Preparing device of carbon nano tube thin film and method

A carbon nanotube thin film and a technology for preparing a device, which are applied in the fields of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve the problems of poor electrical performance transistors, unsuitable for large-area processing technology, and inability to ensure uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in detail below in conjunction with the drawings and examples.

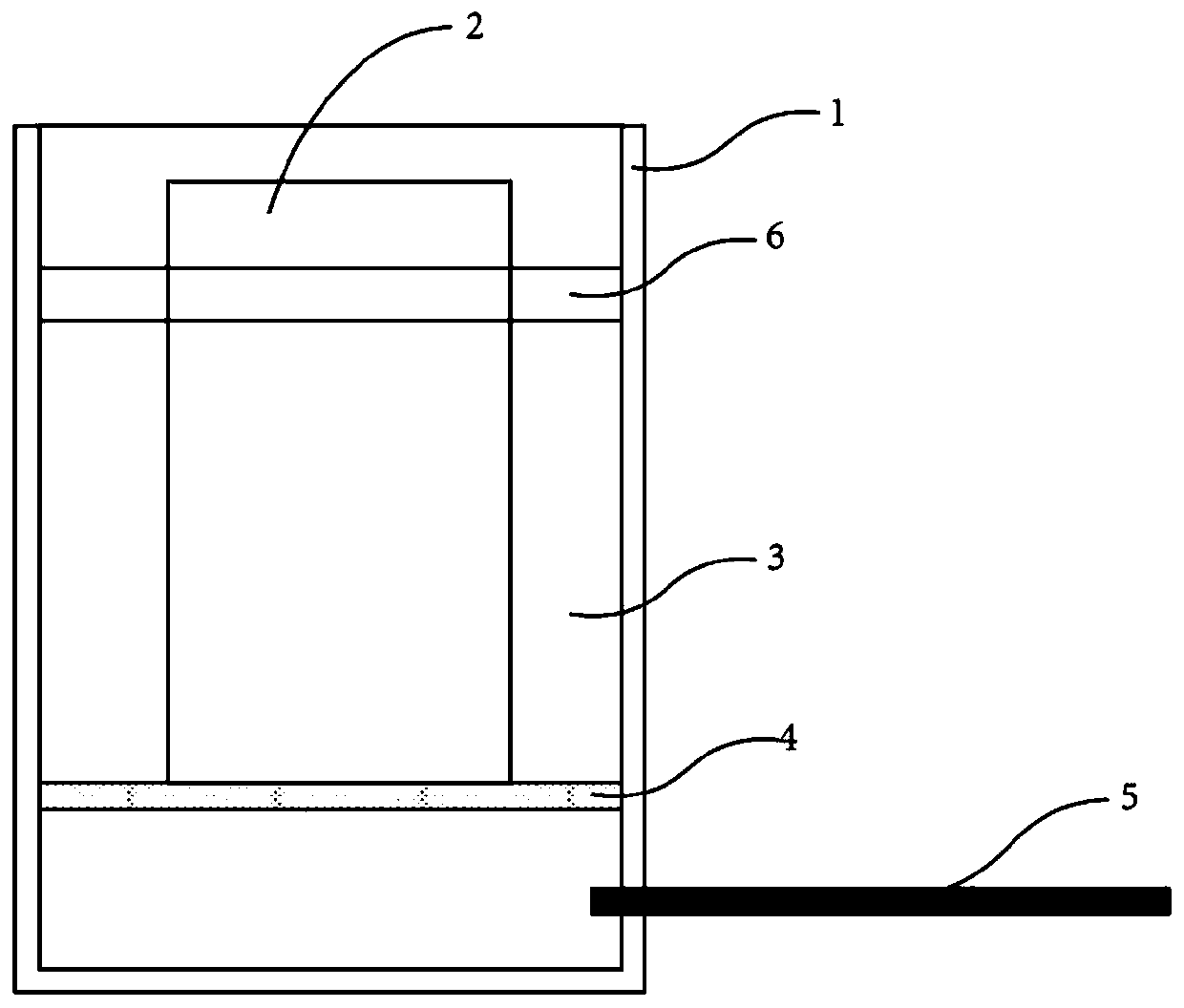

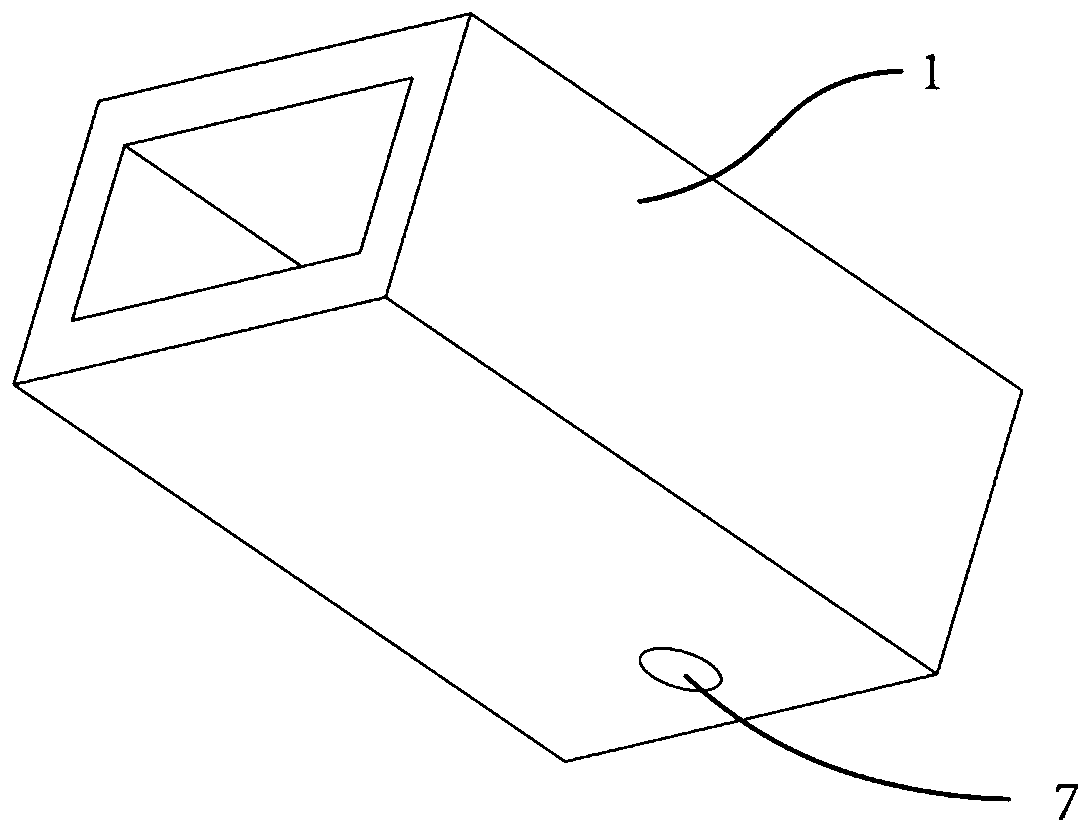

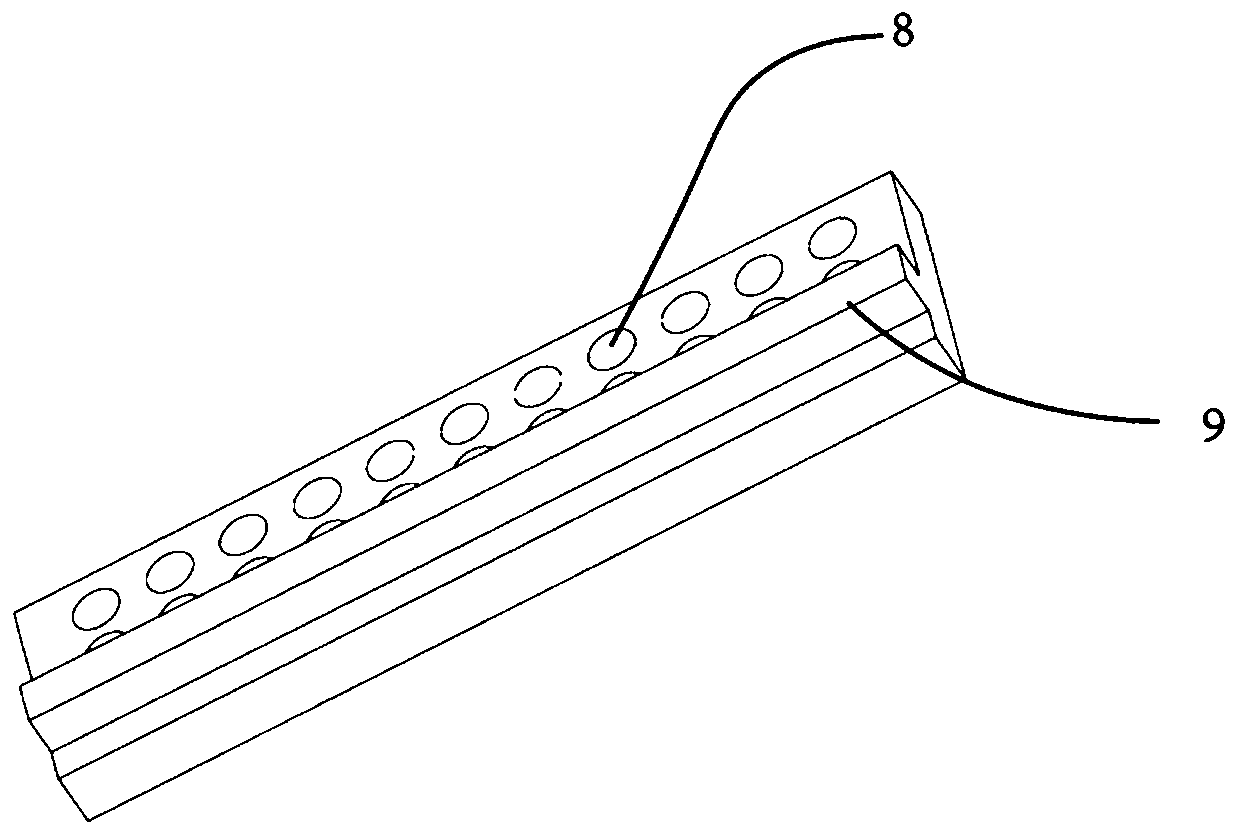

[0030] figure 1 Show the device that the carbon nanotube thin film that the present invention proposes prepares, according to the following figure 1 The structure shown and Figure 2-4 Specific embodiments of the present invention are described in detail.

[0031] like figure 1 Shown, the present invention proposes a kind of preparation device of carbon nanotube thin film, and this device comprises container main body 1, wherein contains carbon nanotube solution 3, and its shape can be set according to the needs such as the shape of substrate 2, workshop land, can be Cuboid, cube or cylinder, etc., adopt the shape of cuboid in this embodiment.

[0032] In the present invention, the formation of the carbon nanotube film is mainly based on the change of the liquid level in the container 1. In order to ensure that the liquid level drops gently and for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com