Preparation method of waterproof breathable blended cloth

A waterproof, breathable, mixed-liquid technology, used in textiles, textiles, papermaking, fabrics, etc., can solve problems such as affecting the service life of textile fabrics, unsuitable for re-wearing, and loss of breathability of textile fabrics. The effect of reducing contact and preventing moisture loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

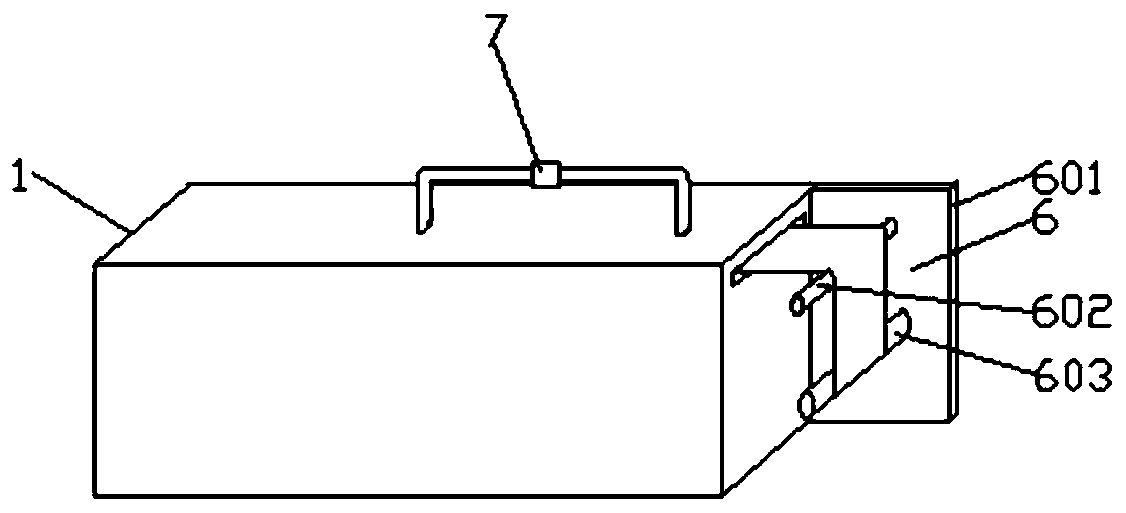

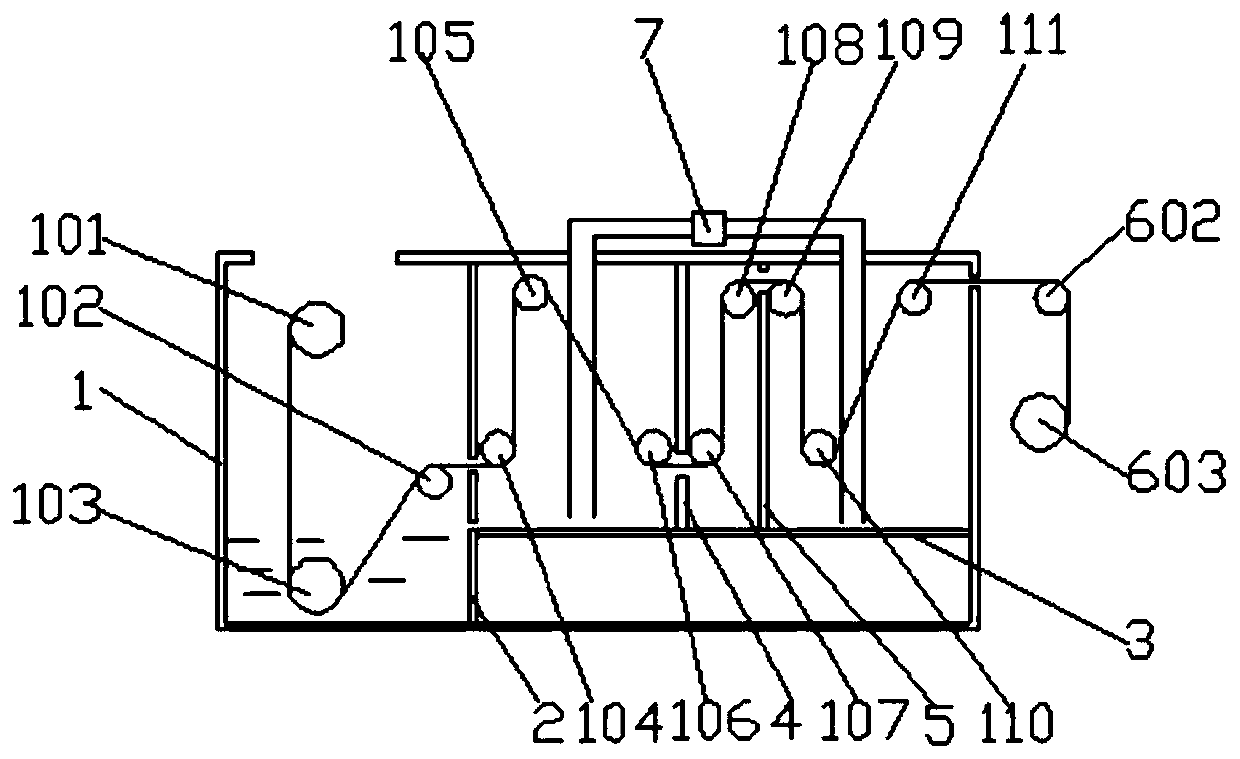

Image

Examples

Embodiment 1

[0038] The invention provides a method for preparing a waterproof and breathable blended fabric, comprising the following steps:

[0039] S1. Take 50 parts by weight of bamboo, 32 parts by weight of reed, 24 parts by weight of hemp, 20 parts by weight of straw, and 28 parts by weight of apocynum, wash, dry, and pulverize to obtain a pulverized product, and place the pulverized product in 300 Cooking at a temperature of 140°C for 50 minutes in a sodium hydroxide solution with a mass fraction of 20% by weight to obtain a cooking liquid;

[0040] S2. Add 60 parts by weight of cassava powder, 34 parts by weight of mulberry leaf powder, and 20 parts by weight of lemon leaf powder to the cooking liquid, stir evenly, then place it at 80° C. for 40 minutes and filter it, then place it in a vibration screening machine Rough selection, extraction by vacuum washing machine, and fine selection by pressure screening machine to obtain coarse slurry;

[0041] S3. Concentrate the coarse slur...

Embodiment 2

[0045] The invention provides a method for preparing a waterproof and breathable blended fabric, comprising the following steps:

[0046] S1. Take 78 parts by weight of bamboo, 40 parts by weight of reed, 28 parts by weight of hemp, 26 parts by weight of straw, and 35 parts by weight of apocynum, wash, dry, and pulverize to obtain a pulverized product, and place the pulverized product in 450 Cooking at a temperature of 160°C for 72 minutes in a sodium hydroxide solution with a mass fraction of 30% by weight to obtain a cooking liquid;

[0047] S2. Add 80 parts by weight of cassava powder, 42 parts by weight of mulberry leaf powder, and 30 parts by weight of lemon leaf powder to the cooking liquid, stir evenly, then place it at 120° C. for 65 minutes and filter it, then place it in a vibration screening machine Rough selection, extraction by vacuum washing machine, and fine selection by pressure screening machine to obtain coarse slurry;

[0048] S3. Concentrate the coarse slu...

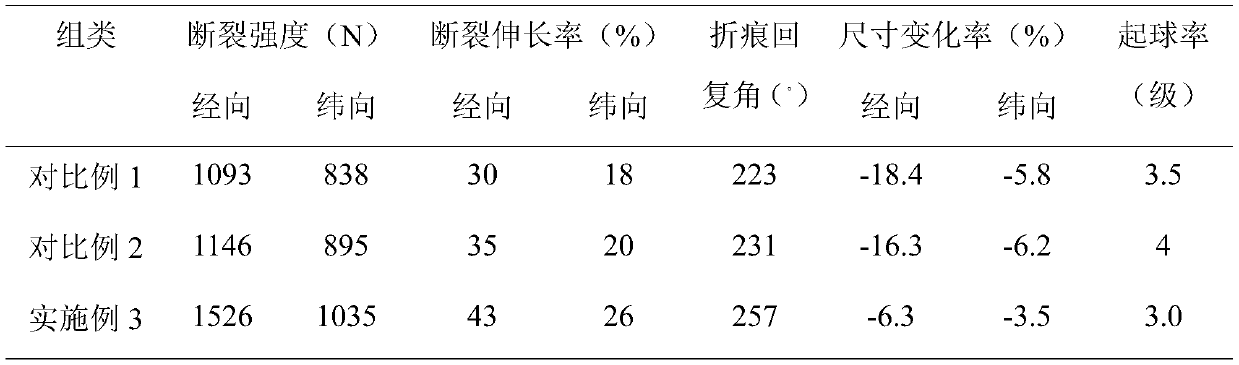

Embodiment 3

[0052] The invention provides a method for preparing a waterproof and breathable blended fabric, comprising the following steps:

[0053] S1. Take 64 parts by weight of bamboo, 36 parts by weight of reed, 26 parts by weight of hemp, 23 parts by weight of straw, and 30 parts by weight of apocynum, wash, dry, and pulverize to obtain a pulverized product, and place the pulverized product in 375 Cooking at a temperature of 150°C for 66 minutes in a sodium hydroxide solution with a mass fraction of 25% by weight to obtain a cooking liquid;

[0054] S2. Add 70 parts by weight of cassava powder, 38 parts by weight of mulberry leaf powder, and 25 parts by weight of lemon leaf powder to the cooking liquid, stir evenly, then place it at 100° C. for 52 minutes and filter it, then place it in a vibration screening machine Rough selection, extraction by vacuum washing machine, and fine selection by pressure screening machine to obtain coarse slurry;

[0055] S3. Concentrate the coarse slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com