Machine-mounted splitting machine

A technology of splitting machine and bearing frame, which is applied in the direction of discharging machinery, earth-moving drilling and mining, etc., can solve the problems of cracking of skin cracks, reducing oil pressure, and inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

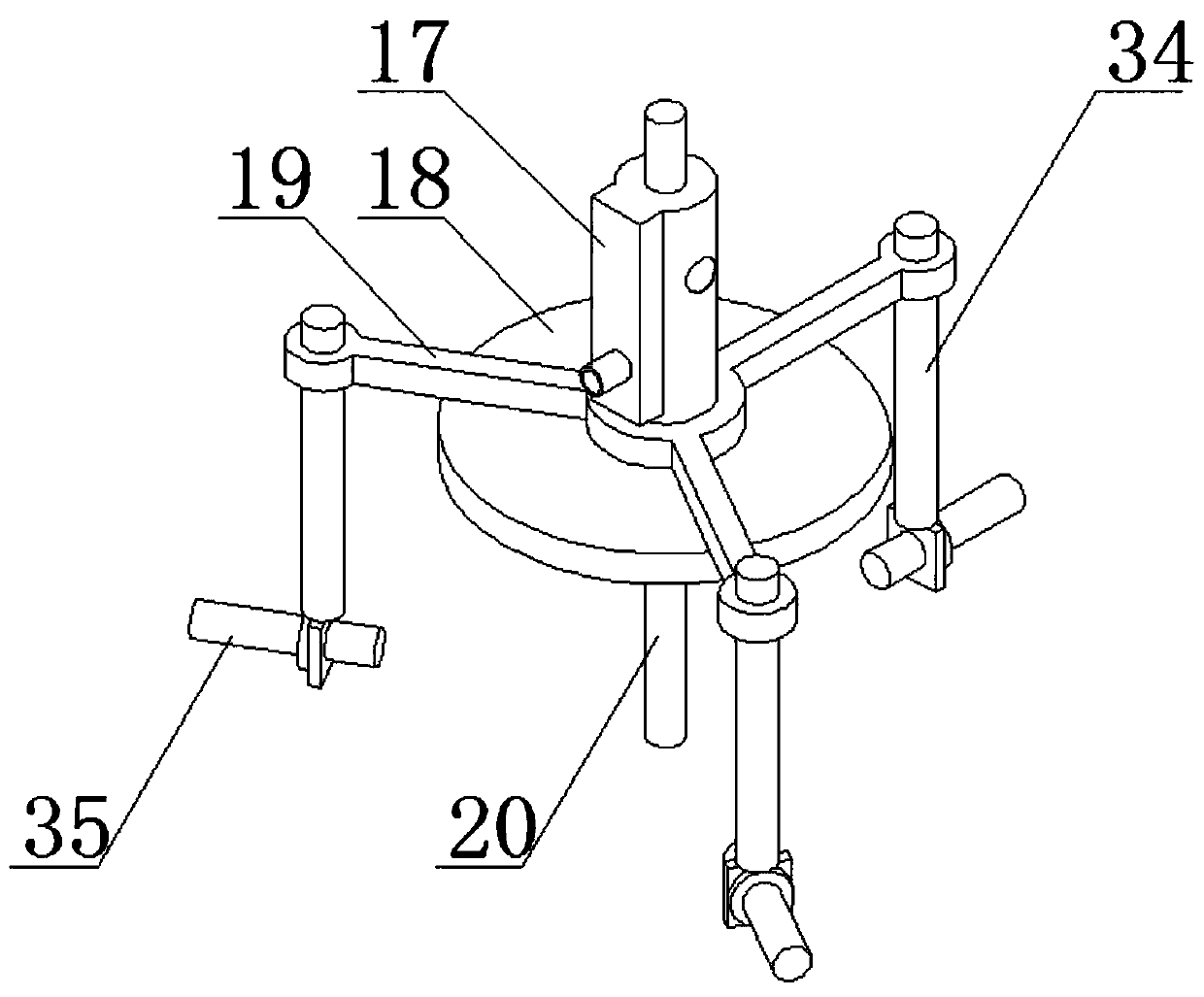

[0027] As a preferred embodiment of the present invention, a surrounding coil 37 is provided in the electromagnet disk 18.

[0028] As a preferred embodiment of the present invention, the magnetic induction coil 22 is connected to the high-power capacitor 6 and the virtual cathode tube 23 through a wire, and the virtual cathode tube 23 is connected to the microwave transmitting antenna 29 through a wire.

[0029] As a preferred embodiment of the present invention, the central splitting head 20 and the lateral splitting head 35 have the same size and specifications.

[0030] As a preferred embodiment of the present invention, the control button includes a start button, a weak magnetic flux button one, a weak magnetic flux button two, a displacement button, a center split button and a horizontal split button, and the control button is connected to The driving motor, the movable oil cylinder 16, the magnetic induction coil 22, the surrounding coil 37 and the igniter 25 are connected, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com