. Store solid matter in a cool place after collection. Preferably, the hot air temperature at the inlet of the drying tower 4 ...

Embodiment 2

[0029] Such as figure 1 , 2 As shown, it is the process flow chart of the treatment method of tobacco sheet concentrate by papermaking method. Collect 1 ton of surplus concentrate at the end of production, filter and remove tobacco debris, form mist concentrate droplets through a sprayer, and disperse them in the heated In the gas medium, the water vapor in the concentrated liquid is quickly atomized, and the dried solid matter enters the cyclone separator 5 with the gas to achieve gas-solid separation, and finally discharged from the discharge butterfly valve, collected and stored in a cool place. The hot air temperature at the inlet of the drying tower 4 is 220°C, the atomizer is a rotary atomizer with a rotating speed of 10000r / min, and the wind speed inside the drying tower 4 is 0.15m / s. After 30 days, take out the stored solid powder and dissolve it in 45°C warm water to form 1 ton of concentrated solution. Its odor does not change after observation, and its viscosity is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com