Preparation method of superhydrophobic porous fibers with oriented pore structure, superhydrophobic porous fibers with oriented pore structure and application thereof

A porous fiber and super-hydrophobic technology, which is applied in the field of preparation of super-hydrophobic porous fibers, can solve the problems of limiting the application of porous fibers, unable to achieve continuous large-scale preparation, and not having super-hydrophobic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] (1) Cut 4.5g of natural cocoons, boil and dry in 1% sodium carbonate solution, dissolve in 20ml of 9mol / ml lithium bromide solution, and dialyze for 24h to prepare a 22.5% silk protein solution.

[0089] Dissolve 0.5 g of chitosan powder in 10 ml of 1% acetic acid solution, stir for 30 min at a speed of 800 rpm / min to make it evenly mixed, and prepare a chitosan solution with a concentration of 50 mg / ml.

[0090] Mix 20ml of silk protein solution and 10ml of chitosan solution evenly, and centrifuge to remove air bubbles to obtain a homogeneous solution, wherein the mass ratio of silk protein to chitosan is 9:1.

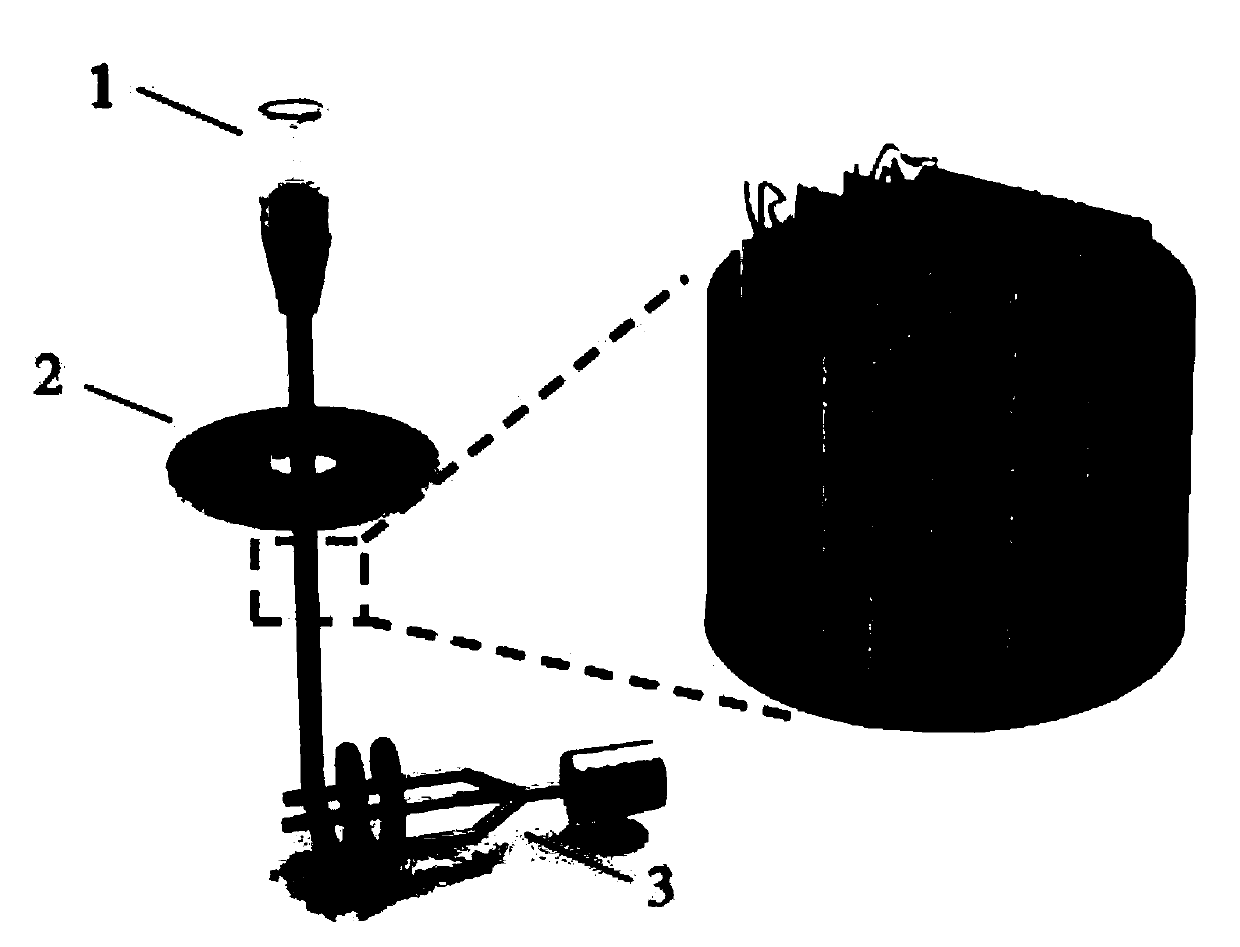

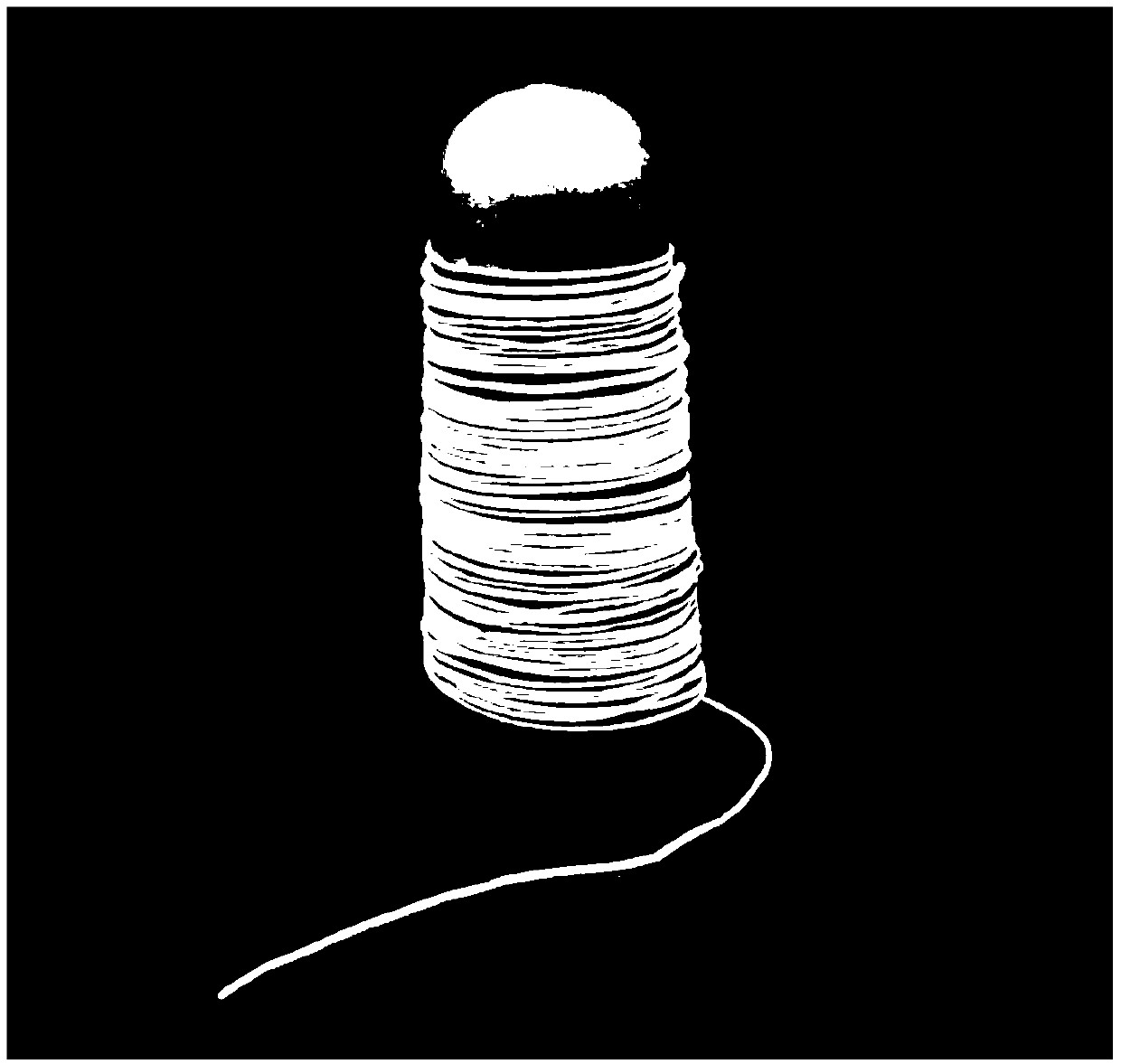

[0091] (2) Put the mixed solution in the syringe, extrude the solution through the extrusion pump, place the copper ring in a low-temperature reaction bath (-100°C), and pass the solution through the copper ring for freezing-spinning process, and the frozen The fibers are collected with a motor.

[0092] (3) Freeze-dry the frozen fiber obtained in step (2) for...

Embodiment 2

[0096] (1) Cut 4.5g of natural cocoons, boil and dry in 1% sodium carbonate solution, dissolve in 20ml of 9mol / ml lithium bromide solution, and dialyze for 24h to prepare a 22.5% silk protein solution.

[0097]Dissolve 0.5 g of chitosan powder in 10 ml of 1% acetic acid solution, stir for 30 min at a speed of 800 rpm / min to make it evenly mixed, and prepare a chitosan solution with a concentration of 50 mg / ml.

[0098] After mixing 20ml of silk protein solution and 10ml of chitosan solution evenly, centrifuge to remove air bubbles to obtain a homogeneous solution, wherein the mass ratio of silk protein to chitosan is 9:1.

[0099] (2) Put the mixed solution in the syringe, extrude the solution through the extrusion pump, place the copper ring in a low temperature reaction bath (-40, -60, -80, -100°C respectively), and pass the solution through the copper ring Freezing-spinning process, and the frozen fibers are collected by motor.

Embodiment 3

[0105] (1) Cut 4.5g of natural cocoons, boil and dry in 1% sodium carbonate solution, dissolve in 20ml of 9mol / ml lithium bromide solution, and dialyze for 24h to prepare a 22.5% silk protein solution.

[0106] Dissolve 0.5 g of chitosan powder in 10 ml of 1% acetic acid solution, stir for 30 min at a speed of 800 rpm / min to make it evenly mixed, and prepare a chitosan solution with a concentration of 50 mg / ml.

[0107] After mixing 20ml of silk protein solution and 10ml of chitosan solution evenly, centrifuge to remove air bubbles to obtain a homogeneous solution, wherein the mass ratio of silk protein to chitosan is 9:1.

[0108] (2) Put the mixed solution in the syringe, extrude the solution through the extrusion pump, place the copper ring in a low-temperature reaction bath (the temperature is -100°C), pass the solution through the copper ring for freezing-spinning process, and freeze The final fiber is collected by motor.

[0109] (3) Freeze-drying the frozen fiber obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com