Sequencing batch anaerobic digestion equipment based on thermal hydrolysis and membrane separation and using method of equipment

A technology of anaerobic digestion and thermal hydrolysis, which is applied in chemical instruments and methods, pyrolytic sludge treatment, water treatment parameter control, etc., can solve the problem of insufficient utilization of thermal hydrolysis sludge solid-liquid separation performance, long residence time , Large reactor volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

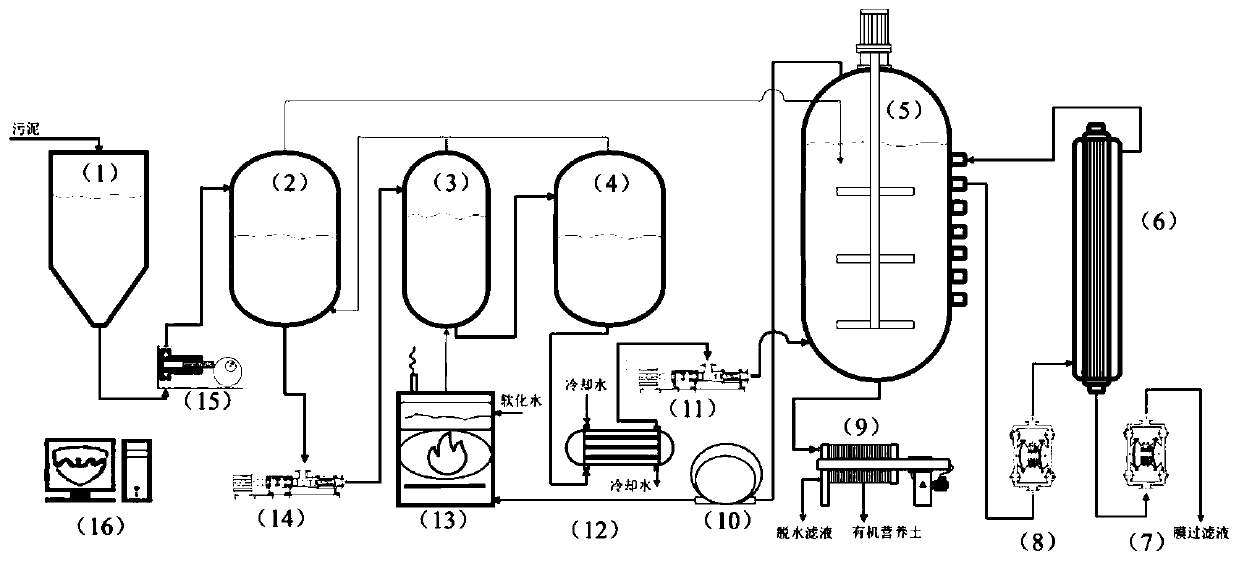

[0025] Attached below figure 1 The sequencing batch anaerobic digestion device based on thermal hydrolysis and membrane separation of the present invention and its application method are described in detail.

[0026] A sequencing batch anaerobic digestion device based on thermal hydrolysis and membrane separation, the device includes a sludge buffer tank 1, a slurry tank 2, a thermal hydrolysis reaction tank 3, a flash tank 4, an anaerobic sequencing batch reaction Tank 5, cross-flow filtration membrane module 6, membrane module water production diaphragm pump 7, digestion supernatant circulation diaphragm pump 8, mineralized sludge dehydration system 9, biogas cabinet 10, anaerobic digestion mud feeding screw pump 11, hot water Sludge decomposing heat exchange system 12, biogas boiler 13, thermal hydrolysis mud feeding screw pump 14, pulping mud feeding plunger pump 15, central control system 16; among them, the sludge buffer bin is connected by a slurrying mud feeding plunge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com