Anchor and extraction integrated method for mining bottom plate rock roadway in deep part coal seam

A technology of coal seam and rock, which is applied in the field of integration of bolting and pumping in rock roadways in deep coal seam mining, can solve problems such as difficult to effectively eliminate high ground stress hazards, inability to timely extract coal seam gas, and easy collapse and deformation of boreholes, etc., to achieve increased Practicality and adaptability, low cost of anchor pumping, and the effect of increasing the tightness of hole sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

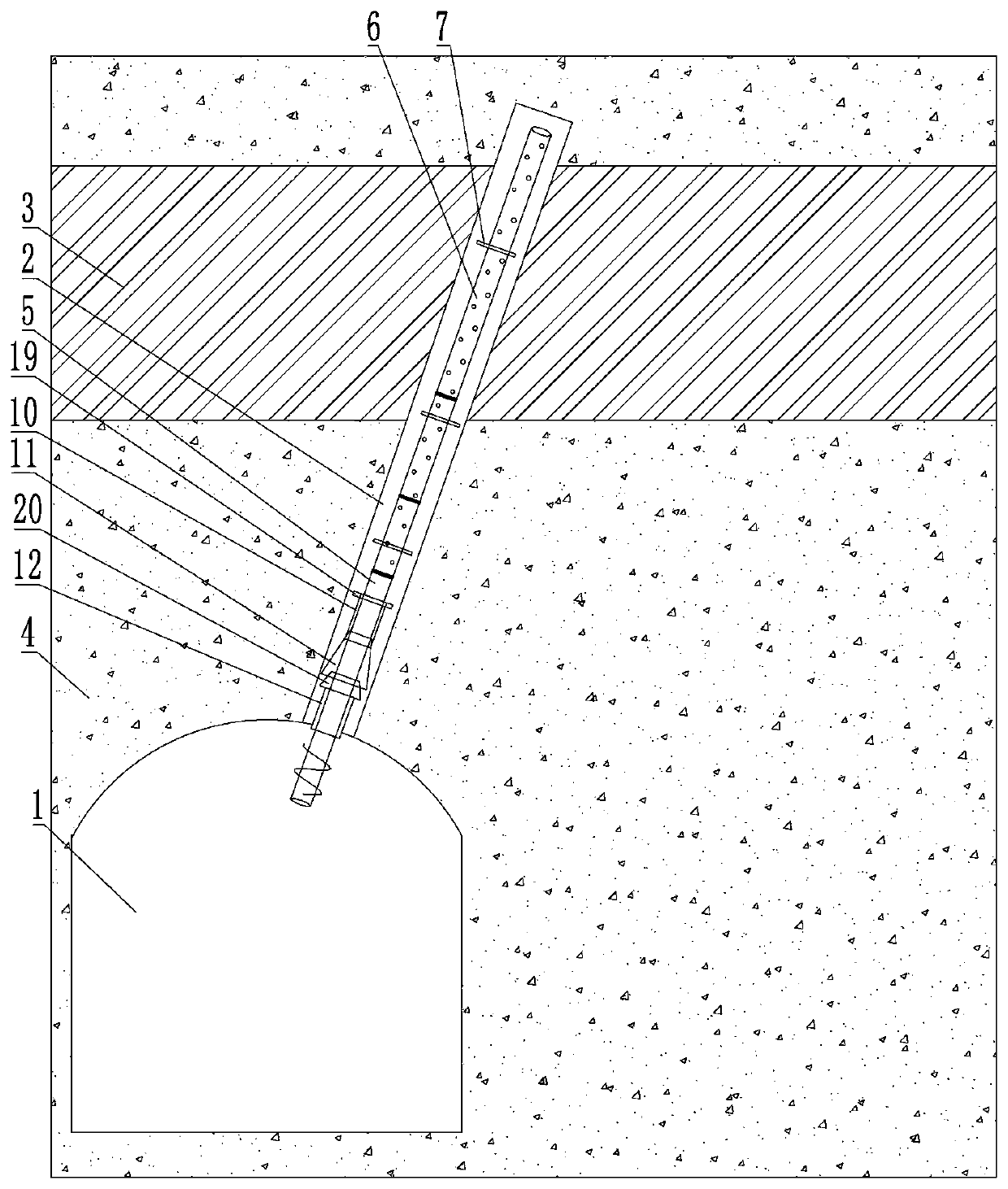

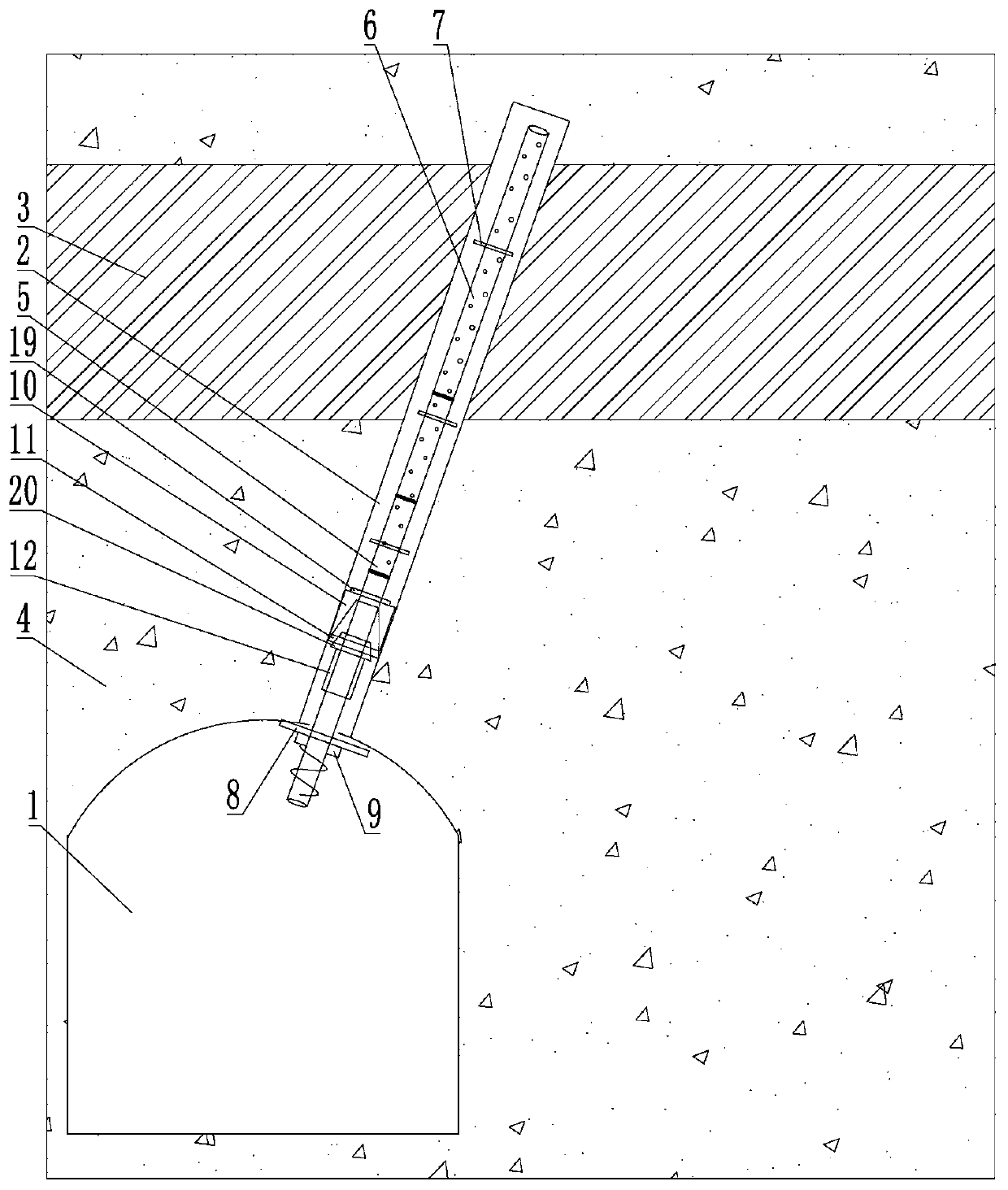

[0041] Such as Figure 1-Figure 3 As shown, the integrated method of bolting and pumping for rock roadway in deep coal seam mining includes the following steps:

[0042] (1) Drilling: use a conventional drilling rig to drill in the rock roadway 1, and drill a plurality of boreholes 2;

[0043] (2) Select a suitable integrated anchor-pump device according to the three indicators of coal seam burial depth, coal seam gas content, and rock mass integrity, and insert the selected anchor-pump integrated device into the borehole 2 to integrate the anchor-pump pump The extraction section of the device is located in the coal seam 3, and the anchoring section of the integrated anchor-pumping device is located in the rock layer 4;

[0044] (3) Anchoring the anchor-pumping integrated device in the borehole 2;

[0045] (4) Connect the anchor-pumping integrated device to the gas drainage pipeline in the rock roadway 1 for gas drainage.

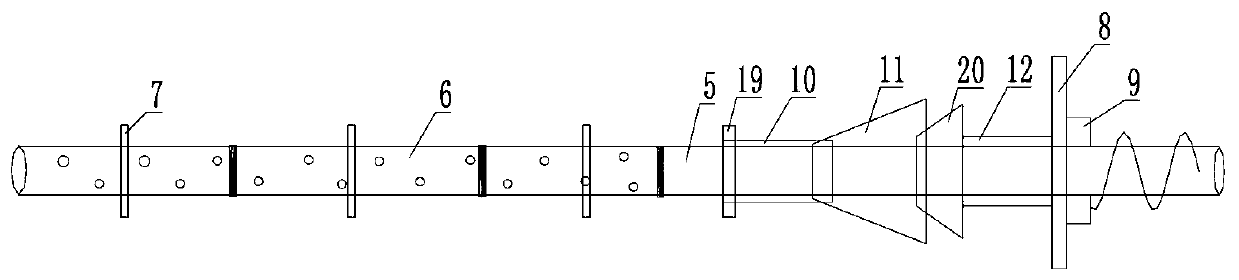

[0046] The integrated anchor and pumping device of...

Embodiment 2

[0053] Such as Figure 4-Figure 7 As shown, the difference from Example 1 is that the anchor-pumping integrated device of this embodiment is a hollow grouting type anchor-pumping integrated device, and the hollow grouting type anchor-pumping integrated device includes a hollow anchor body 5, a extraction flower pipe 6. A number of centralizers 7, steel expansion shell anchor heads 13, hole sealing components, anchor discs 8 and nuts 9, with the end of the hollow anchor body 5 extending into the borehole 2 as the front end, and the hollow anchor body 5 It is composed of several short hollow anchor rods connected with coaxial threads, and the drainage flower pipe 6 is composed of several short flower pipes connected with coaxial threads. 5, the steel expansion shell anchor head 13 has a conical shell structure with a thin front and a thick rear end and an open rear end. The steel expansion shell anchor head 13 is fixed and fixed on the outer circumference of the front side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com