A hanging assembly line control method and system

A control method and control system technology, which is applied in the field of hanging conveyor lines, can solve the problems of complex structure of the control system, high requirements for installation accuracy, and slow data transmission speed, so as to achieve simple system structure, ensure accuracy, and ensure data transmission. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with specific embodiments.

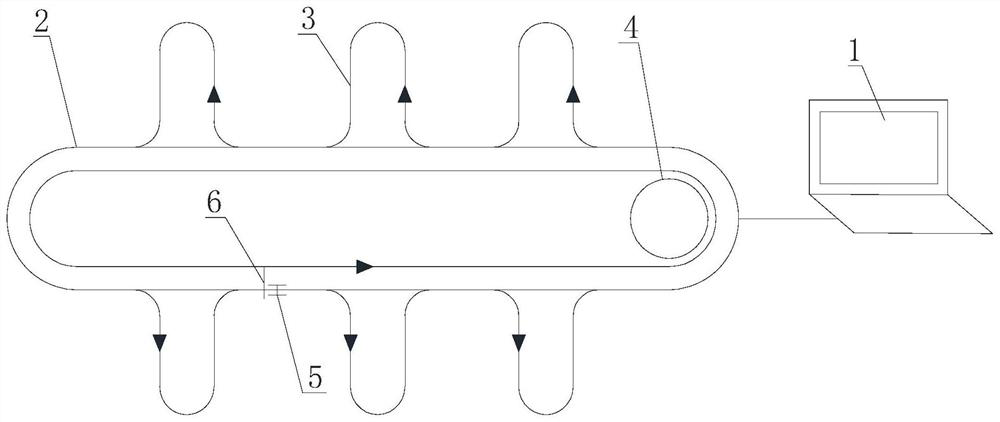

[0046] like figure 1 As shown, the hanging assembly line control system of the present invention mainly includes a main computer 1, a main rail 2, at least two or more workstations 3, a driving mechanism 4, and a clothes hanger 5 is hung on the main rail 2. The workstation 3 is distributed on the outside of the main rail 2, and the top of the main rail 2 is provided with push rods 6 distributed at a certain interval. The push rods 6 are driven by the driving mechanism 4 to push the clothes hangers 5 on the main rail 2 to run in a specified direction. RFID chips are all installed on the push rod 6 and the clothes hanger 5 .

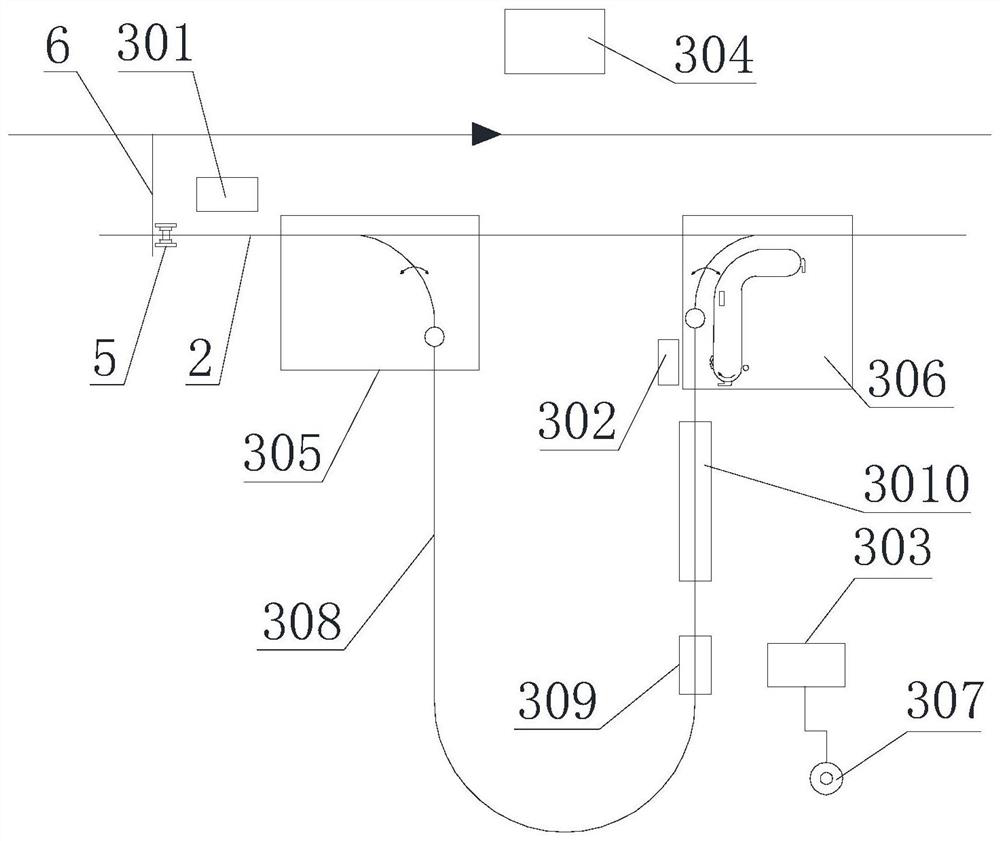

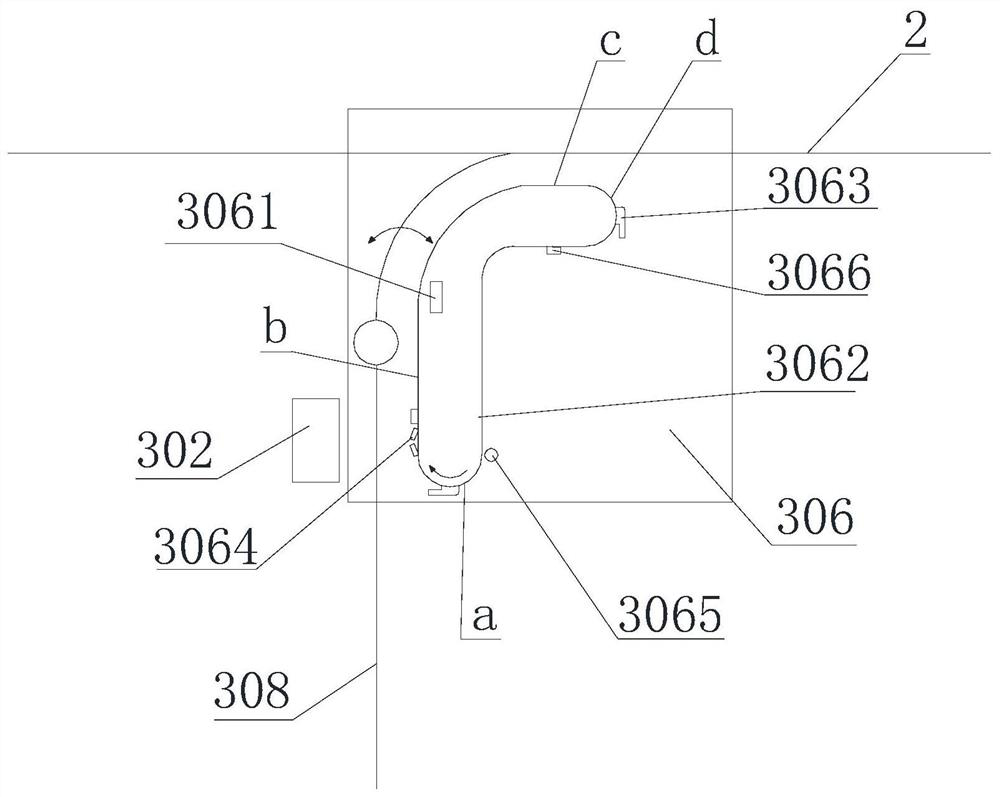

[0047] like figure 2 As shown, the workstation 3 includes an inbound card reader 301, an outbound card reader 302, a touch panel 303, a communication data controller 304, an inbound actuator 305, an outbound actuator 306, a lift button 307, and a rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com