Egg white protein-carrageenan composite film and preparation method and application thereof

A technology of egg white protein and carrageenan, applied in the field of packaging materials, can solve the problems of unreported research on film-forming mechanism, poor heat-sealing performance, low mechanical strength, etc., and achieves optimization of preparation process parameters, excellent performance, and operability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the content of the present invention easier to understand, the technical solutions of the present invention will be further described below in conjunction with specific embodiments, but the present invention is not limited thereto.

[0018] Sample Preparation

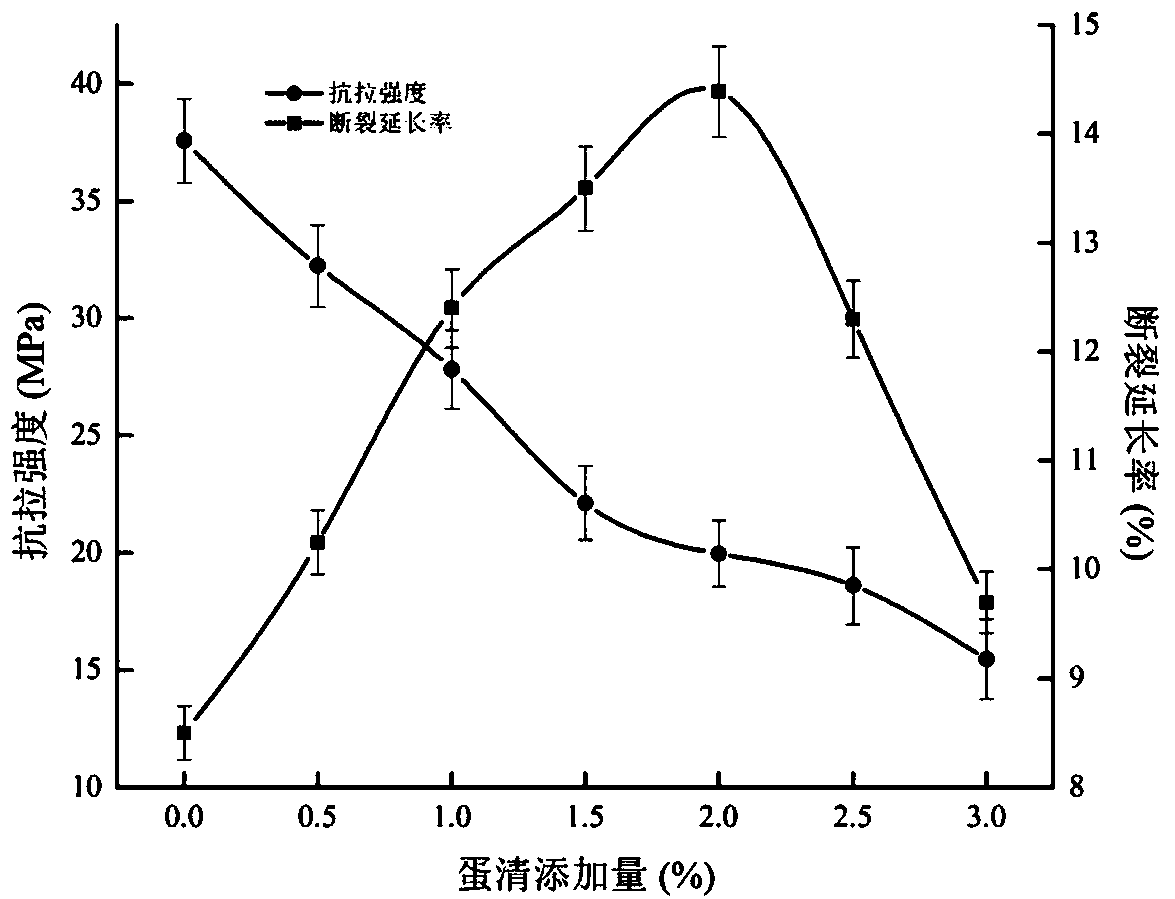

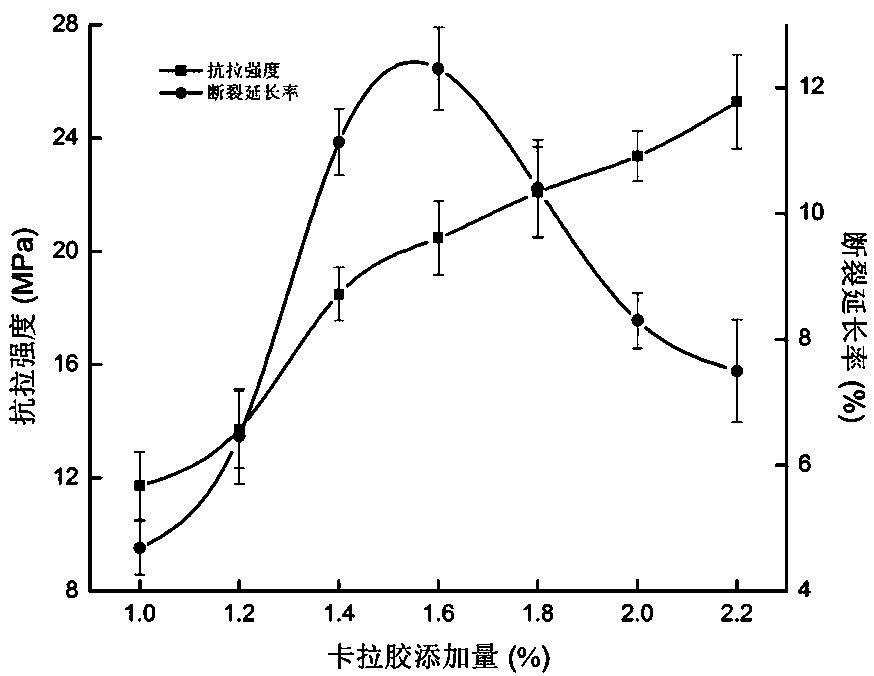

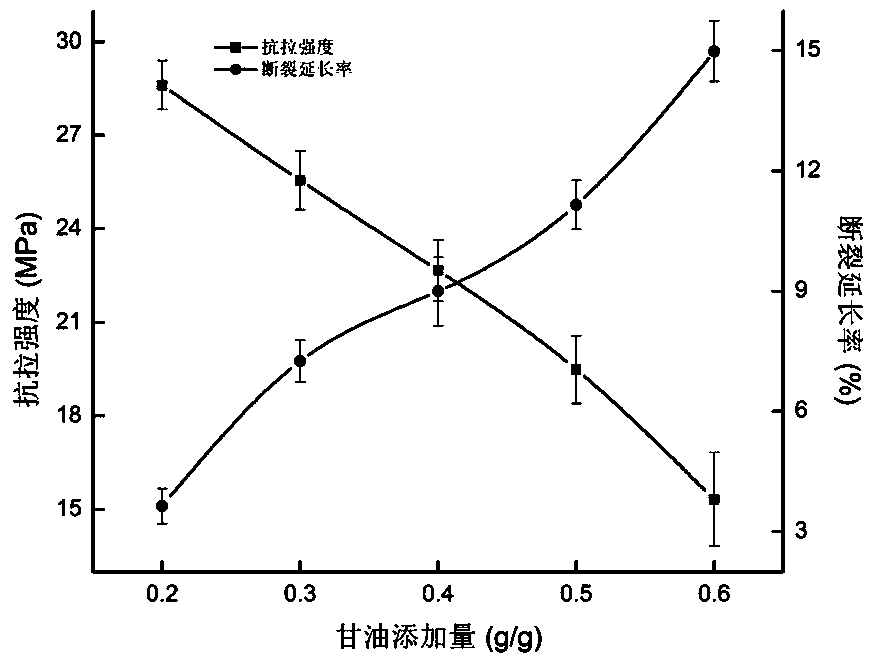

[0019] Preparation of egg white protein-carrageenan composite film

[0020] Will kappa -Add carrageenan to hot water at 40°C, stir until there are no bubbles, add egg white protein powder and glycerin, adjust the total volume of the film-forming solution to 60 mL with deionized water, adjust the pH value (0.1 mol / L NaOH solution) and The solution was stirred evenly, heated in a water bath at 60°C for 30 min, and degassed by ultrasonic for 10 min. After the film-forming solution was stirred slowly, 13 mL of the film-forming solution was poured into a plastic petri dish, cooled at room temperature for 1 h, and then placed in an oven at 40°C. Dry to constant film weight. The film to be tested was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com