A room temperature curing epoxy potting adhesive used under warm and shock environment conditions and preparation method thereof

A technology that cures under ambient conditions and at room temperature. It is applied in the field of potting adhesives, which can solve problems such as easy cracking and debonding, and achieve good process performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

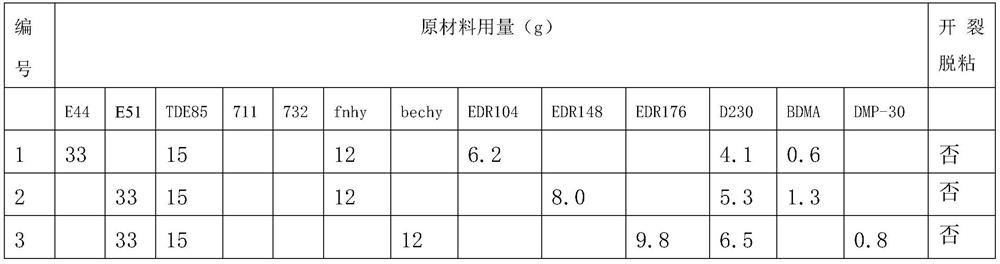

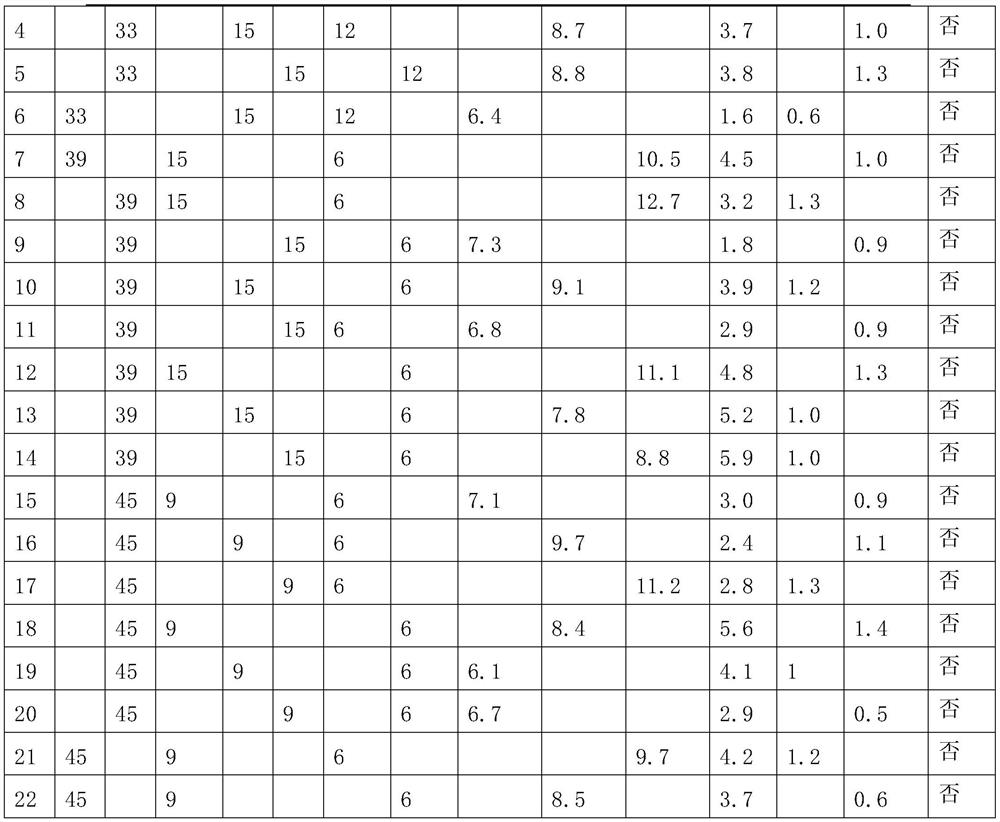

Embodiment 1

[0041] An epoxy potting adhesive that cures at room temperature and is used under warm and shock environment conditions, including: 33g epoxy resin E44, 15g 4,5-epoxycyclohexane-1,2-diglycidyl dicarboxylate TDE-85, 12g tetrahydrofuran polyether epoxy (fnhy), 6.2g dibasic polyetheramine EDR104, 4.1g dibasic polyetheramine D230 and 0.6g benzyldiamine (BDMA).

[0042] This example also provides a preparation method for the above-mentioned epoxy potting glue that is cured at room temperature and used under warm-shock environment conditions. Potting compound.

Embodiment 2

[0044] An epoxy potting adhesive that cures at room temperature and is used under warm and shock environment conditions, including: 33g epoxy resin E51, 15g 4,5-epoxycyclohexane-1,2-diglycidyl dicarboxylate TDE-85, 12g tetrahydrofuran polyether epoxy (fnhy), 8.0g dibasic polyetheramine EDR148, 5.3g dibasic polyetheramine D230 and 1.3g benzyldiamine (BDMA).

[0045] This example also provides a preparation method for the above-mentioned epoxy potting glue that is cured at room temperature and used under warm-shock environment conditions. Potting compound.

Embodiment 3

[0047] An epoxy potting adhesive that cures at room temperature and is used under warm and shock environment conditions, including: 33g epoxy resin E51, 15g 4,5-epoxycyclohexane-1,2-diglycidyl dicarboxylate TDE-85, 12g polypropylene glycol diglycidyl ether (bechy), 9.8g dibasic polyetheramine EDR176, 6.5g dibasic polyetheramine D230 and 0.8g 2,4,5-tris(dimethylaminomethyl)phenol ( DMP-30).

[0048] This example also provides a preparation method for the above-mentioned epoxy potting glue that is cured at room temperature and used under warm-shock environment conditions. Potting compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com