A cold processing technology of ultra-deep hole slender parts and cold extrusion elongation die

An ultra-deep hole and cold extrusion technology, applied in the direction of metal extrusion dies, etc., can solve the problems of difficulty in forming ultra-deep hole slender parts, high difficulty in cold heading, and low processing efficiency, so as to improve processing efficiency and Excellent processing quality, various mechanical properties, and strong processing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

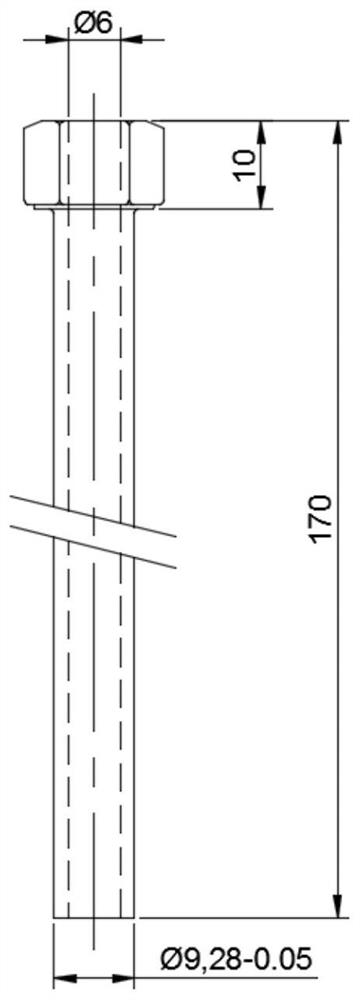

[0060] like figure 1 As shown, it is a hollow suspender for performing a bicycle handle, its total length is 170 mm, the diameter of the central through hole is 6 mm, the outer diameter of the rod is about 9.28 mm, and it also has an outer hexagonal head at the end. The length-to-diameter ratio of the hollow boom reaches 28 times, which belongs to the "ultra-deep hole", and it is difficult to make this part by traditional cold extrusion process.

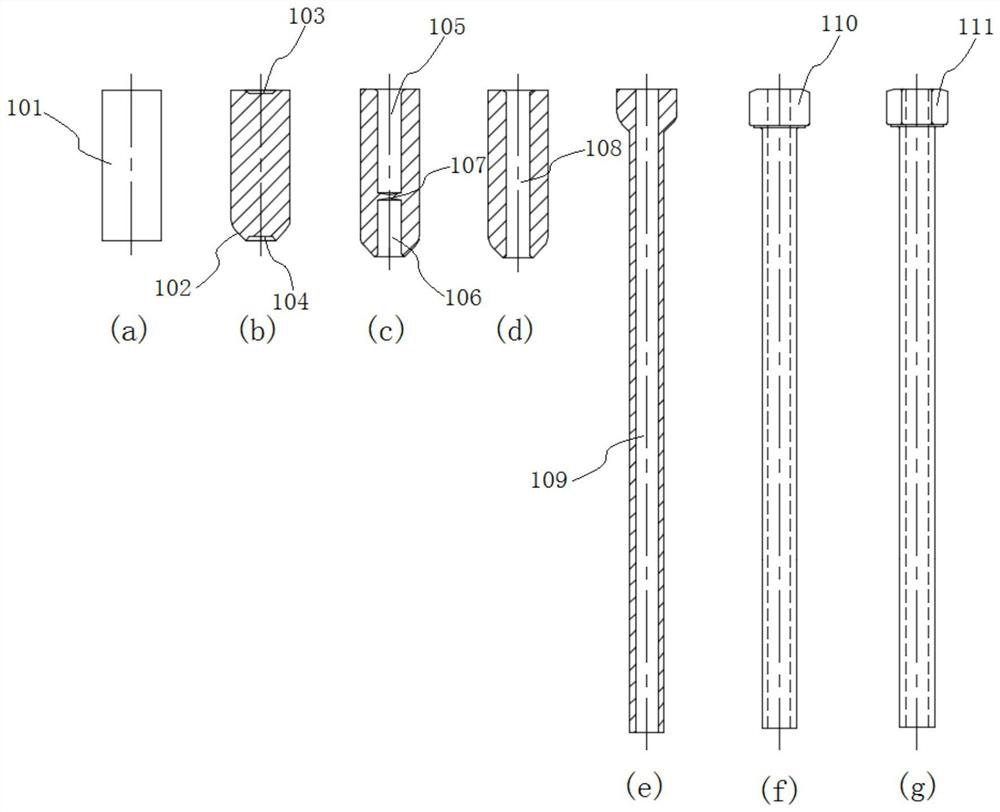

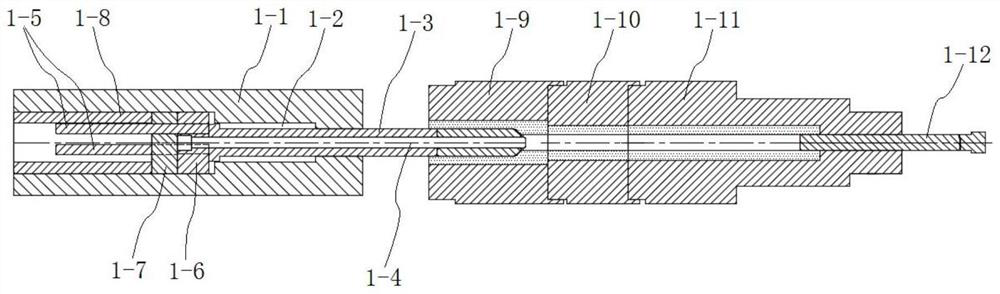

[0061] like figure 2 As shown, the cold working process of an ultra-deep hole slender part in this embodiment is formed by cold extrusion with a multi-station cold heading machine, which first forms a central through hole 108 on the bar 101 to form a hollow short tube blank Then utilize the grommet to stretch into the central through hole 108 of the hollow short tube blank, under the protection of the grommet, the hollow short tube blank is cold extruded and stretched to the required length of the part, and the ultra-thin part is f...

Embodiment 2

[0076] like Figure 4 As shown, it is a hollow piston rod blank for an electric bicycle shock absorber, its total length is 122mm, the diameter of the upper long hole is 9mm, the diameter of the lower necking hole 112 is 6.9mm, and the length is 15mm. The diameter is 12mm, and it also has a hexagon socket head 113 at the end. The length-to-diameter ratio of the hollow piston rod is more than 10 times, which belongs to the "ultra-deep hole". The traditional cold extrusion process is difficult and inefficient.

[0077] like Figure 5 As shown, the cold working process of an ultra-deep hole slender part in this embodiment adopts a multi-station cold heading machine for cold extrusion molding. It first performs surface phosphating treatment on the bar 101 according to the needs of the part. After the bar 101 The central through hole 108 is formed on the top to form a hollow short tube blank; then the center through hole 108 of the hollow short tube blank is inserted into the hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com