Chuanxiong rhizome oil microcapsule and preparation method thereof, and chuanxiong rhizome oil microcapsule gel patch and preparation method thereof

A technology of microcapsule gel patch and Ligusticum chuanxiong oil, which is applied in the field of medicine, can solve the problems of thermal instability, easy volatilization, and easy oxidation, and achieve the effects of improving stability, no skin irritation, and high encapsulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In this example, the effects of different concentrations of gelatin aqueous solution on the properties of Chuanxiong oil microcapsules were investigated. The preparation method of the Chuanxiong oil microcapsules of this embodiment is specifically:

[0060] Step 1. Accurately weigh gelatin and gum arabic respectively, pipette 100ml of pure water, ultrasonicate for 30 minutes, and then bathe in water at 50°C for 30 minutes to completely dissolve gelatin and gum arabic to obtain gelatin aqueous solution and gum arabic aqueous solution;

[0061] Step 2. Add 1.0g Chuanxiong oil to the aqueous gelatin solution, and emulsify at 18000rpm for 5min to obtain a gelatin-Chuanxiong oil emulsion;

[0062] Step 3. Slowly add an aqueous solution of gum arabic to the gelatin-Chuanxiong oil emulsion, wait for the temperature of the solution to rise to 50°C, and stir it magnetically for 1 hour; then add twice the volume of the mixed solution of pure water at 50°C to reduce the viscosity ...

Embodiment 2

[0082] This embodiment investigates the impact of different concentrations of gum arabic aqueous solution on the properties of microcapsules, specifically:

[0083] Accurately weigh 1, 2, 2.5, 3, 4, 5g gum arabic gum respectively, add 100ml pure water, obtain 1%, 2%, 2.5%, 3%, 4%, 5% gum arabic solution, gelatin solution 3.0%. The microcapsules were prepared according to the method of Example 1, and other parameters were kept constant, and the influence of different gum arabic solution concentrations on the properties of the microcapsules was investigated. The results are shown in Table 2:

[0084] Table 2 Effects of Gum Arabic Solution with Different Concentrations on the Properties of Microcapsules

[0085] concentration 1% 2% 2.5% 3% 4% 5% Encapsulation rate (%) 41.06 42.11 75.23 80.11 - - Drug loading(%) 15.22 12.56 13.75 27.47 - - Sedimentation rate (%) 56.49 76.74 78.01 83.56 - -

[0086] It can be seen from the abo...

Embodiment 3

[0088] In this example, the influence of different emulsification rotational speeds on the properties of microcapsules is investigated, specifically:

[0089] Prepare microcapsules according to the method of Example 1, wherein in step 1, the mass concentration of the gelatin aqueous solution and the gum arabic aqueous solution are both set to 3%, and the emulsification speed is set to 12000, 15000, 18000 rpm respectively, and other parameters remain unchanged. Observe the emulsification speed Effect on Microcapsule Morphology. The results are shown in Table 3:

[0090] Table 3 Effect of emulsification rotation speed on properties of microcapsules

[0091]

[0092]

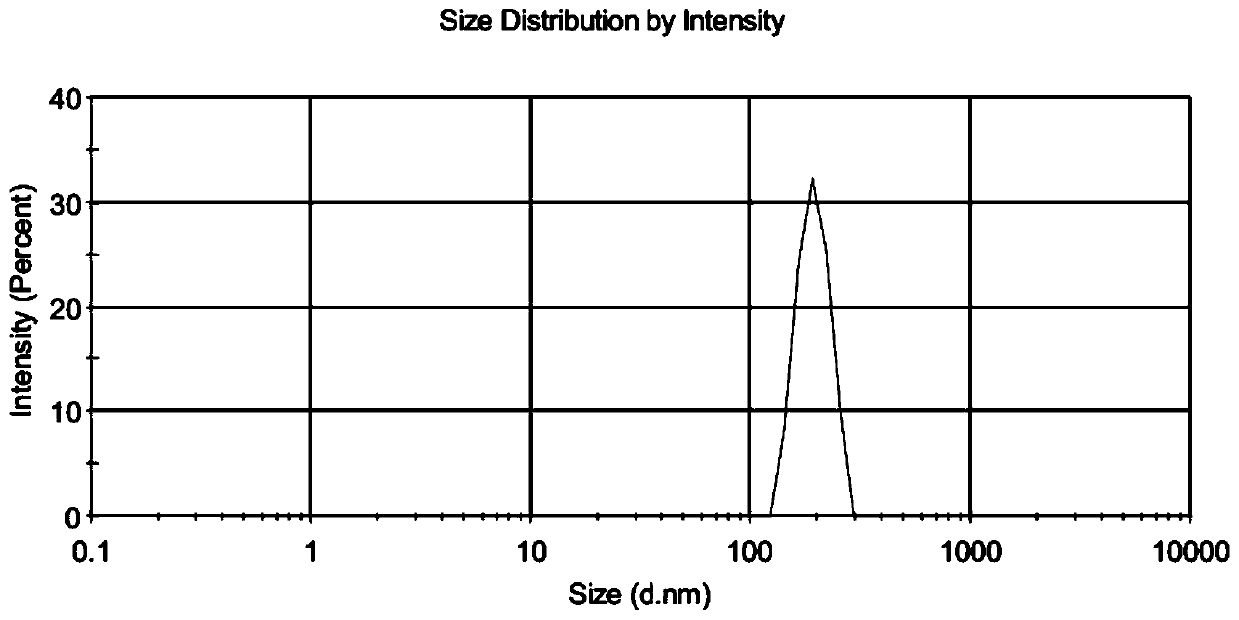

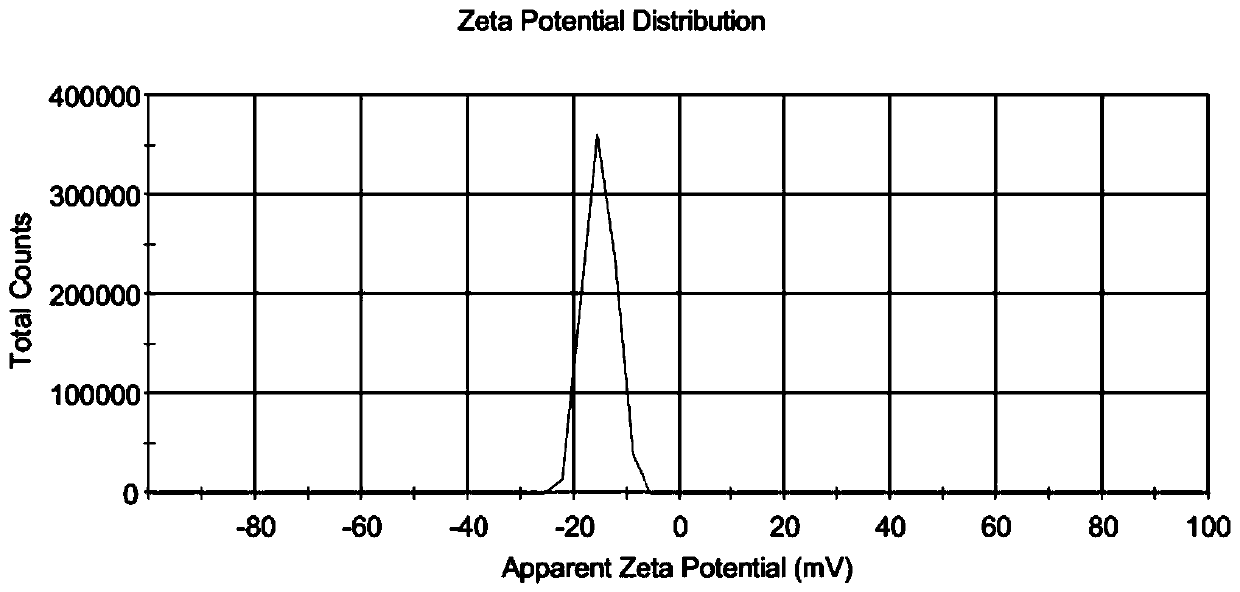

[0093] It can be seen from the experimental results that the rotational speed has little effect on the microencapsulation efficiency, and the particle size does not decrease with the increase of the emulsification rotational speed, which may be related to the electrostatic interaction between the gelatin-chu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com