Adjustment of clamping and feeding mechanism of semiconductor silicon rod based on the principle of veneer transposition

A clamping mechanism and semiconductor technology, used in grinding racks, fine working devices, manufacturing tools, etc., can solve problems such as lack of surface contact, and achieve the effect of eliminating friction, realizing driving force and good fixation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

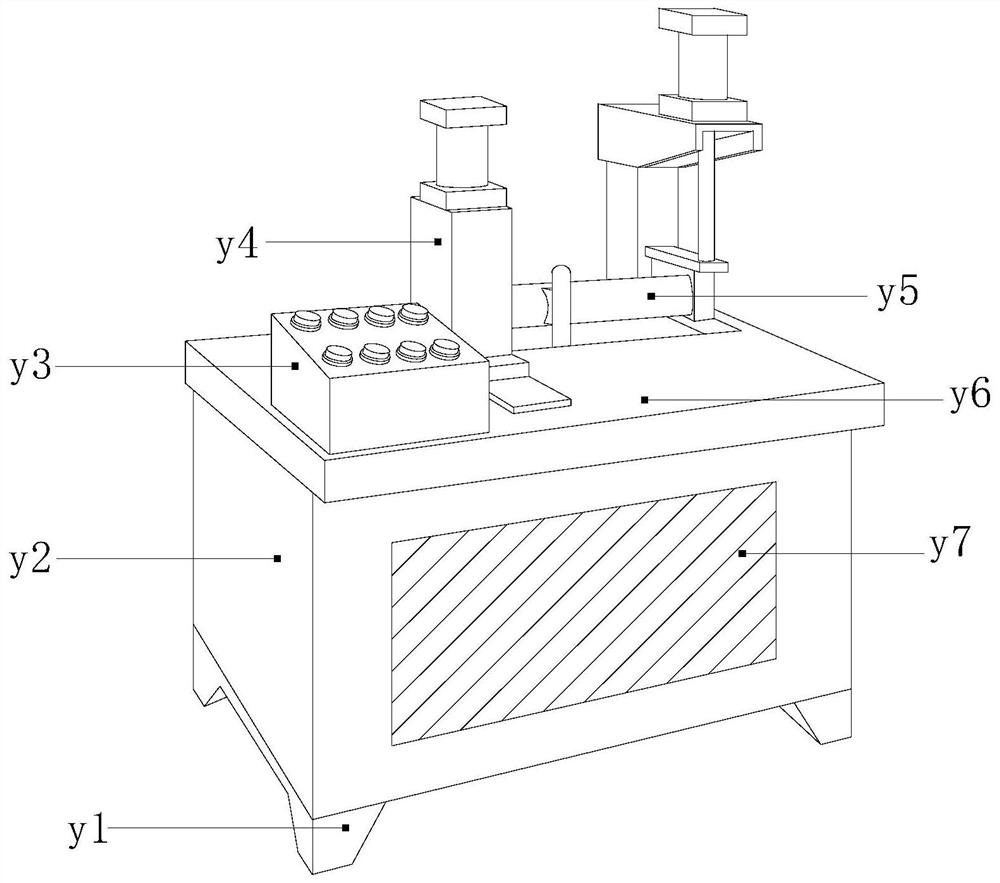

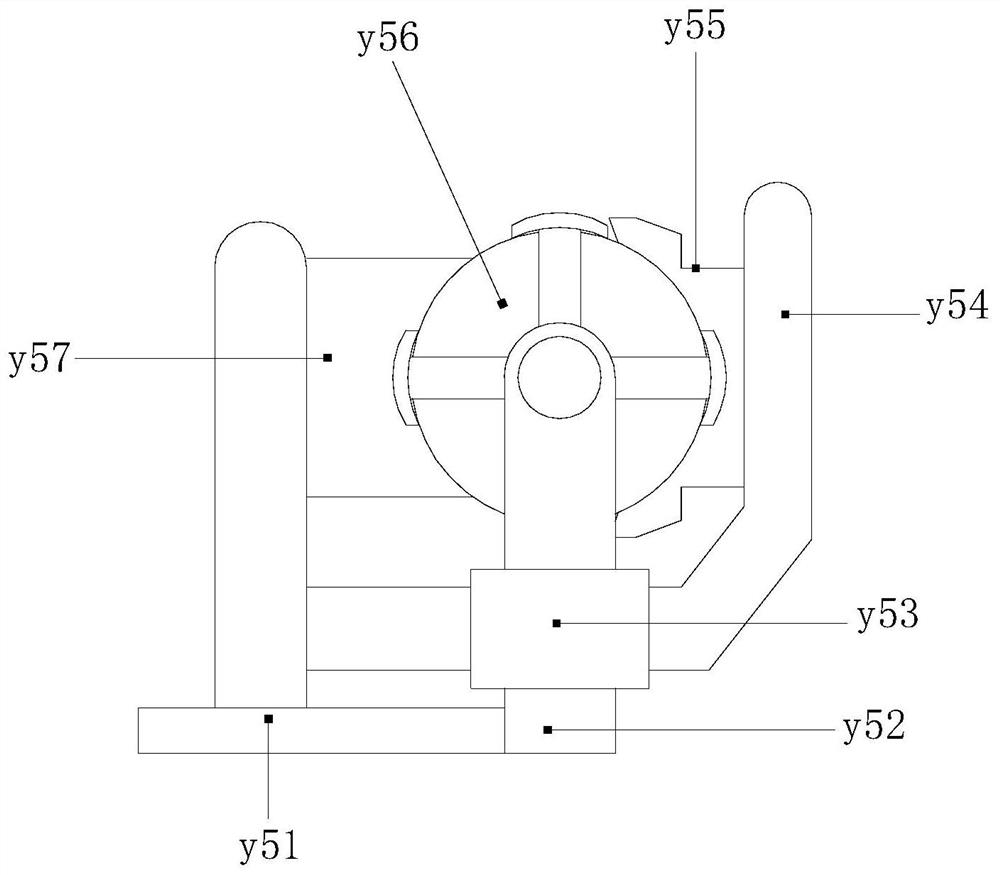

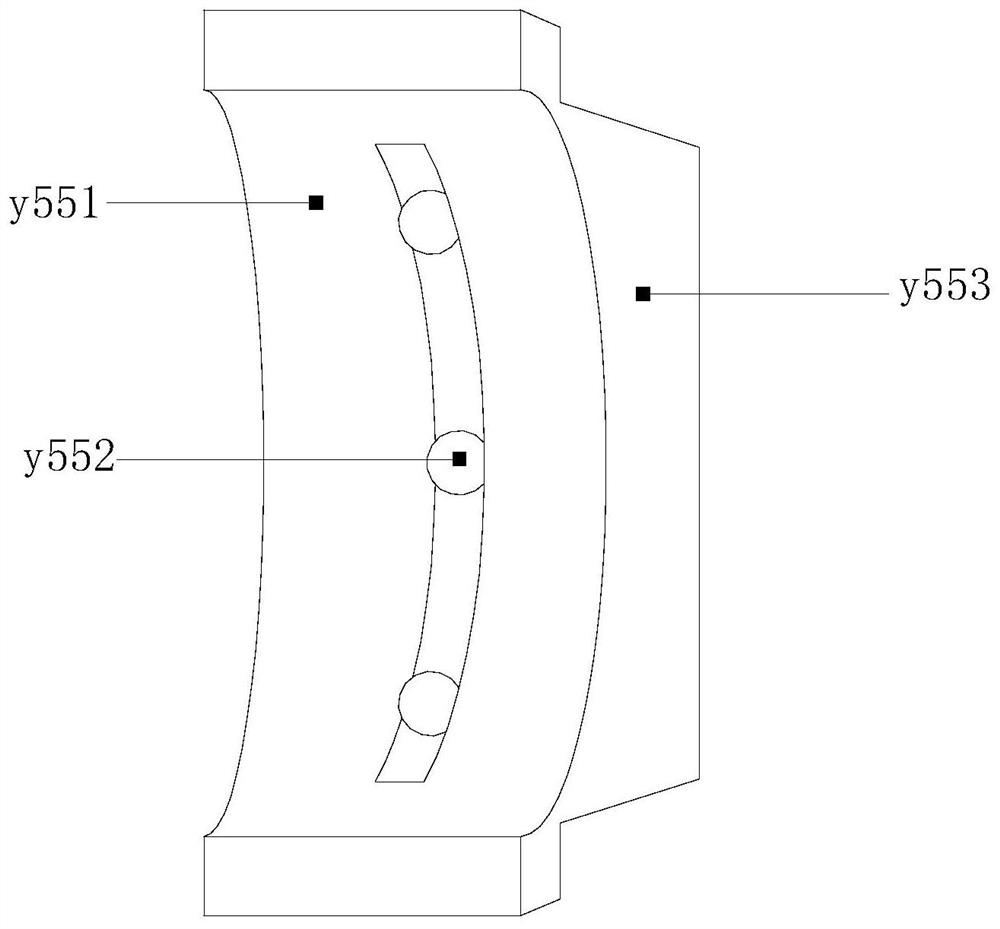

[0029] see Figure 1-Figure 6 , the present invention provides a clamping and feeding mechanism for adjusting semiconductor silicon rods based on the principle of veneer transposition. Groove y7, the heat dissipation groove y7 has a rectangular structure, and is installed on the front end of the host y2 by embedding, the bottom four corners of the host y2 are provided with fixed feet y1, and the bottom of the controller y3 is installed on the surface of the processing platform y6 by embedding At the left end, the right end of the surface of the processing platform y6 is provided with two vertical arms y4, and a clamping mechanism y5 is provided between the two vertical arms y4, and they are connected by buckling. The processing platform y6 has a rectangular structure, And it is installed on the top of the main machine y2 by means of fitting, and the main machine y2 is started by the controller y3, and the silicon rod main body y56 is placed on the clamping mechanism y5 for gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com