Garment

A clothing, circular technology, applied in underwear, protective clothing, special outerwear, etc., can solve the problems of low blending rate of cellulose fibers, poor quick-drying, difficult to obtain, etc. greasy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

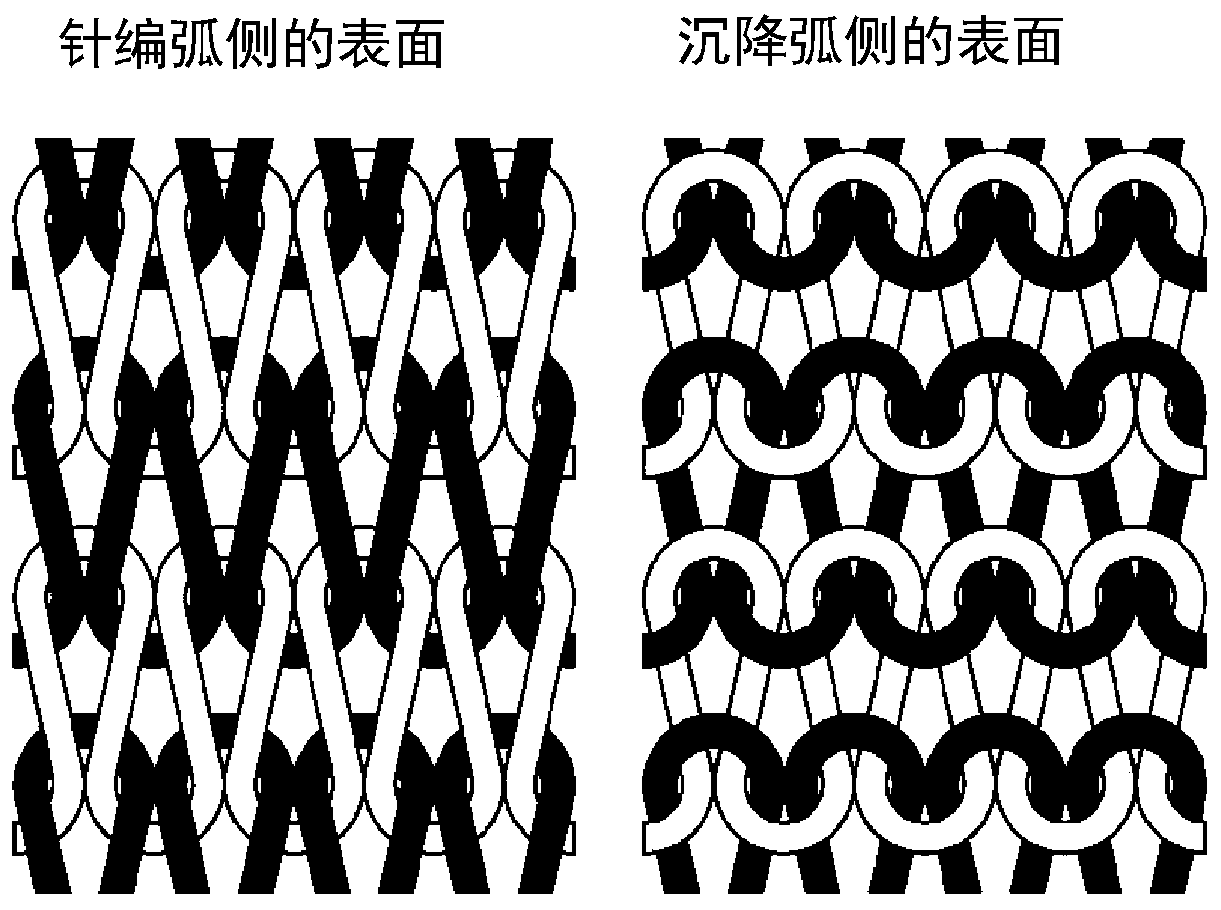

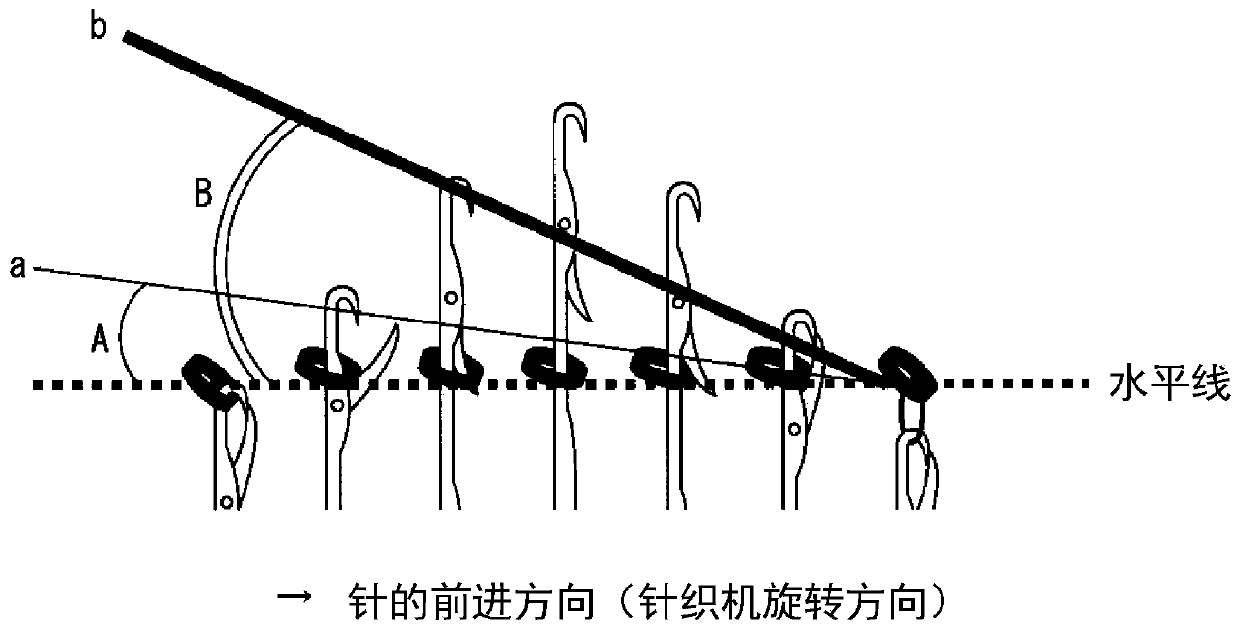

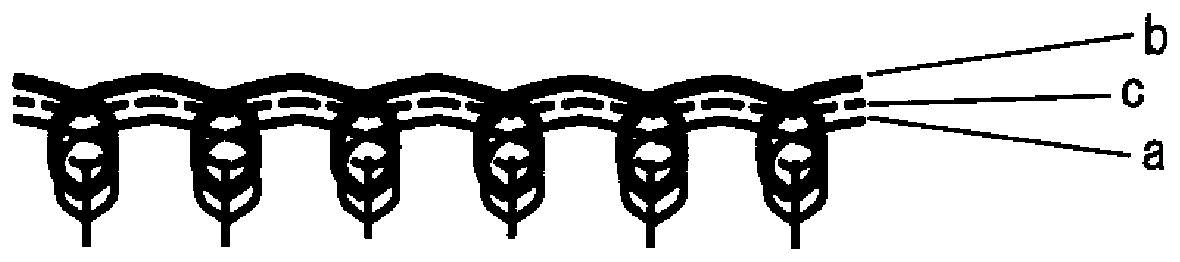

[0114] Use 28G single-sided circular weft machine to image 3 50 counts of polyester spun yarn with a yarn length of 274mm / 100w, polyurethane elastic yarn 22dtex with a yarn length of 98mm / 100w, cupro ammonia long fiber 56dtex30f with a yarn length of 301mm / 100w, using polyester Plated knitting in which the spun yarn is larger than the cupro long fiber and the feeding angle is adjusted. The polyester spun yarn is arranged on the surface layer of the sinker arc side, the polyurethane elastic yarn is arranged in the middle layer of the knitted gray fabric, and the cupro A 3-ply jersey fabric in which long fibers are placed on the surface layer on the knitting arc side. Then, after the usual presetting, dyeing and finishing were carried out. At this time, 2% by weight of water-absorbent processing agent SR-1000 manufactured by Takamatsu Yushi Co., Ltd. was added to obtain a surface on the side where the skin surface adopts needle knitting. A multi-layered circular knitted gray f...

Embodiment 2

[0116] Use 28G single-sided circular weft machine to image 3 The flat stitch weave, the yarn length of polyester long fiber 84dtex72f is 264mm / 100w, the yarn length of polyurethane elastic yarn 44dtex is 94mm / 100w, the yarn length of copper ammonium long fiber 56dtex30f is 280mm / 100w, and the polyester long fiber is used Plated knitting in which the yarn feeding angle is adjusted to be larger than that of the cupro long fiber, the polyester long fiber is arranged on the surface layer of the sinker arc side, the polyurethane elastic yarn is arranged in the middle layer of the knitted gray fabric, and the cupro ammonia long fiber is arranged on the 3-ply jersey knit fabric for the surface layer on the knitting arc side. Then, the same dyeing process as in Example 1 was carried out to obtain a multi-layered circular knit gray fabric with the properties and functions shown in Table 1 below, using the surface on the side of the knitting arc as the skin surface. Next, a T-shirt wa...

Embodiment 3

[0118] Use 32G single-sided circular weft machine to image 3 The plain stitch, with polyamide long fiber 45dtex36f yarn length 238mm / 100w, polyurethane elastic yarn 22dtex yarn length 89mm / 100w, cupro ammonia long fiber 33dtex24f yarn length 250mm / 100w, using polyamide long fiber Plated knitting in which the yarn feeding angle is adjusted to be larger than that of the cupro long fiber, the polyamide long fiber is arranged on the surface layer of the sinker arc side, the polyurethane elastic yarn is arranged in the middle layer of the knitted gray fabric, and the cupro ammonia long fiber is arranged on the 3-ply jersey knit fabric for the surface layer on the knitting arc side. Then, the same dyeing process as in Example 1 was carried out to obtain a multi-layered circular knit gray fabric with the properties and functions shown in Table 1 below, using the surface on the side of the knitting arc as the skin surface. Next, a T-shirt was sewn such that the knitting arc side of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com